Biogas is a renewable energy source produced through the anaerobic decomposition of organic matter. This gas can be used for electricity generation using turbines or power plants, as well as for heating through systems such as furnaces, boilers, and stoves that operate with gas combustion. It mainly consists of methane (CH4) and carbon dioxide (CO2), but can also contain contaminants like sulfur. During its production, sulfur present in the organic matter is converted into hydrogen sulfide (H2S), a corrosive, toxic, and environmentally harmful gas.

To address this issue, a process known as desulfurization is used, aiming to reduce or eliminate sulfur compounds, such as H2S and sulfur dioxide, from liquids and gases. This process is essential for improving the quality of biogas and avoiding environmental and technical issues.

Sulfur is a natural element found in many organic and inorganic materials, and its release can have negative effects both technically and environmentally. Therefore, desulfurization is crucial for enhancing the quality and performance of sulfur-containing products.

Various desulfurization methods exist, classified into chemical, biological, and physical methods. Each has its own advantages and disadvantages, depending on the type of product, the desired level of desulfurization, and the operating conditions.

Desulfurization Methods

Chemical Methods

These methods use chemical compounds to transform H2S into non-corrosive substances. Common agents include ferric salts, such as ferric chloride (FeCl3) or iron sulfate (FeSO3), and oxygen (O2). These agents react with H2S, forming a solid precipitate that can be separated from the biogas. While chemical methods are efficient and fast, they can have drawbacks like high energy consumption and the generation of solid waste.

Biological Methods

Biological methods utilize microorganisms that decompose H2S. The most common microorganisms are sulfate-reducing bacteria and anaerobic fermentative bacteria. These microorganisms use H2S as an energy source, oxidizing it into sulfate (SO4) or elemental sulfur (S). Biological desulfurization systems can be autotrophic, where microorganisms use CO2 to produce elemental sulfur, or heterotrophic, using organic compounds to produce sulfate. These methods are cost-effective and environmentally friendly, but their reaction speed is slower, and they are sensitive to variations in pH and temperature.

Physical Methods

Physical methods involve processes such as absorption and adsorption to remove H2S from biogas. In absorption, the biogas is passed through a liquid that has a high affinity for H2S, such as water, alkaline solutions, or organic solutions. The H2S dissolves in the liquid and is separated from the biogas. The liquid can be regenerated through thermal or chemical treatment. In adsorption, biogas is passed through a solid material, like activated carbon or zeolite, which retains H2S on its surface. These methods are versatile, but challenges like pressure loss and saturation of the absorbent material can arise.

A Promising Solution for the Future

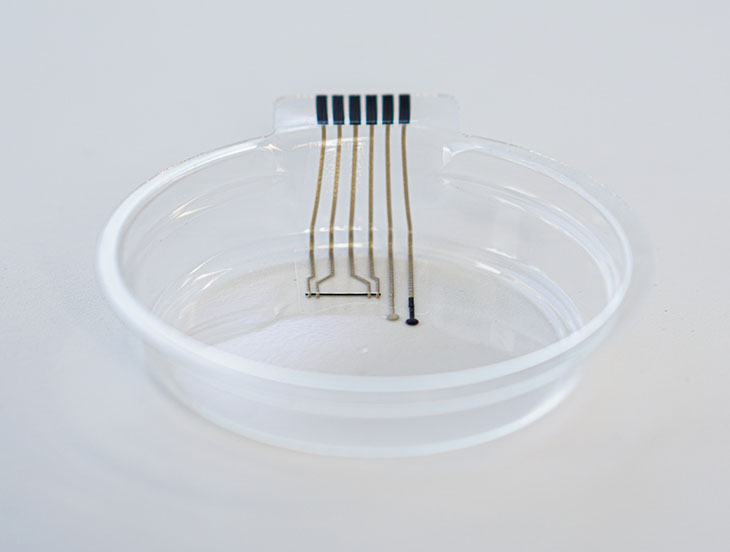

Biogas desulfurization using bioreactors is an innovative approach that has gained traction in the energy industry. This method offers various benefits, including cost reduction, simplified design, improved efficiency, and minimized waste generation. Bioreactors allow for the optimization of factors such as pH, temperature, and hydraulic retention time to enhance the desulfurization process. Different types of bioreactors can be used, including fixed-bed, fluidized-bed, membrane, or biofilm reactors, each suited to specific substrates and desulfurization needs.

Benefits of Desulfurization

Reduction of Corrosion

Removing H2S from biogas helps protect biogas plant equipment, extending its lifespan. H2S is corrosive and can damage pipelines and other components. When it reacts with oxygen and water, it can form sulfuric acid, which is even more corrosive. Desulfurization reduces these risks, minimizing maintenance needs and improving facility safety.

Improvement in Biogas Quality

Removing H2S increases the calorific value of biogas, meaning more energy can be obtained from each unit of volume. It also helps prevent unpleasant odors and health risks. In cases where biogas is upgraded to biomethane for injection into the gas grid, it is crucial to comply with strict regulations regarding H2S concentration, which in some countries is limited to 10 ppm. This ensures the protection of the natural gas and biomethane transportation systems against corrosion.

This comprehensive approach to biogas desulfurization is key to producing cleaner, more sustainable energy, reducing environmental impact, and enhancing the viability of this renewable resource.