Acquisition enables ABB to further strengthen gearless mill drive system

business

Zurich, Switzerland, July 30, 2013 – ABB, the leading power and automation

technology group, announced today the acquisition of Alstom’s ring motor

business to enhance its gearless mill drive (GMD) system business. The parties

agreed not to disclose financial details of the transaction.

The business, based in Bilbao, Spain, has about 120 employees and will become

part of ABB’s Process Automation division.

Gearless mill drive systems are used in the mining industry for processing large

quantities of ore to extract metals such as copper, gold, platinum, iron and

molybdenum.

The market for GMD systems is expected to grow due to rising demand for minerals

in emerging countries undergoing industrialization. Deeper mines with more

complex ore bodies and lower ore grades require the grinding of increased

amounts of material to yield the same volumes of metal. GMD systems are designed

to address the need for extremely high ore throughput, reliability and

availability of the grinding circuit.

“The acquisition will combine the leading ring motor product from Alstom with

ABB’s electrical offering for GMD systems, enabling ABB to enhance its position

as a strong vertically-integrated systems provider,” said Veli-Matti Reinikkala,

head of ABB’s Process Automation division. “The acquired expertise and market

strength will provide new opportunities for growth.”

The ring motor product and ABB’s current electrical offering for GMD systems can

only work in combination and are therefore fully complementary. The know-how,

experience and technology that this acquisition brings will enable ABB to

increase manufacturing capabilities and strengthen the ring motor business. In

the long term, end users will enjoy the benefits of ABB’s enhanced product

quality control and system performance.

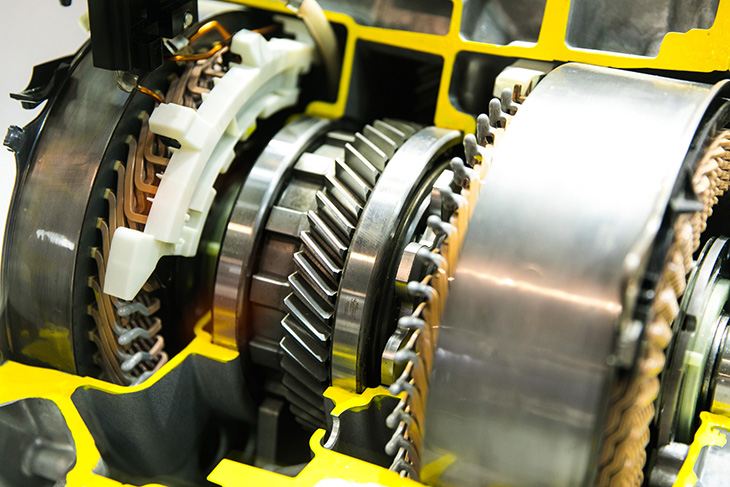

The GMD eliminates all mechanical components of a conventional mill drive

system. By mounting the rotor poles directly onto the mill, the mill itself

becomes the rotor of the gearless motor. The gearless motor - also called wrap

-around motor or ring motor - is a very large synchronous machine which uses

power electronics and a magnetic field to control the speed of the motor

rotation. With no mechanical interaction between the stationary and rotating

parts, there is a significant reduction in the amount of energy used, fewer

parts and higher reliability. The motor power, so far, can go up to 28 megawatts

for such an application. An infographic of the ring motor and further visual

materials can be found

here (http://www.abb.com/cawp/seitp202/49408FA10360FC44C1257BB7004D641B.aspx).

Raw material from the crushing stage is typically fed to SAG (semi-autogenous),

AG (autogenous) and ball mills for further processing to break the rock into

smaller pieces. These mills are large rotating cylinders, from 10 to 15 meters

in diameter. They can grind hundreds of tons of ore per hour. For effective

grinding, these mills rotate at low speeds.

ABB (www.abb.com) is a leader in power and automation technologies that enable

utility and industry customers to improve their performance while lowering

environmental impact. The ABB Group of companies operates in around 100

countries and employs about 145,000 people.