Software company’s enterprise quality hub propels manufacturers’ efforts as champions to restore faith in the quality of “Made in China” products

InfinityQS International, Inc., the global authority on real-time Manufacturing Intelligence and enterprise quality, announced today the 5 th anniversary of its China office, which was celebrated at the 2013 InfinityQS User Conference of China. Throughout the event, customers shared the successes they have achieved while using ProFicient, the company’s global quality hub powered by a statistical process control (SPC) analysis engine. Based on these success stories, it was clear that manufacturers in China are determined to restore faith in the quality of “Made in China” products through the use of advanced tools and technologies.

Customer Success Stories

The customer stories below represent leaders in quality from some of the foremost manufacturers across various industries, producing differing products. However, they all have a single goal in common— to improve quality with the most effective tool. With InfinityQS’ ProFicient, these companies have seen results such as decreases in scrap and expenses, and increases in profits, employee skill levels and quality awareness.

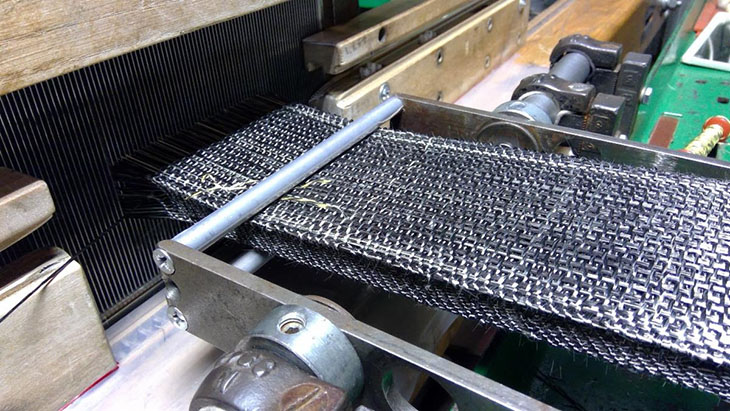

• Bohai Piston (Shandong): After implementing real-time SPC through InfinityQS’ ProFicient software in 2009, Bohai Piston has experienced remarkable improvement in its level of quality control. On a single product line, the average rejection ratio decreased from 0.76 percent to 0.44 percent in just six months. Due to this success across its manufacturing processes, the company was awarded “the national quality prize,” and attributes it in large part to the use of InfinityQS’ real-time SPC software.

• EMBRACO (Beijing): Since incorporating InfinityQS’ real-time SPC software five years ago, EMBRACO’s products have continued to win customers’ trust and loyalty with consistent and reliable quality. To achieve this, EMBRACO’s quality teams rely on ProFicient’s automated alarm functionality, which will automatically detects when a data value falls out of specification. When this event occurs, the software will immediately set off alarms and send predetermined alerts so that appropriate operators can respond to the events before problems occur—even remotely—ensuring consistent product quality.

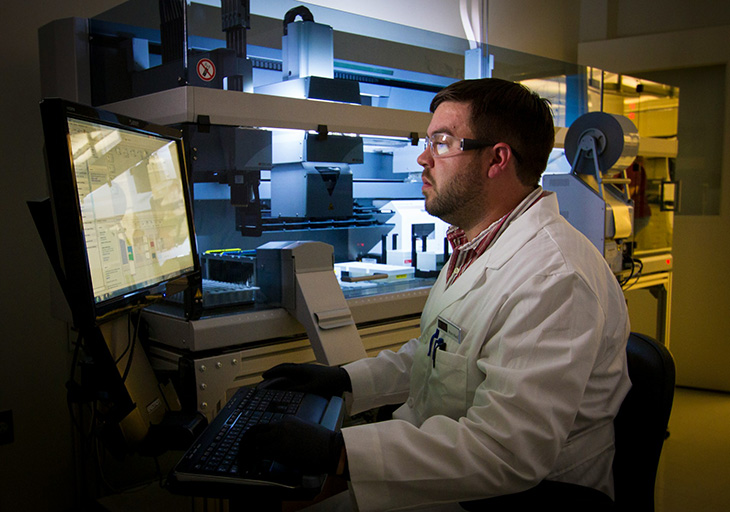

• SanDisk (Shanghai): In the three years that SanDisk has used InfinityQS’ ProFicient, it has seen continuous upgrades and advancements in the product, many of which were direct responses to SanDisk’s own inquiries and requests. This is an important foundation upon which SanDisk can continue to innovate in its own development, and offers the confidence in knowing that a proven, real-time SPC provider will continue to provide the necessary tools and technology for SanDisk to push farther in quality control.

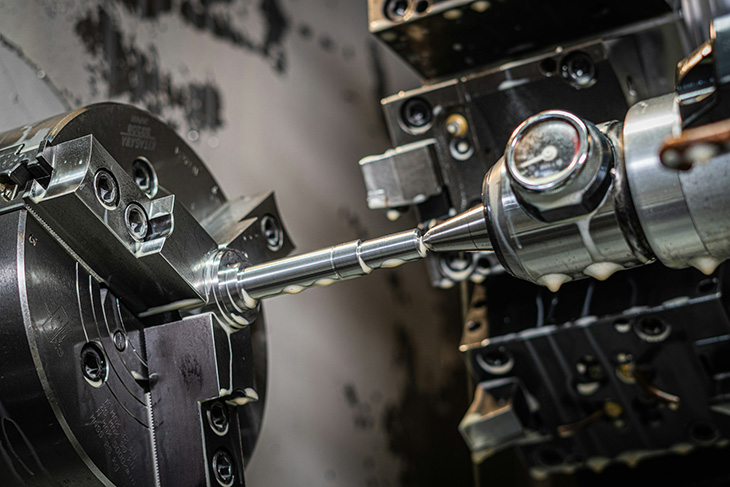

• Singu Keller Automotive Cold Forming Parts (Beijing): In just five years, Singu Keller has realized the benefits of using InfinityQS’ real-time SPC software, ProFicient. The software has enormously promoted the quality control of the company through precise quality management to eliminate waste and reduce quality costs. ProFicient’s visualized analytical tool enables site workers to foresee and pre-control quality, while the diversified data collection and integration abilities have helped Singu Keller determine the quality solutions that can best suit the company.

Elaine Wong, general manager, InfinityQS China, said, “InfinityQS strives to help enterprises find potential loopholes in their production processes by bringing the most advanced SPC methods and tools to China from around the world. InfinityQS recognizes that ‘Made in China’ is not simply a slogan, but a spirit of dedication among quality professionals across the country that has been growing for over 20 years, and producing outstanding manufacturers who are dedicated to delivering high-quality products. By following the lead of these manufacturers, others across China can reject the ‘low quality and low price’ labels and again become more competitive in the global market.”

ProFicient is a proven enterprise quality hub powered by a centralized SPC analysis engine. With flexible cloud-based or on-premise deployment options, ProFicient enables manufacturers to proactively monitor, analyze and report on Manufacturing Intelligence to improve quality, decrease costs and make more strategic business decisions.

Related Links:

About InfinityQS: www.infinityqs.com

For more information about the ProFicient Global Quality Hub: www.infinityqs.com/software