Georg Lemke GmbH & Co. KG is a company with long tradition and renown among the industry. For over 110 years, the company has been known as a manufacturer of exceptional confectionery ingredients that have whet people’s appetites all around the world.

The company supplies products such as marzipan, apricot kernel paste, nougat and filling creams, as well as a grand assortment of processed nuts. The manufacture of products made from almonds, hazelnuts and apricot kernels is the core of the company’s production.

The beginnings of the company date back to 1902 when it was founded by two pharmacists Benno Markus and Georg Lemke in Berlin-Kreuzberg. In 1945 Otto Klühe acquired the company and from that moment on the company has been run by the family Klühe/Hell. 13 years later the production facility moved from Berlin-Kreuzberg to Berlin-Britz (Späthstraße 31/32) and in 1995 the capacity of the factory was expanded by creating a new production and warehouse facility next to the existing production facility in Berlin-Britz.

Safety is a priority

Georg Lemke GmbH & Co. KG continues to improve the products safety in many ways and puts into practice the company’s credo: Freshness and taste are paramount. As a specialized company with refined expertise, the company only uses controlled, prime raw materials. These come from burgeoning regions throughout the world that are visited by the specialists from the company who travel there to assure the quality of the material. This also helps to maintain and cultivate direct business relationships with the local farmers. All products are grown with care, always implementing the latest technology and controlling the quality of the production. “As a producer of food we have a special responsibility to provide safe products to our customers. With our well educated quality control (QC) team, we constantly analyze our process for potential errors. Through the implementation of a IFS system we can provide the most up-to-date production process in this sector of industry.” – says Jan Hell, one of the General Managers at Georg Lemke GmbH & Co. KG. The HACCP concept of Georg Lemke GmbH & Co. KG is applied to assure that all potential risks are successfully thwarted. An additional check of these parameters is proctored at random within the final stages of product control. Since compliance of personnel and operational hygiene is a vital factor in certifying exceptional quality, extensive optical and microbiological checks are also carried out by the laboratory team. This includes not only the survey of the current microbiological status, but also the identification of potential risks as well as the obligatory and routine training of employees.

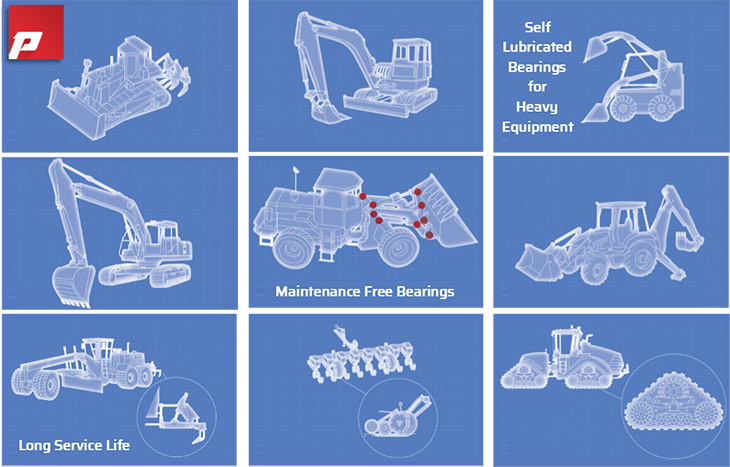

Investing in quality

Each year the Georg Lemke GmbH & Co. KG company invests in equipment, advanced technologies and new production systems. The innovative recipes and production methods set modern standards for the world of sweets. The non-stop supply of deluxe raw materials is the basis of Lemke’s distinctive products. Their careful transport is yet another guarantee of the superior quality of the final products. The raw materials warehouse is up-to-date and allows to achieve the efficiency in on-site sorting. A special selection process by laser and ultrasound ensures the careful selection of the respective raw material needed and prevents foreign substances from contaminating the finished products. The blanching and peeling of the almonds is also made with the state-of-art equipment. Moreover, there are three different roasting methods in use – one being long-term roasting. The method applied depends on the product and the needs of Lemke’s customers. Georg Lemke GmbH & Co. KG is one of two companies which integrated traditional granite rollers as a complement to the modern production techniques in the production of marzipan. In particular, the company’s customers, primarily baking, confectionary and ice cream industry, appreciate the texture obtained by the specialized rollers and the delicate production of Lemke’s raw pastes.

Adapting to the new conditions on the market

The German market has changed significantly over the last five years. An ongoing concentration of the German retail environment can be noticed. This makes it more difficult for the company’s customers to conduct annual negotiations. The retailers and discounters are more and more powerful due to their size. “As we are following the rapid changes in prices of raw material very closely, we can give the best of advice to our customers in regard to when is the best timing to buy. Many of our customers follow this advice and this gives them a competitive position when it comes to their own product calculation.” – says Jan Hell. “Many of our international (and national) customers are open for new product development. Lemke’s R&D department employs three highly qualified product developers, who closely work with our customers. This work ranges from developing brand new confectionery products with Lemke’s products as ingredient to matching existing products.” – he continues. Lemke has a very strong export department with highly qualified people working there. The company communicates with its customers in English, Russian, Polish, French and Spanish. According to the market needs the company works either direct with its export customers or via local distributors and agents. Working with the international customers is a great potential for future growth of the company. Many of these customers are open for new products and they express need for Lemke’s R&D service. The first priority of the company for the coming years is to further intensify the exports, especially in Eastern European countries.

Family values in a family business

The company offers a stable employment and good labor conditions which are the result of a family-business philosophy of the owners. “As a medium sized family business we provide a workplace for more than 130 people. Especially in comparison to larger corporations a business run by its family members stands for a large degree of innovation, flexibility and competitiveness. In our company, we emphasize on the education and development of our own work force in the administration as well as in the production and technical department. We offer a safe work environment with a continuous opportunity for personal education and development. We host the open door policy. The family members running the business always keep an open ear and an open eye to the needs of our employees. As a consequence, members of the Lemke workforce feel valued and respected” – says Jan Hell.

Eco-conscious business

The company implements ISO 14001certified environmental management as well as energy management ISO 50001. The company’s goal is to provide contribution to sustainable environmental management with sensible and pragmatic measures which are always aligned with the bigger picture. The company’s aim is to identify the potential for emission reductions in the early stage of product development. “Since our company is also committed to environmentally-relevant demands, we include, with equal importance, the protection of our environment along with the economic and social matters in all business decisions. The obligation to comply with all relevant environmental legislation is of course adhered to. Our goal is to gently and effectively utilize the resources used. Environmental effects of activities, products, and processes are assessed in order to avoid as much environmental damage as possible. For this purpose, we use the best available technology that is economically justifiable for us. To avoid accidents and negative impacts on the environment, active risk management is employed. We expect our contractors and suppliers to comply with our environmental standards” – says Jan Hell.

Not ashamed to be proud

The company is proud of being awarded with the gold medal of the German Food Society (DLG) for all their marzipan products. Jan Hell also reveals other reasons to be proud of. “We are most proud to be a family owned and family operated business for more than 110 years. In addition to that, we are proud to be among the top market players worldwide within our product range. This is the result of our continuous efforts to constantly improving our services to our customers”, he says.