Cadolto is counted among the global leaders of the modular construction industry. Present in Germany for more than a century and in Poland for a decade, it specialises in erecting hospitals, laboratories, including the largest projects of that type worldwide.

The two projects in question, namely Centre Hospitalier d’Argenteuil in Paris and Federal Centre for Cardiology in Penza, Russia, when put together, take up an unprecedented overall space of 80,000 sqm. Mr Remigiusz Cichocki, Cadolto Poland’s Representative General speaks to Manufacturing Journal about the local peculiarities of this global player.

History in Brief

Cadolto Poland’s success story began exactly 10 years ago. Newly admitted to NATO at the time, Poland was also earmarked to join the EU within three subsequent years. Stability, safety and rapid development were expected to follow soon afterwards, thus bringing in international capital to Poland. Among the investors was Cadolto Fertiggebaud, the worldwide leader of the modular construction industry. The company acted the way the savvy do, carefully that is. Over the first few years the business learned the specifics of the market, tendered for contracts and established rapport with the Clients. Sustainable policy worked wonders: since its inception Cadolto Poland has managed to complete 9 huge independent modular investment projects. Set up in Wrocław in 2006, the company’s sales office has been thriving, too, providing customer service and winning prospective business partners. The company’s headquarters and factory floors are located in Germany; they secure jobs for more than 400 people and have been constantly in operation since 1890.

Focus on Healthcare

“We specialise in healthcare facilities,” says Mr Remigiusz Cichocki, Cadolto Poland’s Representative General. The business has completed the following projects so far, each of which vital for Polish healthcare services: the Euromedic diagnostic imaging unit, Olsztyn, Regional Centre for Blood Donation and Transfusions, Wrocław, intensive care and operating wings at the Jurasz Hospital, Bydgoszcz, operating block at Kołobrzeg Regional Hospital, operating block, diagnostic imaging and central sterilisation units at the Opole Voivodeship Hospital (completed in two stages) and, last but not least, Ursynów Day Treatment Centre, Warsaw. Such prominent investments can hardly pass unnoticed by the industry, which in turn garners new Clientele. “Each Cadolto’s investment turns out to be an event in Poland. We have to bear in mind that modular technology is less popular here than in Germany,” reminds Mr Cichocki. A pioneer as it is, Cadolto has more reasons to take pride, however. “It is not without significance that we render our services to healthcare. Any businessman would find it rewarding. We contribute to the process of developing modern hospital facilities and provide nearly ideal recovery and working conditions for hospital patients and staff respectively,” adds Cadolto’s Representative General.

Daring and Flexible

“Every Client is important for us,” assures Mr Cichocki. With the number of its Polish Clientele growing steadily every year, Cadolto’s impeccable customer service has already managed to bear proper fruit. Being a global player requires flexibility, though. You need to be familiar with local peculiarities, rules and standards if you want to make your presence felt on various foreign markets, all at the same time. Such presence requires that you act quickly and efficiently and that the services you render are simply flawless. This in turn calls for prompt customer care, precise expenditure calculation, competent work staging; all these performed in order to mitigate any construction-related nuisances. “We never shrink from the task. We do our best to serve our Clients in the most professional and responsible manner,” declares Cadolto’s Representative General.

Key Factors Combined

For nearly 40 years Cadolto has been specialising in modular technology, now its sole field of activity and a key to further expansion and lasting success. “How these two, conventional and modular construction technologies, differ? In all honesty, they differ in almost every way,” stresses Mr Cichocki. Modular solutions allow for unrestricted architectural freedom. This enables Cadolto to erect a modular construction using any kind of design, including traditional ones, too. This also means timely completion, value for money, quality and flexibility, a winning combination indeed, especially in the construction of hospitals and laboratories, where technical innovation progresses rapidly, with ever decreasing breathing space in between technological generations.

Abreast of Technology

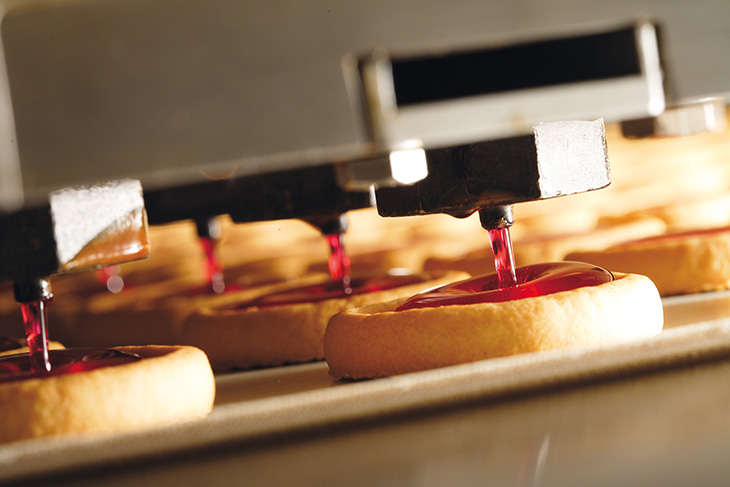

How to complete such projects? Traditional technology requires a construction site together with its building materials, works that affect every one in their vicinity, nuisances to be put up with by the hospital, protracted arrangements, unreliable subcontractors and general contractors buying time and asking for more labour. “Hence we’ve come up with the idea to move the site to our factories,” emphasises Cadolto’s Representative General. Cadolto’s modular construction technology guarantees the highest possible degree of industrialisation to be maintained in the building process. Precise manufacturing workflows are based on tried-and-tested, standardised processes, thereby providing solid foundations for quality, sustainability and the long life of the building. Timely and effective, ninety per cent of the works are carried out in modern facilities, independently of the weather and subject to constant quality controls. Responsible for materials logistics and ordering, the two refined and strictly monitored systems ensure absolute transparency, be they wall construction elements or the tiniest screw.

Setting the Pace

Once the modules have been shipped and assembled, the building is almost ready to use. “We guarantee that all deadlines are duly met. Cadolto needs no more than 6 months to complete turn-key investments up to 5,000 sqm. And projects such as the one we have recently launched in Paris, which takes up a space of 60,000 sqm and requires around 1000 modules to be erected, this one will be executed in only 3 years!” stresses Mr Cichocki. On leaving the factory, the building modules already contain all the equipment, including the entire medical, laboratory and building systems, together with tiles, curtains and façades. Thanks to this unifying of services, transportation is also economical and environmentally friendly, even over longer distances. On site, it is simply a matter of erecting the modules and connecting them to form a building which is immediately accessible to the Customer. “Modular technology is a pleasure to deal in. Key decisions are taken fast, no time is wasted on unnecessary arrangements, there are no serious problems to be faced on completion, either, adds Cadolto’s Representative General.

At the Client’s Convenience

Apart from hospitals Cadolto also supplies highly technologised cleanroom and laboratory buildings. Since 1996, the business has proven construction experience in all research sectors, from medicine, pharmaceuticals and electronics to micromechanics, food technology and biotechnology. „Modular construction technology has no negative impact on cleanroom standards. The latter are specified in detail by the rules and regulations of a given country and are reflected by a relevant plan or design,” elaborates Mr Cichocki. Thus, Cadolto’s specialist designers transform the Client’s individual architectural sketch into a modular schedule of works that integrates necessary equipment and facilities. The building is then assembled on site in a record time. From then on the building is finished and may either serve as a permanent solution or be moved or dismantled at the Client’s convenience.

Larger than Life

“We have every right to be satisfied. Hospitals in France, Germany, Russia and Poland (e.g. Warsaw, Wrocław, Opole) are but a few examples of our comprehensive investments,” says Cadolto’s Representative General. The first on the list is Centre Hospitalier d’Argenteuil in Paris. With a total area of 60,000 m2, this is the largest modular building complex in the world to date. Its construction will be carried out in three stages and is due for completion by the end of 2013. Conventional building methods will be used for the basement and ground floor only, the first, second and third floors will be erected using modules. Approximately 1,000 room modules will be installed.

Cadolto in Russia

Investment projects Cadolto completed in Russia comprise 14 high-tech medical centres erected to date. The largest of these is Federal Centre for Cardiology in Penza, handed over in December 2007. With 14 hospitals 20,000 sqm each, the contract to complete these has become the largest in the history of modular construction technology. Cadolto has risen to the challenge, though. Thanks to its state-of-the-art medical equipment the centre provides high-quality cardiology care for the population of the south-western region of Russia. Each building belonging to the complex is made up of 300 individual modules that were prefabricated at the Cadolto facilities in Cadolzburg and Krölpa, Germany, and by a joint venture partner in Ankara, Turkey. So far, 8 buildings out of 14, have been completed and in only 3 years.

Cadolto in Poland

As for Cadolto’s activity in Poland, it is the following projects that best reflect the company’s huge potential. First on the list comes Regional Centre for Blood Donation and Transfusions, Wrocław, which was erected in only 4 days. It was also the company’s task to integrate the existing structure of the centre into a new, visually harmonious whole. This turn-key investment included 48 modules whose manufacturing, installation together with some finishing touches took only 4 months. In 2008, Cadolto completed a 4-storey children’s intensive care unit at the Jurasz Hospital, Bydgoszcz. The premises that took up an overall floorspace of 2,100 sqm proved no easy task at all. The building was hardly on a level with the adjacent premises and the construction works were not to interfere with everyday activity of the hospital. Kołobrzeg Regional Hospital was in turn composed of 6 different modules, which made 4 operation theatres. With a crane working in unfavourable conditions, the modules were hoisted and carried over the hospital premises to create a brand new block with the state-of-the-art equipment (columns, operation lamps and others). The Opole Voivodeship Hospital became yet another feather in Cadolto Poland’s cap. Completed in several stages, the hospital now boasts a 600-sqm nuclear medicine block developed in 2006, and 4-theatre operation block, central sterilisation, diagnostics and endoscope units handed over in 2009. In 2010, Cadolto made its mark revamping One Day Treatment Centre in Ursynów, Warsaw, in a span of only 5 months. The centre was thus extended by 15 beds, endoscopy unit and 2 operation theatres. It should be remarked that all the projects mentionaed above were designed as turn-key investments and were carried out in a timely, cost-avoiding and quality-oriented manner.