Optimizing your condensate recovery system can save money, improve sustainability and increase system efficiency. Every boiler owner or operator should consider investing time and money to maximize the performance of this key part of boiler systems.

1. Save Money on Energy Bills

Optimizing your condensate recovery system can significantly reduce your energy consumption and expenses. This is due to the boiler’s reduced need to treat and heat raw make-up water. The water from the condensate recovery system is already distilled and heated. Utilizing it effectively saves energy by effectively reducing the workload of the boiler.

Consider the typical amount of energy a boiler requires just to produce steam. Depending on the type of fuel powering the boiler, it can get quite expensive.

Reducing the energy needs of your boiler system in any way possible can reduce the fuel required to produce steam, saving you money. Optimizing your condensate recovery system can be a great way to accomplish that. The U.S. Department of Energy even has a free steam system modeling tool you can use to view the potential fuel energy savings of different efficiency changes.

2. Reduce Environmental Impact

Reducing your carbon footprint is one benefit of reducing the energy your steam system consumes. Even small boilers can have a serious environmental impact. For instance, a typical gas-powered household boiler emits 2.2 metric tons of CO2 annually, equivalent to seven transatlantic flights.

Ideally, next-generation steam systems will use renewable energy. Electric boilers are showing promise but tend to be expensive and still require a clean energy source, such as solar. Truly emissions-free boilers are not yet a mainstream technology. So, the best way to reduce the environmental impact of steam systems is to reduce the fuel required to do their job.

Improving operational efficiency is a great way to accomplish this. The condensate recovery system is particularly ideal for sustainability goals because optimizing it can reduce water and energy consumption. It recycles water the boiler has already treated and heated, allowing it to be reused. Maximizing this process's efficiency minimizes the energy required to heat raw make-up water, minimizing emissions by extension.

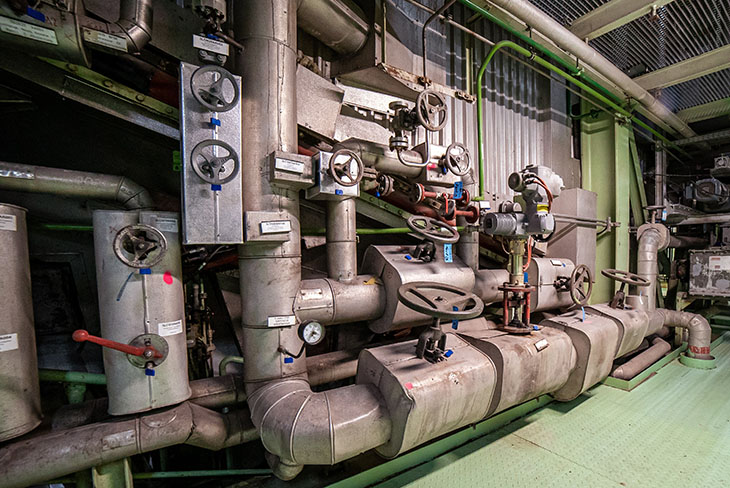

3. Improve Boiler Efficiency

A well-optimized condensate recovery system can be a valuable contributor to the overall operational efficiency of any boiler. Not only does it reduce water and energy consumption, but it also increases throughput.

Water from the condensate recovery system can be considered pre-heated, pre-treated feedwater, ready to go when it returns to the boiler room. It does not need to go back through the water treatment and heating process but can be used immediately. As a result, the condensate recovery system can effectively increase the steam a boiler can produce in a given period.

Keep in mind, though, that boiler efficiency requires a whole-system approach. Every component contributes, for better or worse.

Updating underperforming boiler components can augment the benefits of condensate recovery system optimization for even greater efficiency gains. Various free tools are available online for identifying the right condensate return pump to support top condensate recovery system performance.

4. Reduce Water Consumption

Optimizing your condensate recovery system is a great way to reduce the raw make-up water your boiler consumes. Excessive water consumption is not only expensive but bad for the environment. Luckily, the condensate recovery system is specifically designed to recycle water.

Maximizing condensate recovery reduces the amount of raw make-up water that needs treatment, reducing the amount of treatment chemicals required. In fact, using more recovered condensate water can improve the overall quality of your system’s feedwater and allow you to reduce blowdown water loss.

Of course, some amount of blowdown is necessary in any boiler system. However, utilizing condensate water can help minimize blowdown needs, reducing water and energy losses. Even reducing blowdown by 2% can save tens of thousands of dollars per year, according to a 2012 study.

Recovered condensate water helps accomplish this by reducing the amount of impurities in the feedwater. By the time condensate water is recovered, it is distilled and typically contains little to no dissolved solids. It does not contribute to the contamination blowdown is used to remove, reducing the need for blowdown. As a result, condensate minimizes blowdown-related energy and water losses by providing clean, reused water to the feedwater system.

5. Prevent Maintenance Issues

Finally, optimizing your condensate recovery system helps prevent expensive, time-consuming maintenance issues. Like any other piece of equipment, boilers are prone to breakdowns without proper fine tuning. For boilers specifically, interior corrosion can be a big concern.

The condensate recovery system can help with this issue. It reduces the overall oxygen level in the feedwater system, minimizing the likelihood of corrosion. A well-optimized condensate recovery system can prevent corrosion while improving your boiler’s performance.

The condensate recovery system also supports other parts of the water treatment and heating process. For example, pre-heated water from recovered condensate reduces the need to heat raw make-up water, reducing strain on your boiler’s heating system. Over the long term, small improvements like this can strengthen the boiler's life span.

Optimizing the Condensate Recovery System for Success

With a little fine-tuning, the condensate recovery system can transform your boiler’s performance. It can increase efficiency, improve sustainability, and reduce water and energy consumption. These benefits create a high return on investment.