Manufacturing facilities require well-functioning HVAC systems to maintain comfortable temperatures for workers, manage the climate requirements associated with specific tasks or products, and achieve the necessary ventilation for safe working conditions. How can you ensure your system is efficient and productive?

1. Change the Filters on the Appropriate Schedule

Most commercial HVAC filters need quarterly changes. However, consider doing it more often if your manufacturing environment is excessively dusty or your production facility has above-average cleanliness requirements.

Perhaps you’ve just moved into a different building, installed a new HVAC system or are unaware of the best filter-changing schedule. Check the filter monthly and see how long it takes to get dirty.

Changing the filter at the proper intervals is an excellent way to reduce strain on the system and maintain high air quality in the manufacturing facility. Clean filters also make the equipment as energy-efficient as possible.

2. Test and Calibrate Thermostats When Necessary

An inaccurate thermostat may seem like a mere annoyance, but it can have undesirable ripple effects. For example, you may pay 9% more in energy costs with a thermostat off by only 3 degrees.

Try a simple test by running the heating for 15 minutes and then comparing the thermostat’s reading with what a thermometer says. If the two don’t match, use a calibration screw to address the problem. Alternatively, reset the thermostat to see if that addresses the discrepancy.

Another quick potential fix is to use canned air on the sensors. Sometimes, dust can block them, resulting in inaccurate readings. Prioritizing some of the fastest and simplest solutions before assuming you’ll need to replace the thermostat is the best approach.

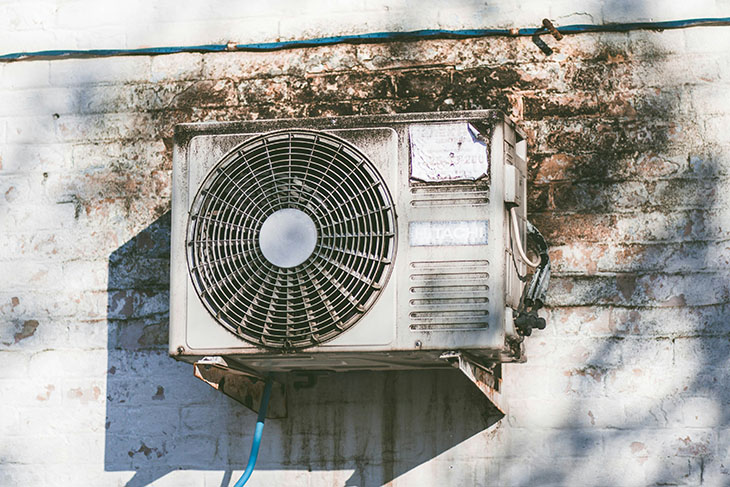

3. Keep the HVAC System Well-Maintained

Scheduling regular tuneups for your manufacturing facility’s HVAC system is one of the best ways to prevent future issues. Once problems appear, there may be a gradual worsening of unaddressed symptoms.

You may notice efficiency losses after reviewing system metrics and utility bills across the last several months. Fortunately, people can make the equipment up to 15% more efficient by changing or cleaning its filter. A full or clogged filter can also result in more dust in the environment, posing various potential challenges in manufacturing environments.

A technician can also address other abnormalities, such as the HVAC running too frequently or being excessively loud. Sometimes, replacing a problematic system makes more sense than continuing to repair it. Your professional will consider factors such as the equipment’s age, the scope of the problem, how often the issue happens and how easy it is to get spare parts before advising you whether it’s best to replace or repair it.

4. Be Open to Tech-Centered Solutions

A growing number of technology vendors target HVAC systems with their offerings. Statistics suggest using artificial intelligence to improve the equipment’s productivity could lengthen asset life by 50% and reduce energy costs by 25%.

Similarly, Internet of Things sensors predict impending issues, often several days before humans notice performance reductions or other unusual developments.

The impressive possibilities associated with advanced technologies such as these do not mean there’s no longer a role for people to play in keeping their HVAC equipment running well. After all, even the most advanced technologies can still fail or reach incorrect conclusions. Combining professional judgment with carefully developed, thoroughly tested products is a smart way to begin using tech-based solutions and anticipating positive results.

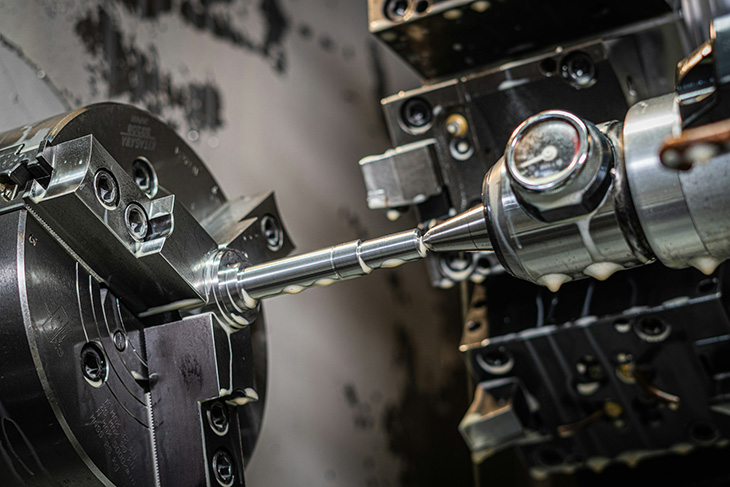

5. Understand Time’s Effects

Even the most dedicated efforts to maintain a system’s efficiency and productivity cannot wholly counteract what gradually happens as it ages. For example, mechanical moving parts wear down the fastest, and refrigerant coils become less efficient as the liquid circulates and coats them.

Consider keeping detailed records of when parts are changed and when maintenance procedures occur. Relatedly, evaluate whether environmental conditions, overall running time or other factors connected to your manufacturing facility might accelerate how time impacts your system and how it runs.

Consider using a digital, cloud-based system to track all this information. Set notifications that alert you about parts nearing the end of their useful life and allow plenty of time to source replacements. Keeping the information in the cloud is especially beneficial when someone must oversee HVAC systems at numerous manufacturing plants spread across the state, country or world.

Read your HVAC system’s owner’s manual to learn about applicable warranties and what they do or do not cover. Most have time-based statistics about how long coverage exists for different component categories and mention whether specific circumstances void the protection.

Create a Proactive Culture

Besides technicians, facilities managers and others individually adopting these suggestions, people in authority should strongly consider doing what they can to make proactiveness a company norm.

Workers will collectively contribute to HVAC equipment that stays efficient and productive when everyone at the manufacturing facility understands it’s always better to prevent emergencies through maintenance and immediately address issues instead of ignoring them.