From now on, selecting the right metering and mixing system will be even easier for customers. METER MIX has restructured its product portfolio.

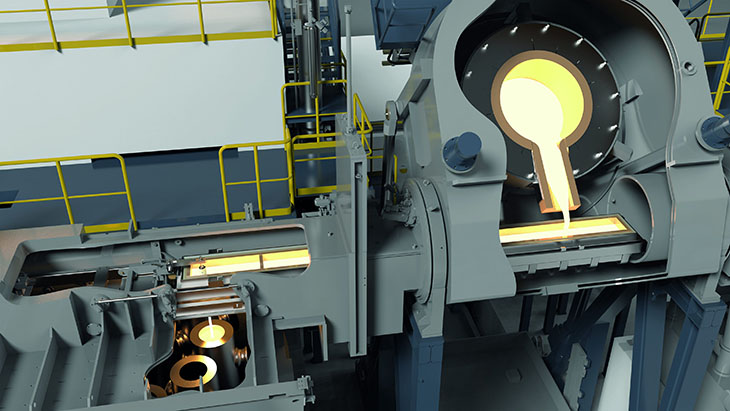

METER MIX SYSTEMS specialise in metering, mixing & dispensing solutions for industries in which the production process involves potting, bonding, sealing, RIM and many more. METER MIX machines are used to process two-component materials such as epoxies, polyurethanes and silicones with consistent reliably and repeatably. The systems have two defining characteristics: They are easy to handle with no detriment to high performance.

From now on, selecting the right metering and mixing system will be even easier for customers. METER MIX has restructured its product portfolio. Customers can now choose between two different material categories:

- Machines for processing liquids

- Machines for processing pastes

Within these two categories, they can then choose between two different technologies:

- Material dispensed by continuous flow

- Material dispensed by shot

The LiquidFlow and PasteFlow series utilise proven gear pump or progressive cavity pump technology. Further benefits are pulsation-free dispensing, variable mixing ratio and accurate flowrate control.

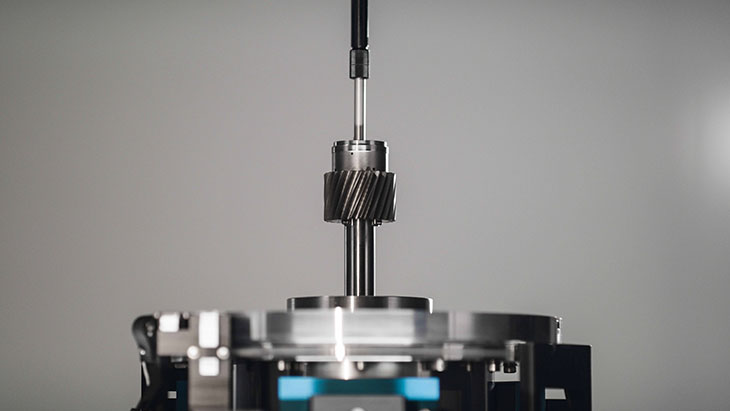

The LiquidShot and PasteShot series utilise piston pump technology which is proven for reliable and robust operation. A further benefit of this technology is the precisely achievable metered shot sizes.