The next generation of micro-welding technology: A special tungsten electrode less than 1 mm in diameter with a long service life enables reproducible welding results of the highest quality

The miniature range with workpieces with a material thickness of merely 0.1 mm is considered one of the most demanding welding tasks in industrial processes with partially automated or fully automated manufacturing. Because the complex machining processes take place in the smallest possible space, high-quality weld seams or spot welds occur for the fine geometries, without producing thermal distortion, without generating undesired colour tarnishes, or without having to accept changes in the microstructure of the metal. Premature wear of the electrode required frequent grinding and thus an unwelcome interruption of the workflow and of the reproducibility of the processes. Consequently, Lampert Werktechnik GmbH, in collaboration with the Gesellschaft für Wolfram Industrie mbH has developed a TIG electrode that has been especially adapted to these extreme requirements: the PUK-Star. This electrode makes it possible to set ultra-precise tacking pulses, even for filigree components with a material thickness of 0.1 - 2 mm, and yet it still prevents burning of the material. The electrode is characterised by optimal ignition properties at minimal short-circuit times in fast succession, yet it offers an outstanding service life that exceeds the previous top values by a multiple factor. Any weldable metal can be reliably processed in this manner.

For fine welding, a faultless weld seam can only be achieved with minimal and precise heat input via a controlled welding pulse, and this in turn imposes high demands on the tool. In particular, for the electrode this is an extreme thermal load, which it must withstand in spite of its minimal size. When working with a low material quality conventional electrodes form cracks, or in the worst case they break off. "However, for micro welding reliable reproducibility of the results is of essential importance and to achieve this, each component of the welding process must work optimally", reports Jürgen Fuchs, Operations Manager at Lampert Werktechnik GmbH. "If this is not the case, welding error or destruction of expensive electronic components, such as integrated circuits or sensitive sensors, can irreparably damage the workpiece. Therefore, together with Wolfram Industrie we have been working on improving the electrode." The goal was to develop a TIG electrode with a long service life, favourable ignition behaviour, in order to guarantee a uniform, high level of quality.

Meets the highest development requirements in the smallest space

For example, in the area of measurement technology and sensor technology, but also for prototyping in the automotive industry, often extremely thin and heat-sensitive points must be welded. In this regard the quality of the electrode plays a central role in producing a faultless weld seam. "To meet these high requirements the Gesellschaft für Wolfram Industrie mbH has been supporting us ever since our company was founded ", states Martin Beckmann, Managing Director of Lampert Werktechnik GmbH. "Due to the collective know-how of both companies we have been able to continuously improve the qualities of these central components in the welding process." On the basis of these experiences both companies in close collaboration developed the PUK-Star. This electrode consists of a tungsten alloy especially adapted for industrial manufacturing; it can be compared to a pin with a diameter ranging from 0.6 to 1.0 mm. Thanks to the improved geometry and condition of the electrode the PUK-Star is characterised both by an outstanding service life and favourable ignition behaviour.

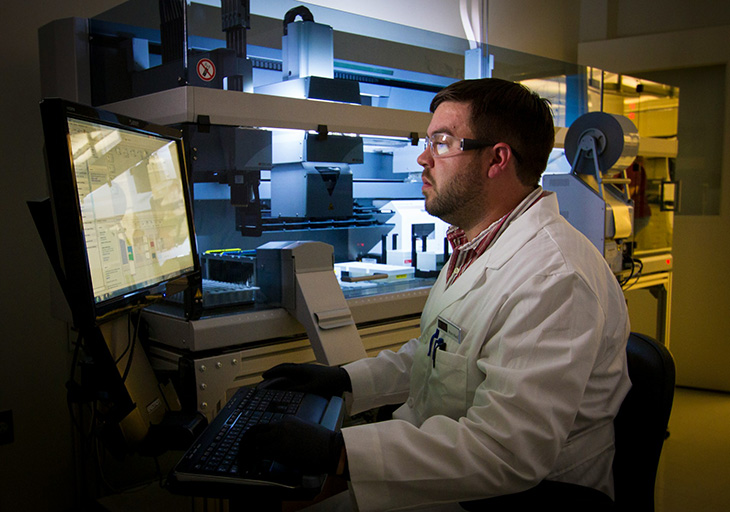

In an initial development step the crucial welding parameters of the optimal electrode were determined through a number of test series – these key parameters are bevel angle, roughness and material density. To do this, Wolfram Industrie used high-resolution microscopes to analyse the test results with the highest possible accuracy. The particular challenge in developing the PUK-Star was the required minute dimensions of the electrodes", explains Matthias Schaffitz,Managing Director of Wolfram Industrie GmbH in Switzerland. "For example, we had to use magnifying optics and surgical tools such as needle holders for the analysis and machining." Based on these test results we were able to optimise the condition of the electrode, as well as the composition of the alloy. Thanks to these adjustments the PUK-Star improves a large bandwidth of different industrial manufacturing applications – from production with an upstream tacking function to manufacturing of thermal elements for measuring high temperatures in the semiconductor industry. The electrode leaves no particles whatsoever on the workpiece, as we were able to verify through test runs in series with 500 spot welds and a subsequent X-ray procedure.

Additional development work and close cooperation

However the collaboration of Lampert and Wolfram Industrie extends beyond development of the PUK-Star. "Due to the close cooperation, there is a constant flow of new ideas that can be used somewhere else", reports Schaffitz. "For instance, Lampert was able to provide helpful impetus for the processing of precious metals and to help us in this area. Consequently, we look forward to additional exciting and targeted projects to advance the research in the field of welding technology." One example is the work that is currently underway on a sustainable recycling process for responsible handling of the valuable raw material tungsten.

In return for this development work, Wolfram Industrie supports Lampert as a universal service provider in the area of TIG electrodes. For example, the tungsten specialists are manufacturing the newly developed PUK-Star themselves and also undertake the specific grinding of the electrodes. "In the Gesellschaft für Wolfram Industrie mbh we have found the ideal symbiosis of electrode supply and research competence that we need for our high-quality, precision welding devices", summarises Beckmann. "The regular collaboration results in significant further development of the existing electrode quality." Diagnosis of the welding processes with scanning electron microscopes or spectral analyses as needed, are also included in the portfolio offered by Wolfram Industrie. In this manner a weld seam that is always optimal, even for the most complex and minute industrial applications, is always guaranteed.

More information at: www.wolfram-industrie.de and www.lampert.info