Manufacturer of fittings for high-voltage lines orders two screw and five C-frame presses for its plant in Austria

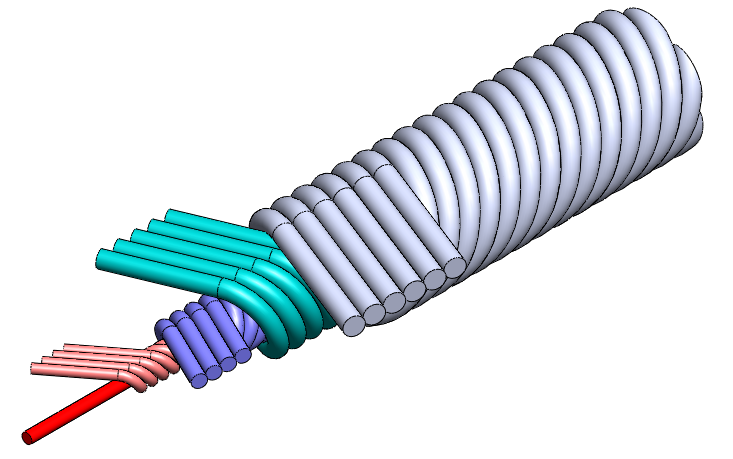

Göppingen/Weiz, July 27, 2021 – Mosdorfer GmbH, based in Weiz, Austria, can look back on more than 300 years of experience in forging. Starting in the middle of the last century, the company specialized in fittings for high-voltage overhead lines up to 1,200 kilovolts, which transport electricity around the world from the hottest deserts to the highest mountains. Two screw and five C-frame presses, which Mosdorfer has now ordered, will also be employed in the production.

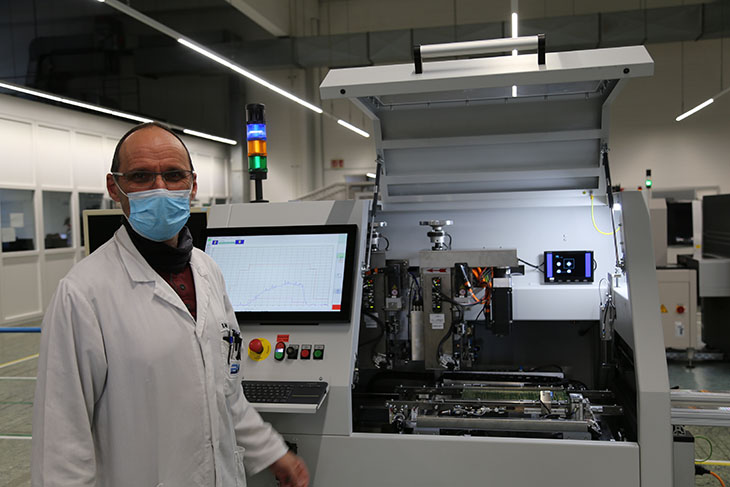

"For the first time, our customer has opted for lines from Schuler," Managing Director Frank Klingemann is happy to say. "Since particularly economical and energy-efficient machines are to be used in Mosdorfer's new forge, our screw presses with ServoDirect technology are the ideal solution." These are machines of the type PAR360 SDT as well as PAR265 SDT with 2,100 and 1,100 tons of press force.

Thanks to the servo motors, the screw presses have a lower design and offer improved drive controllability as well as higher starting torques with shortened stroke cycle times. The closed water cooling circuit for the servo motors results in optimized temperature stability of the drive system, independent of operational air conditions.