General Motors, one of the world’s largest automakers, has been a synonym for excellence in the automotive industry since it was founded in 1916.

Every year the concern sells millions of cars and trucks globally under such brands as Buick, Cadillac, Chevrolet, GMC, GM Daewoo, Holden, HUMMER, Opel, Pontiac, Saturn, Vauxhall and Wuling. With global headquarters in Detroit, General Motors has its manufacturing operations in 34 countries, including a Polish factory in Gliwice (General Motors Manufacturing Poland). Specializing in the Opel cars production, it is one of the most modern plants of General Motors in the world.

Beginnings of General Motors in Poland

The history of General Motors Poland dates back to 31 May 1991, when the company was registered and started importing the Opel cars to the country. Owing to the political transformation, which entailed the beginning of free market economy, and the lack of competition at that time the Polish market seemed potentially attractive to foreign investors. From the initial stages of its activity General Motors Poland developed rapidly – as soon as in 1992 it already had 25 and retail outlets and 14 authorised service station. Currently, the sales network of Opel in Poland consists of 68 main dealer stations and 29 satellite points. When it comes to the service, the number of service centers grew to 72 main and 27 satellite ones. The business activity of General Motors Poland revolves around import, after-sale service as well as production of the Opel brand.

Production activity

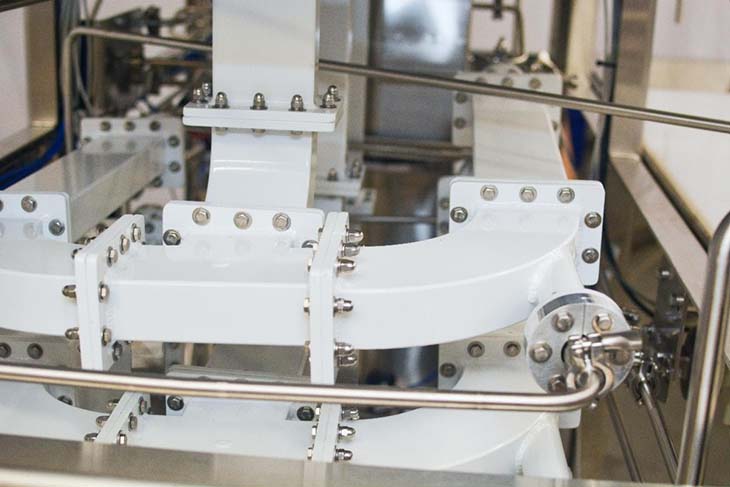

The production activity at General Motors Poland started in 1994 with assembling Opel Astra in Warsaw, followed by the Vectra model four years later. The Warsaw assembly plant ceased to exist by June 2000 after the plant in Gliwice became the main GM production centre in Poland. General Motors invested about EUR 700 million in General Motors Manufacturing Poland (formerly known as Opel Polska). Having been built in only 22 months, the cutting-edge assembly plant in Gliwice was opened in 1998 and immediately started production of Astra Classic, which was the first model manufactured at the site. In 2000 the Gliwice factory, as the only GM plant in the world, launched the assembly of the Opel Agila. Nowadays GMMP produces three Opel models: Zafira (the 7-passenger compact MPV vehicle), Astra III NB and, from November 2009, Astra IV.

The investment which has paid off

The plant in Gliwice is the largest foreign investment in the Katowice Special Economic Zone. Employing approximately 3000 people, the plant gave a boost to the region and had a positive impact on the industry. Within the last years, the exports amounted to 82% of the production, which constituted around 1,4% of the domestic exports in 2008. It can be easily noticed that General Motors has made a significant contribution to the development of the Polish economy. Apart from the export revenues, the concern has been actively promoting Poland, recommending it as an investor-friendly country. Moreover, intensive cooperation with Polish suppliers has contributed to the significant growth in their number. They supply products and services not only to GMMP in Gliwice, but also to other GM units around the world, which makes it possible to create additional workplaces. In 2004 the daily Gazeta Prawna awarded GM the prize for the best foreign investment in Poland within 15 years from 1989 to 2004.

The ISO policy

The success of the investment in the Gliwice plant lies in a variety of factors. The most important ones are modern methods of management and production, highly qualified staff, top quality of products and concern for the environment. The quality of products has been certified by comprehensive reports, which included the opinions of customers from top European markets. Moreover, in 1999 the plant received the certificate in accordance with the ISO PN-ISO 9002 norm, which was granted by two independent certifying institutions – KBA (Kraftfahrt Bundesamt) from Dresden and PCBC (Polskie Centrum Badań i Certyfikacji – Polish Centre for Testing & Certification) from Warsaw. Controls carried out later in time confirmed the factory’s compliance with all the requirements of the norm. Since the overriding aim of GMMP is to produce cars of prime quality with a view to the protection of the environment, the management of the plant decided to implement the Integrated Quality Management System (ISO 9001:2000) and Environmental Management System (ISO 14001), for which the certificates were granted in 2002. Based on the guidelines included in the norms, the factory compiled “The Integrated Management System Policy”, which contains its commitments referring to the quality of goods and protection of the natural environment. According to the policy, the company strives to be the world-class factory, devoted to improving products and services, taking care of the employees’ safety as well as their professional development and making use of innovative technologies. When it comes to reducing the negative impact on the environment, the plant uses eco-friendly solutions, e.g. in a paint shop, which was designed and built in accordance with stringent EU standards. Car bodies are covered with an innovative lead-free, anticorrosive paint, while all priming paints and surface coats are made in the water dilution technology, which entails no harmful emissions of fumes from organic solvents. Owing to state-of-the-art varnishing robots, as well as the presence of a sewage-treatment plant on site, the plant reduces the amount of waste material to the minimum.

Non-business activity achievements

The activity of General Motors in Poland also consists in its commitment to social and charity undertakings. To give an example, GM was involved in building „Houses of Hope” – the project realized in cooperation with an international organization Habitat for Humanity. Another initiative was directed towards young people – 18,000 have paid educational visits in the plant so far. Among other programs there was one called Plato, aimed at small and middle companies from the Silesia region. GM also organized a jubilee concert for the inhabitants of Gliwice and the nearby area. Success achieved by General Motors Poland as well as General Motors Manufacturing Poland was attested by various institutions, which rewarded the companies with prestigious titles and distinctions. Among them there are: the title “Investor of 1999 for GM Poland and Opel Polska”, granted by Polski Klub Biznesu, the awards of the General Motors’ President (1999, 2000, 2001, 2003 and 2004), the distinction „For the Renovator of the Polish Industry” („Dla Tego, który Zmienia Polski Przemysł”) by The Association of Enterprise Support (Towarzystwo Wspierania Przedsiębiorczości) (2000), “The Economic Prize of the President of Poland” (“Nagroda Gospodarcza Prezydenta RP”) in the category “Best Foreign Investments in Poland in 2000” (2001) or the title “Benefactor of the Year 2001” (“Dobroczyńca Roku 2001”) by Academy for the Development of Philanthropy in Poland (Akademia Rozwoju Filantropii w Polsce) (2002). Having been granted the “Employer of the Year” titles for several times, GMMP was also widely recognized as a reliable employer in the Katowice Special Economic Zone and in the whole of Poland. When it comes to products which leave the assembly line at GMMP, Opel Astra IV deserves particular attention. It won the awards „Golden Wheel” (“Złota Kierownica”) in a poll organized by the Auto Świat magazine (2009), as well as ”The Best Cars in 2009” („Najlepsze Samochody roku 2009”) (2010) and the “Auto Leader 2009” (2010) by the Auto Motor i Sport magazine.

Written by Anna Chudzik