SCHULER SUPPLIES FULLY AUTOMATED AND TURNKEY PRODUCTION LINE COMPLETELY

FROM A SINGLE SOURCE

Waghäusel, 26.08.2013 – Schuler SMG displayed the latest developments

in hydraulic press technology at an in-house show held in Waghäusel in

mid-July. Just under 100 visitors from Germany and abroad were able to

see two drawing presses for automated manufacture of high-precision

gearbox components, as well as a universal press for manual production

of various parts. The highpoint of the in-house show, during which

various technical papers were also presented, involved a presentation of

a fully automated production line for the famous German chainsaw

manufacturer, Stihl.

"Schuler is supplying the entire machine itself," explains CEO Dr.

Martin Habert: "From the coil line to the blanking and stamping press,

through to the automatic unstacking station." The line, about 25 meters

in length, is intended for Stihl Incorporated in the US town of Virginia

Beach. It will be used for making the blades of chainsaws from highly

heat-treated tool steel in various sizes and lengths – referred to in

the business as chainsaw bars. They are composed of right and left-hand

outside parts, an inside part as well as what is referred to as the

sprocket that transports the chain with the saw teeth.

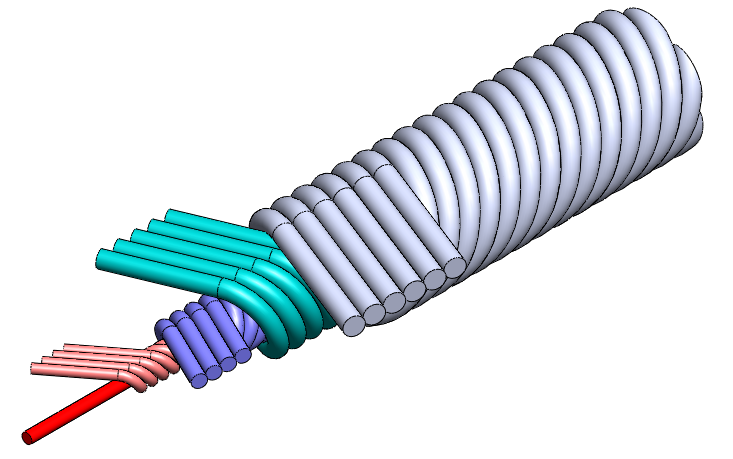

But what actually happens inside the machine? The process starts with

the twin-headed decoiler where the sheet is unreeled from the coil and

then passes through the leveling machine and the roll feed. In the next

step, it is stamped out by a hydraulic 500-tonne press type SH

500-1.2x0.8. The slide force then cuts the bar. The remaining sheet

metal passes through the chopper and finally ends up in the scrap waste

container.

14 MONTHS FROM RECEIPT OF ORDER TO DELIVERY

However, the parts still have further travel ahead of them: the next

station is a hydraulic 250-tonne stamping press (SH 250-1.2x0.8) which

gives the chainsaw bar its final shape. Finally, a marking press punches

in the batch number before a linear portal with a double gripper stacks

the parts. This enables a magazine change to be performed during

production. As a result, interventions in the system are possible

without any interruptions in production.

Only 14 months elapsed between the receipt of the order and the planned

delivery at the end of August: "This is a result of close and efficient

cooperation between Design, Production and Project Management," says CEO

Dr. Martin Habert. However, Schuler will remain a point of contact for

Stihl even after commissioning, which is planned for early November: The

press manufacturer's US subsidiary based in Canton, Michigan, will also

look after the machine's service requirements.