Cooperation and business development with AMAC

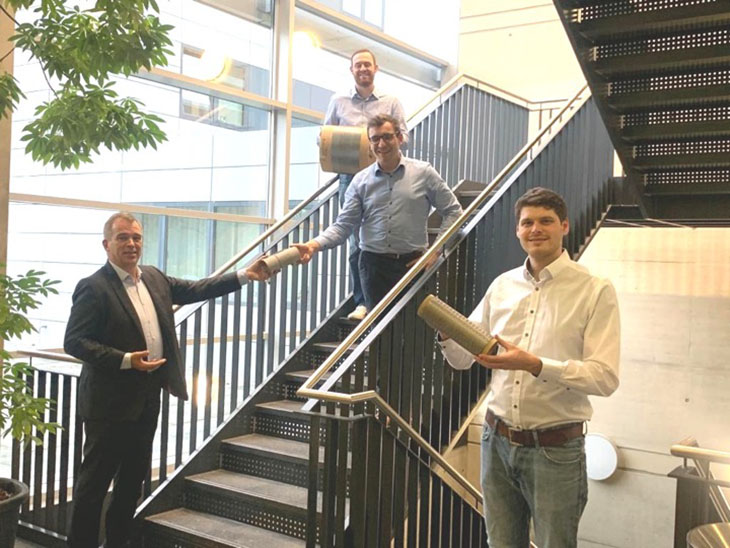

As of November 1st, 2020, AMAC is pleased to announce its cooperation with company FibreCoat for the market introduction of their products and global business development. FibreCoat is a young, award-winning start-up and spin-off of the RWTH Aachen University in Germany and develops multi-filament coated yarns, fabrics and composites based on glass or basalt fibres.

Dr. Michael Effing, CEO AMAC GmbH: „FibreCoat is a very promising newcomer in the electro-magnetic shielding and composites industry and their innovations are very cost-efficient for new technologies such as e-mobility or telecommunications. I am very pleased to introduce them to relevant key players in the industry and accompany them in their growth strategy.“

Award-winning technology

FibreCoat has already won several international awards: the recent and famous „Falling walls venture“ award for advanced materials in Berlin for the most-promising science start-ups from across the world for the production of their innovative thermoplastic coated glass fibres, which can be processed into composites for lightweight components and which significantly reduce the cost of composites, commonly used as alternatives for steel and aluminium. Furthermore, FibreCoat was awarded at the AC² Gründungswettbewerb for young entrepreneurs in Aachen, Germany and is finalist in the category Mobility at the Hello Tomorrow Global Challenge 2020 in Paris, to name just the most recent ones.

Product Launch

FibreCoat develops metal-coated fibres like bi-component multi-filament yarns with basalt core and aluminum coating which can be used for EMI-shielding and heat sinks in battery casings, electric diverters in filters, reinforcement of cast aluminum parts o ras conductive yarns in smart textiles.

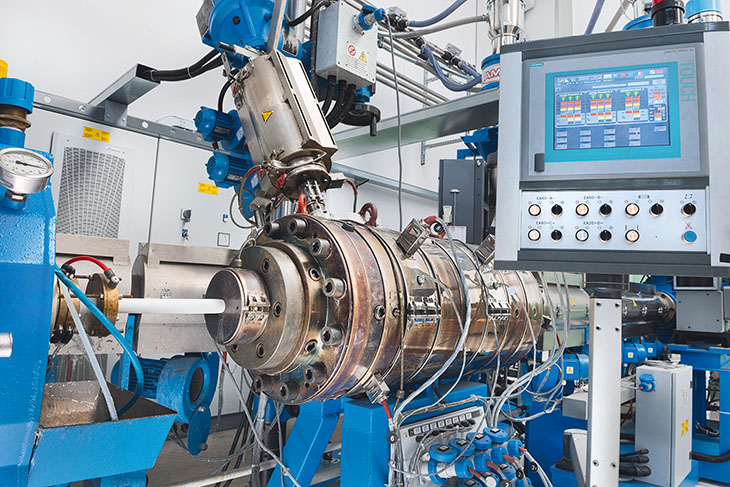

Today, FibreCoat launches ALUCOAT™, an aluminum-coated glass or basalt fibre which is suitable as electro-magnetic shielding material in automotive applications such as radar, antennas or for autonomous driving as well as for mobile phones and applications in buildings. Due to its extraordinary thermal conductivity and better heat transfer compared to traditional composite material, it can be used for the manufacturing of automotive battery trays or industrial applications such as fine particulate air filters.

ALUCOAT™ is available as of January 1st 2021 as a yarn, fabric or non-woven with a wide range of possible titers and areal weight. The material will offer an electrical conductivity of 100 Ωm and a working temperature of at least 400°C. Furthermore, it can be used for the shielding of low to high frequencies with an effectiveness of 80 to 120 dB.

Dr. Robert Brüll, CEO FibreCoat GmbH: “ALUCOAT™ is the first product on the market where each single filament is coated uniformly during the spinning process. Therefore, the product has superior properties, it outperforms in shielding and thermal conductivity and has a significantly lower price than any today´s incumbent products. Furthermore, we are working on a product consisting of multi-filament glass-fibre coated with polypropylene polymer to be launched at JEC 2021 which will be destined mainly for automotive and industrial applications.”