This is the success story of the Italian manufacturing company that continues to set a great example for others and proves that through dedication, hard work and a customer- oriented mindset any small business can expand and become successful.

The beginnings

Founded in 1963 in the Food Valley, FBR-ELPO is a manufacturer of machines and complete lines for fruit and tomato processing in aseptic filling. It has been a leader on the international market for over 50 years and that says a lot. In the beginning it was a small company manufacturing machines for the food industry on specific requests, but then it quickly gained the trust of its customers both in Italy and abroad and earned a well-deserved position on the market, equal to that of the biggest companies of the sector. After the acquisition in the early ‘90s of ELPO, a leading company in the construction of machines for the aseptic filling, it has taken the current name of FBR-ELPO and since then it has started to strengthen its market position. The filling aseptic machines are the pride of the company and are considered as a high quality product all over the world. FBR-ELPO is now able to provide a full range of solutions for the processing of tomato, fruit (even tropical) and for filling in aseptic conditions, starting from single machines up to turnkey complete lines. The main reasons for the success of the company are tailor-made products that meet the specific customers’ needs both in terms of the production capacity and the end product they want to receive.

Projects and production

One of the crucial things in running the business in a successful manner is to invest in the research and development area. FBR-ELPO invests in a team of engineers and experts dedicated to the research and development of new technologies and technical solutions. The research centre is responsible for the design of the machines and implementation of new IT systems to apply to new installations as well as existing ones in order to optimize them. The technical and technological solutions studied and adopted have significantly contributed to the improvement of the production systems, the reduction of energy consumption, efficiency, and profitability of production lines.

Trusted business partners

When talking about the driving factor of the successful company, the quality is the answer and to maintain once gained customers’ trust, it is imperative to work with the trusted partners. Throughout the years FBR-ELPO have established a very good partnership with companies like Siemens, Allen Bradley, Eaton and ABB. They all act as the direct provider of the electronic components. The list does not end here and to name a few more we have Endress Hauser Italia (flow meters), Gea (piston pumps, Niro Soavi aseptic valves), Spirax Sarco (sanitary valves, steam and heat exchangers), Interpump (piston pumps), Pieralisi (decanter), Gardner Denver (circulation pumps, high temperature water and CIP), Bardiani (aseptic valves), Spx Flow Technology (aseptic valves), Festo (pneumatic pistons and electronic Islands), Smc Italia (eletronic islands).

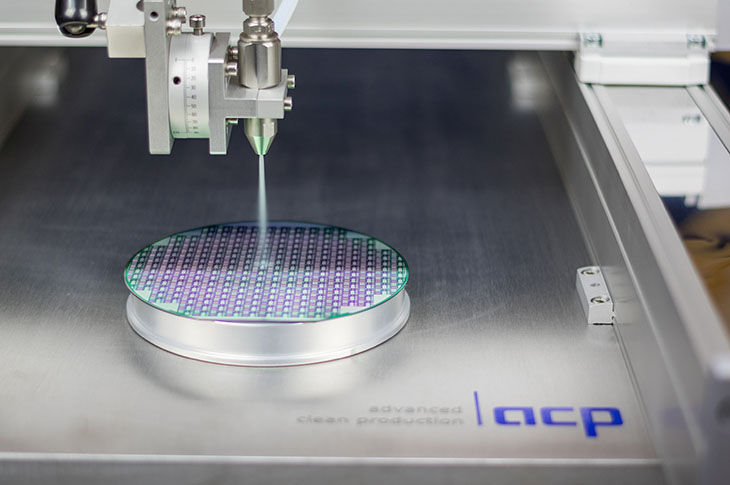

Quality control

FBR ELPO prides itself on being of the best quality and those are not just words. To back this up, the company has been ISO 9000 certified for over 10 years now. Recently it has been certified ISO 9000-2015. Quality control is conducted in acceptance of the quality department through the verification of the correspondence between DDT, order and material. It is followed by the integrity of the packaging check and the existence of documents/certificates and its correspondence. Finally, controls on material is conducted: via a visual analysis or dimensional checks that are made with special instruments, the correspondence between specifications in design and measured values.

Strategic markets

The target market is spread worldwide. It is mainly concentrated in Europe, Africa, Centre and North America. It is no surprise that the main customers are multinational organisations from the dairy and the food & beverages sector. The long-term plan is to improve the company’s position in Eastern Europe but also in the countries of the former Soviet Union. Somebody could ask why the customers keep choosing FBR ELPO over all the other companies with the similar business profile. The reasoning behind it is staying flexible, customer-oriented and maintaining the highest technological standards.

The team

FBR ELPO consists of a team of over 80 employees, of whom about 30 are strictly production workers. It looks like a lot, but each year more than 80 production orders are processed therefore the numerous staff is crucial.

R&D field

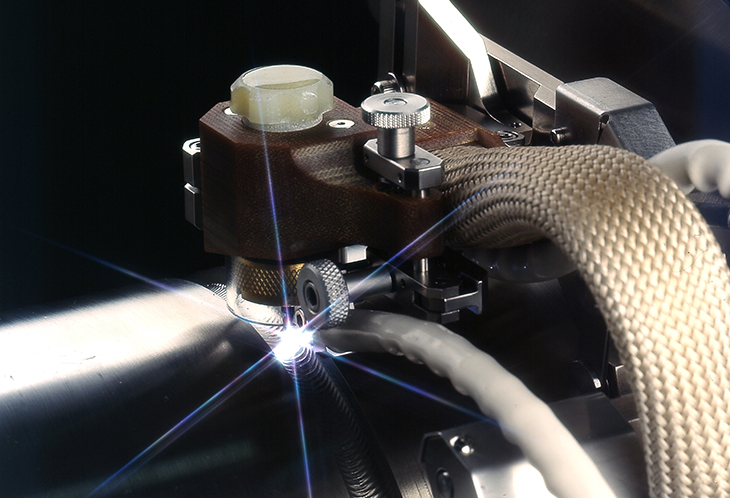

In the last period many new ideas and technologies have been introduced in the research and development area. The team has designed and manufactured a new version of the sterilizer based on the radio frequency system called “ELETTRA”. It is an ideal solution to improve and optimize the treatment of fragile products for colour and sensory characteristics, as well as for processing products with pieces. When using the radio frequency system of sterilization, the product does not get heated from the outside (does not get exposed to the heat of the water). Instead, it is heated directly from the inside, ensuring numerous advantages including the reduction of working time and maintaining of the characteristics of the product. As opposed to the traditional methods, the radio frequency technology can also be applied to defreezing of products in pieces to be allocated to further processing, ensuring the consistency and the structure of the processed raw material to prevent any kind of damage.

Technological innovation

Any recent improvements made in the technological innovation area? The answer is yes. FBR ELPO has developed a new operating system to maintain the control of all the ongoing operations called INTUITIV RELATIONSHIP INDUSTRIAL SUPERVISION (IRIS). It allows to monitor the entire production process by live analysis of the processed data. Every machine is equipped with the wide database and live video diagnosis as well as the archive of the past actions. All the software and hardware developed by FBR ELPO are in line with the Industry 4.0.

What the future holds

The company recognizes two main areas they want to focus on and invest in. Those are human resources and technological innovation programs. That is the only way to make further significant improvements in the quality of the offered products and the only way forward. Of course – as any company – the 5-10-year plan is needed. Clear goals need to be set and the most crucial one for FBR ELPO is to keep being present on the market by constant upgrade of products and services. What is more, the company is ready to anticipate customers’ needs.

FBR ELPO today

Despite the company’s great success there are no plans to slow down. The manufacturer consistently maintains the high level of growth and hopes to keep this trend in the future. Worth mentioning is also the fact that recently the company has renewed their trademark. It is now the perfect representation of the balance between the broad experience of FBR in food processing and the continuing trend towards innovation of ELPO in aseptic filling. To sum up, new competitors will surely appear on the market, but FBR ELPO is definitely the name to know and to remember.