Precision Micro, the U.K-based photo-etching specialist, has signed off on the purchase of a new 4 chamber etch machine. The machine represents the first in a series of investments that the company believes will help maintain its position as Europe’s leading supplier of precision etched components.

The new machine — built to Precision Micro’s specification — comes with comprehensive data logging functionality allowing for full machine control, and energy monitors that optimise supply assisting in Precision Micro’s continued focus on environmentally conscious manufacturing.

Commercial Director Mick Taylor says: “As Precision Micro continues to reinforce its reputation as a class-leading manufacturer, it is vital that it continues to use best-in-class technology solutions at every stage of the manufacturing cycle.”

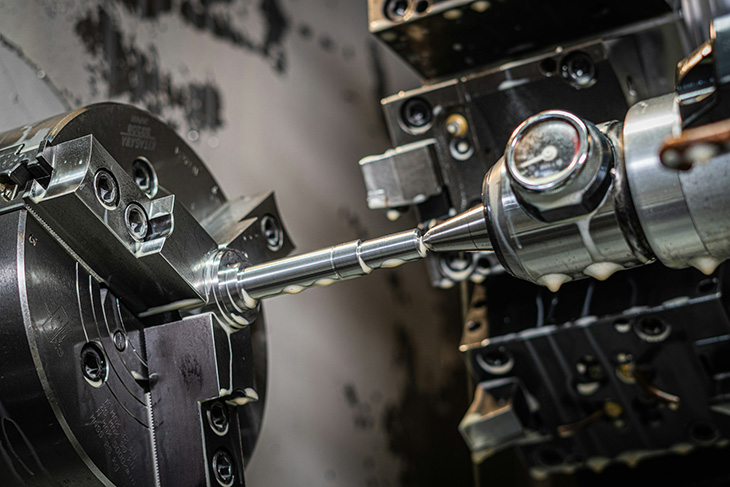

For over 50 years, Precision Micro has pioneered photo-etching, a manufacturing technology using subtractive chemical erosion to produce burr- and stress-free precision metal components. The company has won a reputation as the industry innovator, trusted to deliver by major global manufacturing concerns across multiple industry sectors.

Business Director Marcus Heather explains the place etching has in industry today. “Photo-etching is precisely suited to applications where the requirement is for small, precise, complex, feature-rich parts with no burrs, and no stress-related changes in the metal, which can occur using alternative metal forming technologies”.

“Traditional processes tend to struggle when applied to the working of thin metals, stamping and punching being inappropriate in many instances, and laser and water cutting causing disproportionate and unacceptable degrees of heat distortion and material shredding respectively.”

“The new machine will enable Precision Micro to produce larger volumes, making it even more competitive with stamping, and to work with thicker materials. In addition, it will allow for enhanced process control than the machine it is replacing, which in turn will provide for increased reliability and enable a wider offering of etched components for the company’s customers”.

The machine will be delivered and installed in the first quarter of 2015.