Globally, solar energy has become the largest type of energy for newly installed electricity generation capacity. Lately, solar energy has accounted for about two-thirds of all new power generation installed globally. Solar energy can be scaled quickly and thus lead the global green transition.

An important milestone was the COP28 climate meeting in Dubai when the world decided to "move away” from fossil fuels and that all countries must limit warming to 1.5 degrees. This requires "deep, rapid and lasting reductions" in greenhouse gas emissions and large investments in renewable electricity production are required.

Carrots and sticks

There are strong trends for solar energy globally. The playing fields are littered with carrots and sticks – attractive subsidies on the one end and punitive regulation on the other. And in the middle: an investment that makes sound financial sense.

25 percent of the EU’s energy can in the long run come from the sun. The Union also wishes to break the dependence on imported solar panels mainly from China and build a domestic industry for the production of solar cells.

The EU's Recovery and Resilience Facility of more than 670 billion euros has been available for investments that make the member states’ economies and societies more sustainable, resilient and prepared for the green transition. The EU Innovation Fund financially supports innovative net-zero technologies for climate neutrality.

Transformative proposal for rooftops

The most transformative proposal is the "the EU Solar Standard" which European Parliament legislators adopted earlier this year. The new law contains guidelines for the installation of solar cells on public buildings and residences in the EU: solar cell installations must be included in new building projects, and public buildings may retroactively have to install solar cells.

It comes into effect gradually with new public buildings in 2026, commercial and public buildings being renovated in 2027, new residential buildings in 2029 and existing public buildings in 2030.

This makes perfect sense since there are billions of roofs all over the world that can be covered with solar panels. Clean electricity can be harvested where it is consumed and need not even strain the grid. The technology is proven and relatively cheap. Installation is easy.

Larger industrial and commercial roofs are especially advantageous due to the larger size that often makes installation easier and more profitable. But there is a serious hurdle: Up to half of existing roofs in Europe cannot handle the weight from traditional silicon panels. They are not constructed with these types of loads in mind; one single silicon panel can weigh 35 kilograms, framed and mounted with ballast. The weight of silicon panels on a 750 sqm industrial roof could be in excess of 15 tons. The roofs are simply not built for that.

So, a property owner that is compelled to install solar panels onto the roof faces an expensive roof reinforcement or replacement job before panels can be laid.

Thin film solar cells the sole choice for weaker roofs

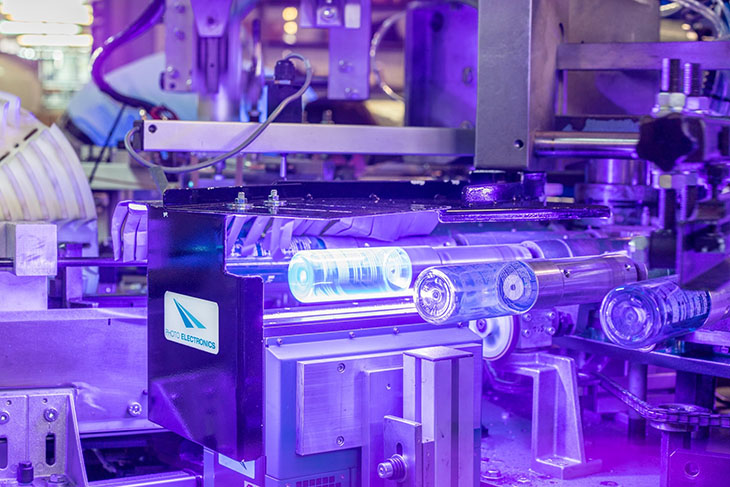

An easier, cheaper and more environmentally friendly option would be thin film solar panels. They are not made of brittle silicon and do not need to be protected by glass, nor be framed or even mounted (they are simply “glued” on). They are very thin, flexible, durable and most importantly in this case: very light making them ideal for larger low-load-bearing roofs.

The production process is completely different compared to silicon solar cells, so the climate footprint measured over a life cycle is only a fraction (1/10) of traditional solar panels. This is a factor that is rapidly becoming very important with property owners and lessees.

Other keen buyers are property owners with higher aesthetic ambitions who do not want to change the architecture of the property – thin film solar panels are visually much less intrusive and, in some cases, virtually invisible.

Thin film solar panels can expand the fast-growing triple billion-dollar solar rooftop market greatly, maybe doubling it, and create a protected market for suppliers that can offer light-weight solar solutions for low load-bearing roofs.

The question is from where this big anticipated rise in demand will be met. European solar photovoltaic production capacity is decreasing, under pressure from cheap dumped silicon panels from mainly China.

European supply is shrinking

Several European producers of silicon panels have been forced to shut down as the price per watt for a silicon panel has halved on the European market. Today, China accounts for approximately 98 percent of all global wafer production. This monopoly position is problematic, such as the fact that approximately 45 percent of the silicon is produced in the province of Xinjiang, where ethnic Uyghurs are systematically forced to work in the factories under slave-like conditions.

Many markets do not accept solar panels manufactured under these conditions. The U.S. implemented the Uyghur Force Labor Prevention Act (UFLPA) in late 2022. It bans the import of products made in whole or in part with forced labor in Xinjiang. India too has imposed import restrictions and tariffs on Chinese panels.

But since Europe has neither customs duties nor laws against the import of these panels, the shipments are redirected to Europe where it is sold at record low prices. The freedom from customs duties and the price dumping means that the majority of European manufacturers of solar cells, which have to pay customs duties on imported input materials, have been forced to scale back, relocate or shut down production.

Thin film for weaker roofs a game-changer

Until these anomalies are rectified, European manufacturers of solar cells must work with their present advantages, which include traceability in the supply chains, higher quality products, and a significantly lower carbon footprint from the point of view of the product's life cycle.

The trump card can be the ability to develop and market thin film solar cells for the large number of industrial roofs on the continent and worldwide that cannot withstand the weight of silicon panels. This is the industry's and the market's big game-changer in the coming years.

Eric Jaremalm, CEO, Midsummer

Eric Jaremalm is co-founder and CEO of Midsummer, a leading Swedish manufacturer of thin film solar cells. He has over 25 years of experience from international business and development of high-tech production equipment. Prior to founding Midsummer, he worked with Micronic Japan KK as head of research and development cooperation with Japanese semiconductor manufacturers and as project manager for installation and production start of equipment for semiconductor manufacturing in Japan. Mr. Jaremalm holds an MSc in Industrial Economics from the Linköping University of Technology. Eric also studied at the Meiji University in Tokyo and the Nanzan University in Nagoya and speaks Japanese. See http://www.midsummer.se/.