A robotic gripper allows a machine to handle a tool or product and manipulate it as required for the particular task. Holding, placing, tightening, and releasing are some of the actions a gripper can take.

Someone investigating robotic grippers may wonder whether they should get a pneumatic gripper vs. hydraulic gripper. These are not the only two options, but they’re among the most popular. Here’s a closer look at these two possibilities.

Pneumatic vs. Hydraulic Gripper Strength

How powerfully a gripper can grasp an item typically comes into someone’s decision about what kind to choose. However, in some cases, it’s more important that the gripper can hold a product securely without the risk of breaking it.

A more robust gripping strength is necessary when a robotic arm handles heavy loads. Hydraulic grippers are the best option when such power is a top concern for an application. They typically offer maximum high pressure ratings of about 750-2,000 pounds per square inch. That amount falls to approximately 150 pounds per square inch for a pneumatic gripper.

Pneumatic vs. Hydraulic Gripper Functionality Differences

Pneumatic and hydraulic grippers differ in how they work. A pneumatic gripper needs a compressed air supply. The air moves an internal piston, making the grippers open or close. These options have no motors or gears, which may make them appealing to people who worry about internal components breaking down through prolonged normal use.

Additionally, compressed air is a relatively easy resource for many people to get. Some facilities already have it on-site.

Hydraulic grippers move pistons with pressurized fluids. They also have internal pumps and reservoirs and need oil. This makes them more complicated to maintain than their pneumatic counterparts. Plus, there’s no risk of a pneumatic gripper leaking contents into a work cell.

Pneumatic vs. Hydraulic Gripper Applications

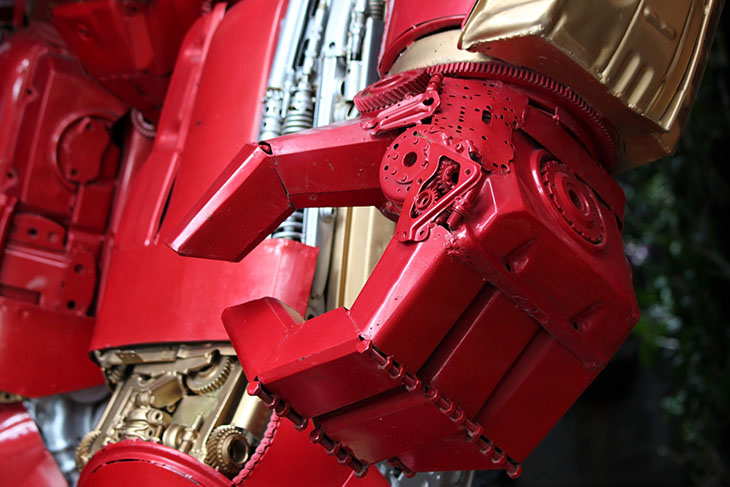

Pneumatic vs. hydraulic gripper discussions will also happen when people think about how they intend to use the machines containing the grippers. Some have two pieces that open and close like jaws, while others feature several components that work together similarly to human fingers.

Jaw-type pneumatic grippers are good solutions for handling small to medium-sized components, such as placing or installing them. However, hydraulic grippers are better when the pieces are substantially larger or heavier.

One car engine factory uses collaborative robots to assist with tightening screws on those products. However, if the task also required lifting the engines, the more powerful hydraulic grippers would be most appropriate.

Pneumatic vs. Hydraulic Gripper Implementation, Popularity and Maintenance Details

Pneumatic grippers are lighter and generally more compact than hydraulic ones. These characteristics tend to make them the more popular type of the two. Manufacturers can put them into tight spaces to use them in smaller areas of a factory without making significant layout changes first.

One statistic indicated that pneumatic grippers comprise 90% of the market. Someone interested in purchasing a gripper and wants a type that’s already widely used might therefore opt for a pneumatic type.

Many potential purchasers understandably want to see strong evidence that they’re likely to get good results by using a particular gripper. The marketplace popularity of pneumatic grippers could be a strong selling point for people who wish to see case studies from others in similar situations.

It’s also generally accepted that hydraulic grippers have more upkeep requirements than pneumatic ones. People interested in buying them should also consider whether their current maintenance teams understand hydraulic requirements or if they need to hire additional personnel. For example, hydraulic systems need fluid added to their reservoirs that’s cleaned first.

People may lubricate the air powering pneumatic systems depending on the application. However, that’s an increasingly less common practice.

Pneumatic vs. Hydraulic Gripper Cost and Control Concerns

Pneumatic grippers come out on top when people care about costs and control capabilities since they are less expensive than hydraulic ones. They also provide more control than hydraulic options.

These differences illustrate why people in the market for grippers should consider how much they want to spend on them. After that, they should think about whether their intended applications require a high degree of control.

Evaluating the Gripping Tool

Regardless of what a person chooses after going through the pneumatic vs. hydraulic gripper debate, they need to look at what happens when the component grabs something. They must assess the end-of-arm tool (EOAT).

The fragility of whatever the robot handles is a top concern. Having a robot grip a product such as a strawberry too hard could turn it into mush, making it unsellable. However, if there’s little or no risk of harming the item with the robot, people have more flexibility in how and when they use the grippers. No matter what kind of gripper a person chooses, it should provide options for changing the gripping strength to suit the product.

Another thing to consider is whether the product features a delicate surface that the gripper could damage through normal handling. The increasing popularity of using robot grippers in industries such as manufacturing has caused continual interest in improving them for various applications.

In one case, engineers at the University of Georgia took inspiration from pole bean plants to design a soft robotic gripper. Their creation can grasp items as small as 1 millimeter in diameter. The team designed the gripper to work with only a single pneumatic control. They said it only needs a small operating space, making it ideal for confined areas. The engineers also used silicone for the gripper’s outer material, which is unlikely to damage whatever it handles.

Pneumatic vs. Hydraulic Gripper: Which Is Best?

This breakdown shows there is no universally ideal option when people weigh the differences between pneumatic and hydraulic grippers. Their choice comes down to budget, intended use, and whether a person needs high gripping strength. People will be better positioned to make an informed decision after considering these aspects.