Neuffen, March 2023: Frequently small and inconspicuous, burrs nevertheless have considerable potential for causing damage. These remnants from the manufacturing process repeatedly lead to problems ranging from avoidable quality defects to product recalls. Beyond this, many industry sectors place strict demands on burr-free components, as well as cleanliness and surface finishing quality. Solutions which have been adapted to the task at hand are indispensable in order to be on the safe side in this regard. As the internationally most significant information and procurement platform of its kind, DeburringEXPO showcases relevant solutions. The bilingual expert forum integrated into the leading trade fair for deburring technologies and precision surface finishing, as well as various theme parks, ensure an additional transfer of valuable knowledge.

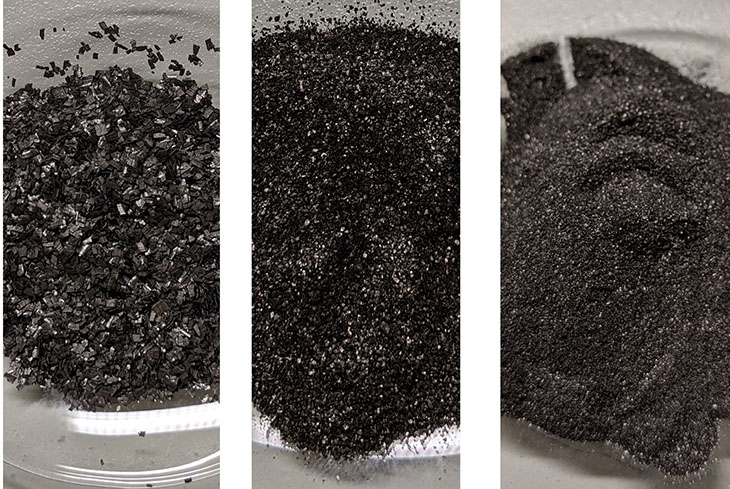

A rechargeable battery bursts into flames, customers complain about poor quality parts or a leaky component leads to recourse claims – the examples of damage resulting from burrs are numerous, and in any case they’re always expensive and detrimental to the affected company’s image. Despite this enormous impact on product quality, function and safety, deburring is a frequently underestimated step in the manufacturing process ... even though requirements for burr-free, clean components with high-quality surface finishes continue to increase in growth-oriented industry sectors such as components manufacturing for battery and fuel cell-based electromobility, hydraulics, sensor and analysis technology, the semiconductor supplier sector, medical and pharmaceuticals technology, as well as electronics and systems and machinery manufacturing. At the same time, disruptive developments are challenging parts manufacturers to gain a foothold in new market segments. However, success can only be ensured by means of further development and the adaptation of existing expertise and processes. Deburring, edge rounding, cleaning and the production of precision surface finishes definitely play a decisive role in this regard. In order to position themselves competitively for the future, numerous companies are seeking appropriate partners and solutions.

A Trade Fair for all Industry Sectors, Materials and Tasks DeburringEXPO, organised by private trade fair promoters fairXperts GmbH & Co. KG, provides an internationally unique communication and procurement platform to this end. It covers the entire spectrum of technologies, processes, tools and services for deburring, cleaning and surface finishing – across all industries and materials. “Its comprehensive range of offerings makes DeburringEXPO the ideal marketplace where users can search in a targeted fashion for solution-oriented partners for changing and new tasks in deburring and the production of precision surface finishes,” explains Gitta Steinmann, project manager at fairXperts. “44% of the visitors in 2021 came to the trade fair in order to prepare or finalise investment decisions.” Due to the great significance of DeburringEXPO for the operational procurement process, it’s also no surprise that all of the sector’s market and technology leaders have already made firm bookings for booth floor space at the upcoming event, which will take place at the Karlsruhe Exhibition Centre from the 10th through the 12th of October, 2023. “Demand for booth floor space from companies in Germany and from abroad has increased considerably since the end of February,” adds Gitta Steinmann. These companies also include businesses and startups who will be presenting processes to the public which have been developed in collaboration with research institutes and universities.

Supplementary Programme with Issues of Relevance for Competition The supplementary programme at this year’s DeburringEXPO will also be ideally adapted to increasing demands placed on quality, reproducibility and efficiency in production, as well as to changing production technologies. For example, the “Automated Deburring” theme park will demonstrate options for automated polishing, grinding and deburring of components with robots. Automation is also a possible solution for dealing with the shortage of qualified personnel. Whether before or after deburring, technical cleanliness in accordance with the specified requirements is an essential prerequisite for the quality of downstream processes, and thus for high-quality components as well. Corresponding methods and processes will be presented in the “Cleaning After Deburring” theme park. To an ever greater extent, specifications for deburring, edge rounding and surface finishing are being defined more and more precisely, for example rounding in the µm range and clear-cut specifications for roughness values. In-process or subsequent quality control is required in order to exclude possible defects. The “Quality Assurance in the Deburring Process” theme park provides an overview of the various measuring methods, as well as their strengths and limitations.

Knowledge Transfer as Added Value

The integrated 3-day expert forum is an established supplement to the exhibition programme at DeburringEXPO. Solutions for actual applications, as well as current developments, trends and future strategies will be at the centre of attention at the simultaneously interpreted presentations (German <> English).

Further information, the entire exhibition programme and a preliminary exhibitor list are available at:

www.deburring-expo.de.