Getting a four-year degree is not the best fit for everyone’s circumstances and goals. Instead, they may be interested in the benefits of trade school. Such options can be more affordable and allow students to enter the workforce sooner. As more schools offer manufacturing training programs, how do trade and technical schools support the industry?

1. Improving Opportunities for Underserved Populations

The manufacturing industry offers a range of choices and possibilities for students from all backgrounds, especially those in marginalized groups. One example comes from Navajo Technical University, a former vocational school that is now home to one of the most advanced manufacturing schools in New Mexico. Many of its students are Native Americans who want to enter careers that allow them to stay close to home while boosting their earning potential.

The campus includes a 5,500-square-foot steel building that gives learners hands-on experience. They can interact with specialized equipment and analytical products. Teachers are committed to giving American Indian students the same chances to succeed as individuals with more resources. They also encourage students to follow their curiosity, simultaneously uncovering new abilities and interests.

Participating in manufacturing training programs offered at technical schools can broaden learners’ prospects while giving the industry access to well-qualified people who have in-demand skills and are ready to earn. These characteristics create mutually beneficial situations for everyone involved.

When manufacturers consciously try to find qualified people from marginalized groups or those not typically targeted for these roles, they actively create more diverse workforces. Additionally, the hired individuals bring valuable perspectives and life experiences beyond their workplace skills.

2. Increasing Industry Readiness

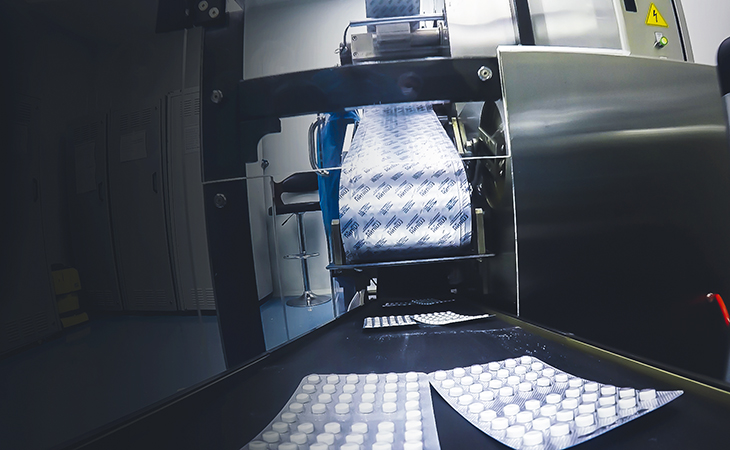

Many manufacturing leaders prefer hiring people who have the necessary skills and familiarity with specialized equipment. There is an increasing demand for operators who can use advanced machines. Technical schools provide those fundamental capabilities, helping students feel comfortable using equipment such as CNC machines in controlled, educational environments before employers eventually hire them. One of the benefits of a trade school is that it supports people who prefer hands-on learning.

While technical schools still include traditional learning elements like lectures and readings, students often spend more time on experiential activities that will serve them well in the workforce. Some programs include industry sponsorship, allowing students to learn the equipment and skills needed to work at specific companies.

One example comes from a tech company funding manufacturing training programs to support microchip production. Students can enroll in a two-semester initiative that sets them up to become entry-level technicians at the company. Alternatively, people can continue their studies to qualify for placement into more advanced roles.

This effort is part of a larger education drive to equip 9,000 people with the in-demand production skills needed in today’s economy. This creative approach allows the manufacturer to address a known need while offering participants appealing ways to grow their skills by embarking on a defined career path.

One of the benefits of trade schools is that they make education more accessible due to the increased affordability of many programs. Additionally, people are often more motivated to take that route when they know they’ll learn specific skills that prepare them for future rewarding careers.

3. Addressing Labor Needs

The manufacturing industry is grappling with a prolonged worker shortage exacerbated by numerous causes, including retirement and changing perceptions about prospects. Although there is no single way to fix this issue, some manufacturers have become proactive by expanding training opportunities. That makes sense since 68% of American workers are open to retraining to broaden their skills.

Although some students may primarily attend technical schools, others engage in hybrid approaches that involve splitting time between educational facilities and company premises. Many such options are also in learners’ communities, highlighting how they can get trained to work where they already live rather than needing to move elsewhere to support themselves. Company leaders benefit, too, by using education to create a skilled and available workforce.

When one aerospace manufacturer faced an above-average number of positions to fill at a specific factory, it launched an on-site training academy for people with basic welding skills. This addition facilitates training up to 48 fully qualified welders annually, depending on their experience when they enter the program. Those who need more skill development get paid to take classes at a nearby school while receiving an hourly wage.

It is common for companies to run manufacturing training programs by partnering with technical schools. However, this example shows many must get even more creative about recruiting people and preparing them for their roles.

Many people are eager to prepare for new careers if they know that work will lead to steady jobs. They also appreciate having well-defined pathways rather than trying to find the educational opportunities themselves and hoping for the best once they complete their programs. Involvement from specific manufacturers increases learners’ confidence that they are improving their prospects by participating.

The Benefits of Trade School Will Remain Relevant

These advantages emphasize why so many manufacturing training programs have trade school components. Whether learners go to locations to develop skills through hands-on facilities or spend part of their time on manufacturers’ sites while attending classes, these options are essential for creating and maintaining a skilled and well-equipped workforce. Will they factor into your career plans?