Metso Corporation's press release on December 15, 2011 at 10:00 a.m. local time

Metso has developed a new technology with which municipal and industrial wastewater plants are able to improve their performance and reduce the amount of chemicals used in sludge drying process by even up to one third. The potential users of this innovation include all large wastewater treatment plants in the world.

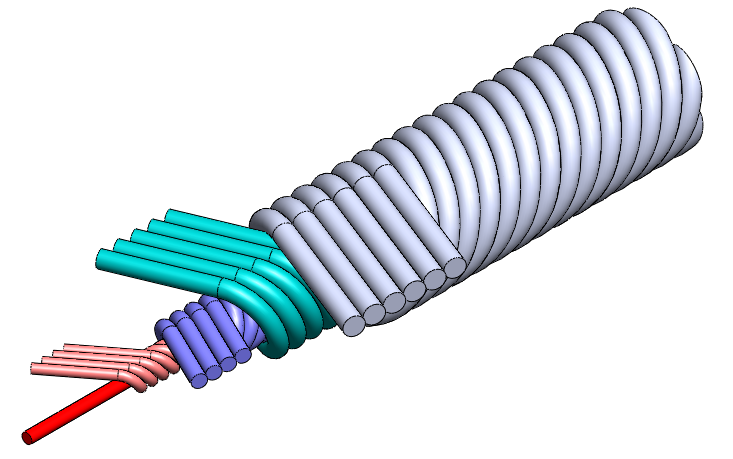

The new technology features an advanced online measurement system for processing sludge, which is an integral part of wastewater treatment. Thanks to a measurement system based on LED and laser technologies, it is now possible to separate dry solids and water from each other more accurately and efficiently than before. In this way, the amount of water treated at a plant can be significantly increased and the amount of chemicals used in the sludge drying process can be decreased by 30%.

In addition to higher capacity and lower chemical costs, savings are gained as the transportation costs of the dry solids separated from sludge decrease. The further use of the dewatered sludge in energy production is also significantly more efficient, as dewatered sludge contains less water than before.

"The new technology developed by Metso offers the world's water treatment plants an opportunity to improve their performance and thus gain major cost savings. A large North American wastewater treatment plant has calculated that it saves even up to 30% in its annual USD 2.5 million chemical costs," says Timo Rantala, Product Manager, Metso's Automation business line.

Global potential

"In the first phase, the new technology will most probably interest especially large wastewater plants in Western Europe and North America, where the level of automation is already high. It is these plants that often have major capacity issues and are under pressure to save costs. Interest in these kinds of solutions is growing in Asia, too," Rantala comments.

In the past five years, Metso has strengthened its role as an expert in wastewater treatment, and is now the market leader in microwave technology measurements used in treatment processes. The know-how is partly backed by decade-long development work, which Metso has carried out in the paper industry and whose results can also be utilized in wastewater treatment.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 29,000 employees in more than 50 countries. www.metso.com

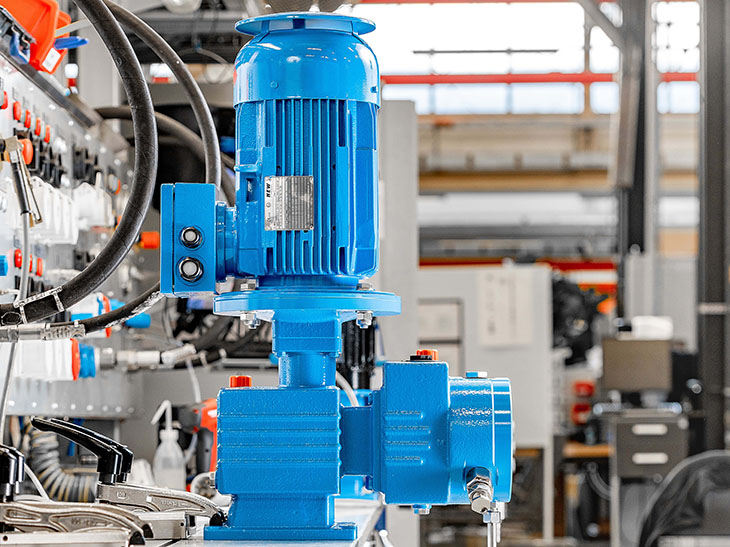

Metso's automation professionals specialize in process industry flow control solutions, automation and information management systems and applications, and life cycle services. The main products include, for example, control valves, automation systems, quality control systems and measurement solutions.