Haldor Topsoe A/S, a world leader in catalysis, and FLSmidth A/S, a leading supplier of equipment and services to the global cement and minerals industries, today signed a cooperation agreement that marks the beginning of a joined global effort to commercialize a newly developed unique catalytic filter bag technology.

The product will carry the brand name EnviroTex(TM) catalytic filter bags and is capable of removing dust, volatile organic compounds and nitrogen oxides in one integrated and cost-effective process. A long list of industries including cement, power, biomass, waste incineration as well as glass and metal production are the target customers and the global commercial potential is huge.

Over the past four years the two parties have been working closely together on developing the EnviroTex(TM) technology. As part of this effort the product has been thoroughly tested and proven efficient for several industrial applications.

A strong fit of competences

"Developing this product has been a combination of the very best that Topsoe and FLSmidth have to offer from an R&D perspective. By combining FLSmidth's expertise in filtration in industrial processes with Topsoe's leadership in catalysis, we have created a unique product that will allow customers to meet increasingly stringent environmental legislation at a fraction of the operating cost that even the best available technologies offer today," says Bjerne S. Clausen, CEO in Haldor Topsoe.

The key differentiating factor about the patent-pending catalytic filter bags lies in the fact that EnviroTex(TM) consists of three layers of filter fabric. Each layer contains a tailored catalyst optimized for the removal of specific kinds of compounds from the off-gas that passes through it.

"The three layer structure is unique. Not only because it provides us with the flexibility to tailor different catalytic combinations for different industries. It also makes it possible to handle the removal of several critical compounds in one integrated process. This can significantly reduce the cost of off-gas cleaning because today's standard is to use separate stand-alone systems to address removal of specific compounds. This translates into complexity and higher customer operating cost", says Bjerne S. Clausen.

Leveraging existing strengths

Fabric filters are used across a variety of different industries today of which cement and minerals represent a large market segment. In many applications they are used as a final purification step to remove particulate matter from the flue gas. FLSmidth has been world market leader for many years in this field with extensive experience and in-house knowledge on how to design, manufacture and operate fabric filters for a broad range of industries, and possess detailed process integration know-how.

"The beauty of this collaboration is that we can fully leverage each other's strengths and market presence and efficiently target a global market opportunity. EnviroTex(TM) catalytic filter bags allow customers to upgrade their environmental equipment to fulfill tightened legislation at low cost and with minimum influence on existing production equipment," says Thomas Schulz, CEO in FLSmidth and continues:

"Initially we believe the US market will benefit from the product, because cement producers here are faced with immediate challenge in order to meet new regulatory requirements that have been issued by the US Environmental Protection Agency and will take effect 1 September 2015. In the longer term China may hold an even greater market potential as stricter emission legislation is also being imposed there. Therefore EnviroTex(TM) adds to both companies' product lines being one of many solutions to the need for emissions reduction and improved energy efficiency".

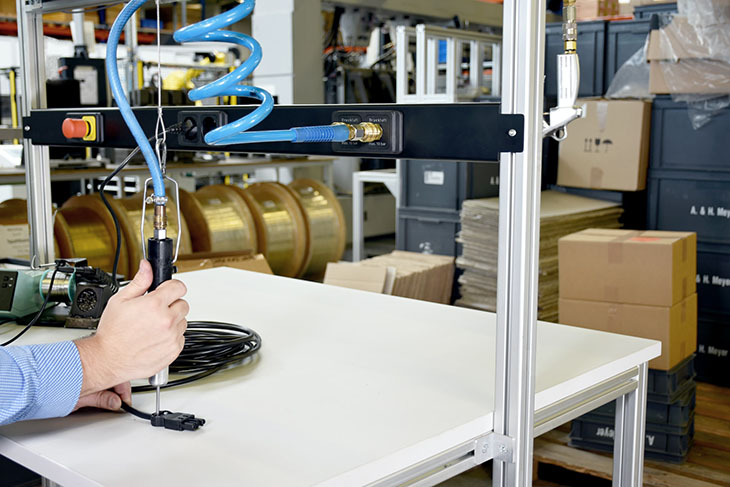

As part of the agreement between FLSmidth and Topsoe, the new product will be manufactured at FLSmidth's bag production facilities in Georgia, USA. The high quality filter bags will then be catalyzed and assembled at Topsoe's catalyst production site in Houston, Texas. In fact Topsoe's production site will be expanded with an entirely new production line dedicated to the production of EnviroTex(TM) catalytic filter bags. The goal is to complete construction of this facility by end-2015.