Replaceable, regrindable blades simplify maintenance and increase service life

Those working at the GARS O'Higgins research station, which is operated by the German Aerospace Center (DLR) in Antarctica, are often cut off from the outside world for months at a time: The inhospitable and extreme weather conditions, especially in winter, only allow larger transports in the summer months – a fact which also applies to waste disposal. Previously, this was collected as loose material in containers and, after several months a considerable volume accumulated, which placed further pressures on the already limited space at the station. For this reason, DLR decided to install a waste shredding system and commissioned Erdwich Zerkleinerungs-Systeme GmbH from Igling in Bavaria to undertake this. The company has been developing and constructing systems for shredding a wide variety of materials for more than 40 years and, thanks to its many years of experience with the M450/2-360 twin-shaft shredder, it had the right machine at the ready. The low-maintenance model was modified for the research station in such a way that it could be integrated into the container provided for this purpose in a space-saving manner. The waste which arises can thus be reduced to a fifth of the original volume.

The GARS O'Higgins (German Antarctic Receiving Station) research station, founded in 1991, is operated year-round by DLR in cooperation with the Federal Agency for Cartography and Geodesy (BKG). For the researchers, it is an isolated workplace with the most extreme environmental conditions in the world: wind speeds of up to 300 km/h, temperatures usually in the double-digit minus range and the South American mainland about 1,000 km away. On the other hand, penguins regularly group together at the base of the 9-metre-high antenna, which is used to receive satellite data and measure tectonic shifts. In the winter months, however, this is the only means of contact the station's inhabitants have. Transport flights or mainland visits are impossible during this time.

The waste produced and stored for months takes up considerable space

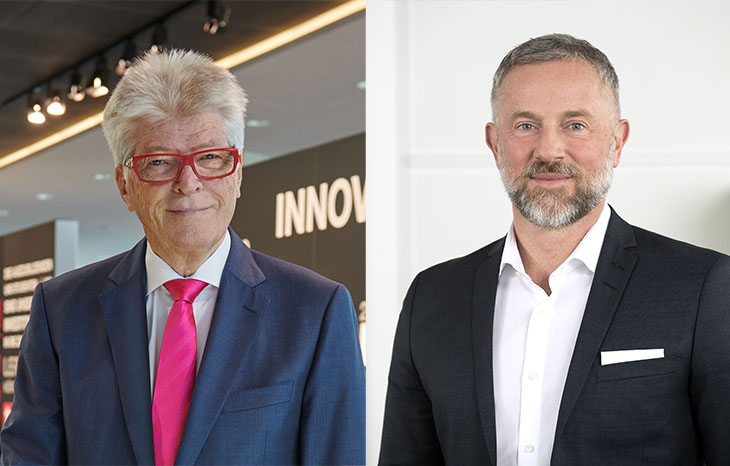

"This also has consequences for waste disposal," explains Harald Erdwich, Managing Director of Erdwich Zerkleinerungs-Systeme GmbH. "Since the adverse weather conditions in winter make it too dangerous for safe transport, the waste has to be temporarily stored at the station for several months." So far, however, waste has only been collected loose and un-shredded in designated containers. Even with only four people, this adds up to a significant amount and, amounting to several tons, takes up valuable space on the research station, which is compactly constructed out of several containers. To simplify waste storage and free up space, DLR therefore decided to install a waste shredding system.

"Several factors played a major role in the design," Erdwich explained. "The plant was to be installed in a container in the waste disposal area and therefore had to comply with certain dimensional specifications in order to be integrated in the most space-saving way possible. It was also important that the shredder be designed for a long service life and still be easily maintained by the staff located there if necessary." To meet these requirements, Erdwich initially carried out trials in its in-house technical centre and, after completing the test phase, reverted to the proven M450/2-360 twin-shaft shredder. The smallest model in the Erdwich series, it has a relatively low drive power of only 5.5 kW, but achieves a high throughput. The very narrow cutting gaps contribute to this, so that the material is cut cleanly and particularly efficiently. The system is also very compact enabling it to be easily installed in the container. The consequent reduction in volume saves space: with the help of the shredder, the waste produced can now be reduced to a fifth of the previous volume, a reduction of 80 per cent.

Manual feed device for greater efficiency

In order to enable the shredding of bulky materials, a manual feed press was installed in addition to the standard equipment. This allows for even larger packaging or containers to be reliably and safely fed into the shredding process without those operating it running the risk of injury. "However, should materials get into the system that are too bulky or unsuitable for the twin-

shaft shredder, the machine has a PLC control with automatic reversing and shut-off," explains Erdwich. "This protects the machine from damage or overload."

Easy maintenance was also a priority during development. To achieve a particularly long service life, the knives were also made of special knife steel. This means they can be resharpened several times and do not have to be replaced immediately when they show signs of wear.

"To ensure that, in the worst-case scenario, the staff stationed in Antarctica do not have to wait six months for a technician to repair the plant, extensive training was also provided in-house on how to handle the machine," explains Erdwich. "In such a special environment, the ease of maintenance and a long service life are major plus points of the twin-shaft shredder." Now, almost 14,000 km from Germany, in close proximity to a penguin colony, the unit will reliably contribute to efficient and environmentally friendly waste shredding in the disposal wing of the German research station GARS O'Higgins.

Further information is available on the Internet at: www.erdwich.com