The ltalmetal company with its headquarters in Jelcz-Laskowice specializes in the production of a wide range of elements made of sheets and strips in the field of embossing, punching and bending on presses. The list of the company’s clients includes such giants as Whirlpool, Hitachi, Electrolux and Miele. Italmetal is a family company whose constant feature is continuous development, implemented through investments in the production process, machinery and employees.

The Italmetal company started its operations in 2004 with only a crew of four and a 4,000 m² plant located in the Wałbrzych Special Economic Zone. When production was launched, the company’s technical resources included two 420-ton presses and several smaller machines. The team started out by producing parts for one customer. It was necessary to build a network of suppliers to implement the company’s development plan step by step. It was based on the experience in the automotive sector, brought by Aleksandra Adaszewska, managing director, and in-depth knowledge of the home appliances market, which was brought to Jelcz by the founder of Italmetal, Attilio Girardini. This marriage of know-how from two sectors, supported by the constant will to develop, still provides solid ground in gaining new customers, producing products of the highest quality and exporting them not only to the European market, but also to Turkey and China. Over the last 15 years, one of the indicators of Italmetal’s success have become two production facilities with modern machinery, recently transformed into one large factory and a warehouse with an area of 7,000 m2, which will soon be expanded by another 5,500 m2 of new part. However, square meters are not only a picture of the company’s constantly increasing production capacity, but also a daily workspace for over 260 employees from different countries.

- We gave up two locations to combine all production forces at Zachodnia Street. For this purpose, we are building another hall with an area of 13,000 m2. We plan to complete the works in the second half of 2021. Italmetal will then have an area of over 40,000 m2. As part of the expansion, we focus not only on the area of production and tool rooms, but also on improving the storage conditions for products, the facilities of the quality and maintenance departments as well as social rooms, cloakrooms and canteens. We also invest in new machines, thanks to which we will be able to better adapt to the needs of customers in the automotive sector. Our new acquisition is an impressive press with a pressure of 2 thousand. T. - says Attilio Girardini.

Factory 4.0 and a recipe for the future

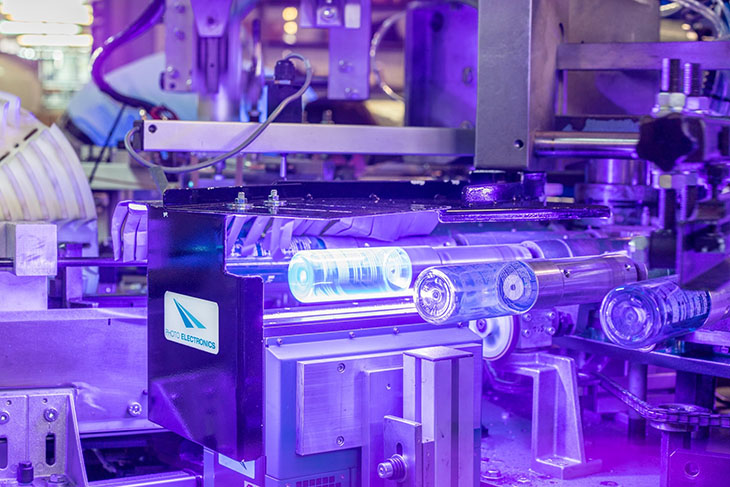

Consistent development and process automation have become a must for any company wishing to remain competitive in the industry. Thanks to the support of funds from the Intelligent Development program, Italmetal has created a new R&D Center with a laboratory and a prototype shop, with an area of 1,000 m2. Part of the project is cooperation with scientists in the fields of metallurgy, automation and image recognition.

- We are working on a system for creating dies and molds, we test new, more durable materials and methods of their processing, working on the most modern machines and researching alternative solutions using automation and computer vision. We implement innovative tools such as vision cameras that support employees in quality control and robots that cooperate with the employee, which can respond to human commands, learn and adapt to the environment. They are useful, for example, when packaging products. - says Lenon Dias Barth, head of R&D Italmetal.

The company, together with scientists from the University of Silesia, also implements a research grant whose main goal is to build a laser 3D printer. The machine will be used in the future to build tools, create elements from soft materials, and significantly reduce production costs. Italmetal, thanks to close cooperation with plants offering welding services, powder and cataphore coating as well as galvanizing, provides parts ready for assembly. The strategic potential of the company and the key to success is certainly the constant need for development and looking to the future, and then planning the strategy. The quality of the services offered is confirmed by numerous certifications, ranging from IATF 16949, which is extremely important for the industry, through ISO 9001, ISO 14001, OHSAS 18001, and ending with the business award from 2008, i.e. the prestigious Business Gazelles.

- We are dynamic and responsive, we see how the industry is developing and we respond to the future needs of customers. Our products are indispensable in industry. Steel and aluminum are used wherever high strength, lightness and profitability are important. Our perspective is the development of stamping, tool construction, gaining new orders, which will allow us among others, further production automation that we will introduce. In addition to the household appliances industry, we focus on the automotive industry. Electromobility is a good development direction. The demand for new elements is rapidly arising, for which we are already preparing our offer. We do not rest on our laurels, and we constantly invest to be better in terms of production, customer service and R&D. - concludes Attilio Girardini.

Networking and social responsibility

In Italian culture, partnerships are the key to success. Business doesn’t exist without them, and the human factor cannot be overestimated also in industry. Italmetal invests heavily in technology, but also enables development of a team of loyal and trained employees. Despite the pandemic crisis, no Italmetal staff member was dismissed. Moreover, the company has started new recruitments. Most of the specialists have been working here for years, and their promotion path is associated with in-depth knowledge of the company and progressing through the stages of development.

- We have a very open personnel policy, because in the end we care about innovation, and this is only created by the clash of different points of view. As a result, we work with experts from many countries with diverse experience. - says Attilio Girardini.

Similar rules apply to partner companies with whom long-term and friendly relations are a priority. Italmetal’s key suppliers are service centers delivering steel in coils or forms, both from Poland and other EU countries. Subcontractors include galvanizing plants, paint shops, plants dealing with vibro-abrasive processing, laser cutting. Transport companies are also partners, allowing for the implementation of timely deliveries to customers’ plants both in Poland and abroad, also outside the European Union. A special relationship based on daily joint work connects the company with the RBB Stal service center from Jarocin and Gonvarri Polska from Września. Italmetal pays attention to communication with the staff. Every year, the Family Day integration event is organized, to which employees and their families are invited. The company also publishes a newsletter in which it informs about the latest news. We are also actively involved in helping children in need in Poland (Oława) and abroad (Cameroon). Maintains friendly relations locally, among others with Jelcz - Laskowice, for which we received a medal for merits for the city. The priority of the development of a modern company should not only be the desire to develop production and increase revenues.

- We live in a specific environment and I believe that you should see the needs of others and build relationships. - emphasizes Attilio Girardini.