With more than 50 years of activity in the production and printing of flexible packaging - the Simplast S.r.l. is a partner of the most valued national and international companies in the food and non-food sectors. Head office and production site are located in the municipality of Civitella del Tronto, in the hamlet of S. Reparata, and cover a total area of 30,000 square metres. The continuous search for innovation in materials – sustainable and recyclable packaging solutions in particular, the development and implementation of high definition prints, the constant product quality control, as well as a timely commercial and technical service offered to partners – these are the principles on which Simplast bases and focuses its efforts.

Especially for Manufacturing Journal magazine, an extensive interview about the Simplast S.r.l. company was given by Mr. Dario Perazzone – Sales and Export Manager.

Could you briefly present the history of Simplast S.r.l.?

The company was founded in 1967 by the Di Serafino brothers, who started extruding PVC/PE profiles on a small scale. The first step towards the expansion of their business took place in 1970, with the introduction of the pipe division, mainly used for land irrigation. The contraction of the agricultural sector and the progressive expansion of flexible packs in the world of industrial packaging have required a redefinition of industrial strategies. In 1975, the first of a series of polyethylene film extrusion lines was introduced. Advertising and large-scale distribution mark the times in the varied world of packaging: the need to customise packaging became increasingly pressing. Simplast took up this new market challenge and installed the first flexographic printing plant in the new premises of Civitella del Tronto (TE). A new contribution to the development of the company came in 1990, with the implementation of the new lamination and cutting division: the production cycle thus integrated was completed, providing customers with the most innovative and safe packaging solutions. In order to respond to a growing demand and to offer its customers further production technology, in 2008, the printing department was further implemented with the positioning of an 8-colour rotogravure printing line. The aspect that I believe is important is that the growth of the company took place in a relatively long time, step by step. This has meant that all the knowledge and experiences lived in the field have created a very specific know-how that today represents a fundamental asset of the company that allows us to have the specific knowledge to implement the research and development of new packaging solutions to offer to our customers. What should be emphasised - to this day, the Di Serafino family is the owner of all the company’s assets and manages it.

What elements make your company unique compared to other companies operating in a similar industry?

Certainly, our production capabilities and the high quality standard of our products are the features that distinguish us in the panorama of European processors. Despite significant production capacity, we are a very efficient company that minimises waste. The management is active on a daily basis in all processes and takes great care to maintain a high level of productivity. We have a team of specialists who develop packaging solutions tailored to customers’ requirements and provide technical and design assistance. The constant collaboration with the largest producers of international raw materials allows Simplast to propose alternatives to commodities while maintaining a balance in the price of the product.

Could you tell us more about the production facilities? Does Simplast fit into the Industry 4.0 trend and invest in the latest technologies and solutions?

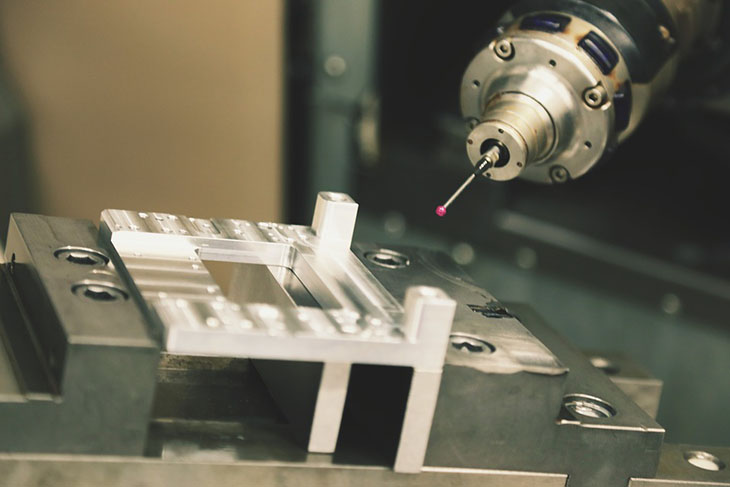

Production is divided into departments: polyethylene film extrusion, flexographic and rotogravure printing, lamination, winding and cutting. The printing technologies we use to produce our products are rotogravure and flexography. All our printing lines are of the latest generation, equipped with sophisticated control systems that, in addition to guaranteeing absolute quality and precision, allow us to produce at high printing speeds and with short stops for job changes. We have solventless couplers that allow us, with the use of specific glues, to combine materials of different nature. Our slitter allows us to slit monofilm or laminates even in very narrow strips and rewind the individual reels to the required length in order to optimise their use on packaging machines. Our extruders can film polyethylene starting from a thickness of 15 microns, allowing adding additives in order to give it the desired mechanical, slipperiness and welding properties.

What have been the new products and technological advances introduced by your Research and Development department in the last period?

We are developing materials from recycled granules and developing coupled homopolymers of the latest generation that can guarantee high barrier performance and mechanical properties. The use of eco-sustainable, compostable and recycled paper-based materials has certainly been the products on which our development and research department has recently focused.

Quality is a priority for Simplast. Your company works with selected, reputable suppliers and partners. Would you like to distinguish any companies - the most important partners?

All our suppliers are strategic partners for us. We believe that the mutual exchange of knowledge and common objectives leads to the achievement of optimal conditions for guaranteeing the highest quality. Each specific investment we make is discussed with our partners who, with their specific knowledge of specific critical issues, help us design the machinery and systems to be built. I don’t want to make a list of our closest partners and I just say that we evaluate new collaborations on a daily basis, but we strongly protect existing relationships.

What, in your opinion, are the main reasons for the company’s success? What strategies have proved to be the most useful over time?

As mentioned, I consider the experience and development gained in the right time to be very important. Even the technological investments of our production plants and their modernization have been planned with a specific logic aimed at the result of the product and its quality and not from a need for financial investment. Often too fast a company’s growth leads to skill gaps due to lack of experience. These gaps manifest themselves in a product that is not competitive both qualitatively and economically. Having the total knowledge of the product offered has always been our huge advantage. The Simplast has always supervised so that a tested product that is safe to apply on the packaging lines of our customers comes out of our production lines. Our company has always tried to establish a long-term collaboration with customers by investing in the quality of the relationship and aiming for a fair profit. We always seek complete customer satisfaction and by looking through the list of our current partners, we see that they are all partners with whom we have been collaborating for a long time in some cases, even for more than 30 years. This means that the overall consideration that our customers have towards us is always very high. We know that we have won it with a daily commitment and a proactive attitude.

How have the markets and customers changed in recent years?

Marketing strategies have led to a continuous change in the types of packaging materials to be used. Customers are looking for fast delivery with competitive prices and standard product quality. They are looking for a partner who continually suggests and proposes solutions aimed at increasing the productivity of their packaging lines and new printing and marketing solutions. Our research and development department plays a fundamental role in this. Clearly also the commercial conditions, in an increasingly competitive market, must meet the customer’s needs. Our financial stability also conveys a peace of mind that customers can count on for a peaceful future.

To which countries do you export your products? Who are your most important customers? What is the company’s annual turnover?

Our main markets are in Italy and generally in Europe, Africa and the Middle East. We collaborate with the largest producers of frozen products and baked goods. We consider all our customers as a fundamental part of our group. The annual turnover is around EUR 50 million.

Are you planning to expand into new markets and new directions?

We strongly believe in some emerging African markets and want to increase our market share in Northern Europe.

What are the current market trends affecting your company?

The world of packaging has correctly taken a path that leads to minimising the environmental impact of packaging. The markets are looking for increasingly high-performance materials and require a reduction in quantity in the overall volume of plastic used. We are involved in this process and are focused on finding eco-friendly alternatives to offer to our customers. Environmental protection is our priority and a fundamental basis of our concept of sustainability.

What were the most important investments related to the development of Simplast in recent years?

We have updated the flexographic printing department with a new production line that entered into operation in December 2020. A new complex solvent recovery system came into operation this year guaranteeing a reuse of 100 tons / month of solvent with a consequent drastic decrease of emissions. The sales network was also strengthened with the opening of a new office in Northern Europe.

What are the company’s current plans?

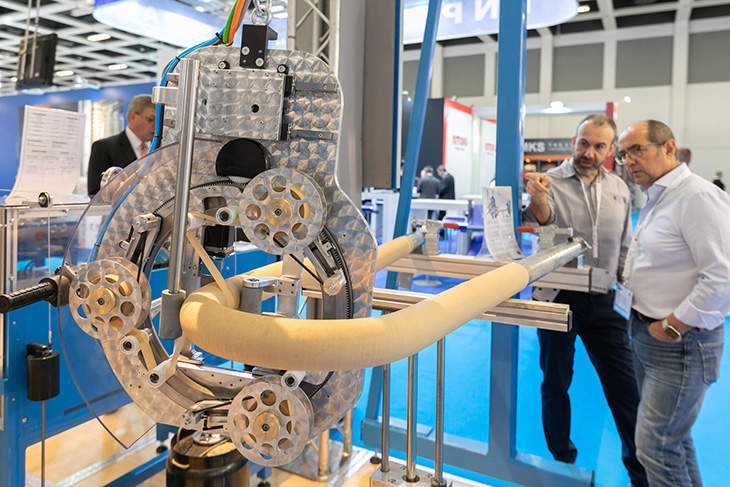

Unfortunately, we are going through a very sad and complex geopolitical moment where the availability of raw materials is in absolute emergency. In addition to the situation in Ukraine, the covid-19 pandemic has undermined development plans that will inevitably have to be revised. At the moment we focus on maintaining our market position primarily in order to ensure regular supplies to our customers. We continue to be present at international trade fairs and keep an attention on the various markets but as mentioned, we focus our efforts on the markets in which we have already been present for some time.

How do you see the prospects of your company over a period of five to ten years?

Simplast has a farsighted owner who has always managed the company in a transparent and determined way. In our sector, due to this very critical historical moment we are going through, we will see many companies forced to review their positions or even forced to close their businesses due to lack of financial or market resources. I believe I can state that thanks to continuous investments and timely management of resources, Simplast will maintain its role as a reliable, innovative player in the near future and will further increase its presence and competitiveness on the markets where it currently operates.