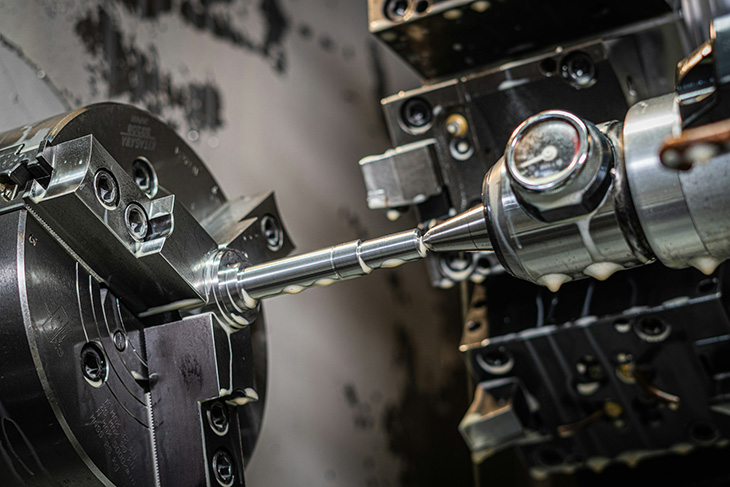

An industrial robot is designed to take over a process or task to improve efficiency, performance and uptime. The idea is to speed up production, deliver quality output and automate that particular area of the operation. Like all modern systems, an industrial robot requires proper care to remain in good condition, which waylays potential downtime and malfunctions — under the right treatment plan.

However, the problem with traditional maintenance strategies is that they are reactive. They tend to call for an assessment, fix or action after a breakdown has occurred. A much better and more beneficial form of care is preventive maintenance, which takes a proactive approach to problems.

Preventive, Predictive and Beyond

In a preventive care plan, maintenance crews will monitor, identify and replace components or problematic systems before they cause a failure. It also includes basic maintenance, such as topping up fluids, checking valves or seals, cleaning and polishing surfaces, and much more. Conducting routine checks ensures the equipment is in tip-top shape, avoiding major outages.

It’s important to point out that preventive care is meant to be used alongside normal operations. Industrial robots and equipment are not powered down unless they need to be or there’s a safety issue.

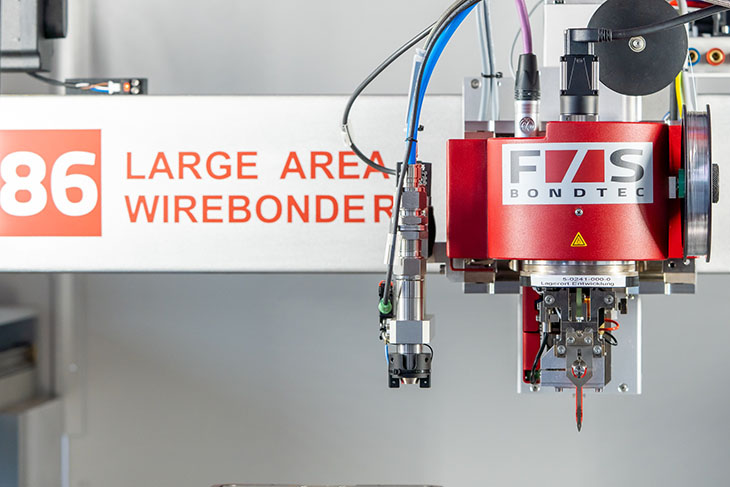

An excellent solution that augments preventive maintenance programs is predictive care. It employs the help of automated monitoring solutions, including AI, to deliver real-time alerts about potential issues. More importantly, the system analyzes performance trends, working conditions, component quality, and various factors to provide an estimated report about general performance and operation.

Operators can use these insights to detect and diagnose problems that may be coming down the pipeline — all delivered through real-time and contextual data. It’s a reactive form of care, but the equipment is assessed far in advance, well before problems start affecting the machinery.

The Many Benefits of Preventive Maintenance for Industrial Robots

Failure to deliver regular or basic maintenance can be a catalyst for malfunctions, causing increased wear and tear on machinery, or worse. Proper preventive care, administered to head off problems, provides a host of benefits beyond standard care. Those include:

- Significantly minimized downtime

- Faster marketing, production or manufacturing times

- Enhanced product quality and output

- A reduction in energy and resource consumption

- Extended equipment or industrial robot life spans

- Improved worker and vendor safety

- Lower operating costs due to higher performance and longer-lasting equipment

What Issues May Arise?

You may experience some issues with industrial robots without preventive care. These include:

- Position or parameter deviation where the equipment doesn’t work as intended, isn’t accurate or potentially damages goods

- Decreased performance and automation

- Cable and component damage due to increased friction and wear

- Control software breakdowns because of various malfunctions

- Safety concerns including injuries to workers, operators and passerby

Worse yet, malfunctioning equipment can affect other industrial robots, machines and processes nearby. It can create a ripple effect where the entire operation needs to shut down until the problem can be alleviated.

When to Schedule Care

A care plan template should be used for an entire warehouse or facility of equipment, while each piece of gear should have its own maintenance schedule. For example, some leading industrial robots shouldn’t need frequent care, so scheduling preventive checks every 10-12 months is fine, especially when combined with predictive monitoring systems.

Maintenance crews should take the time to reference manufacturer and equipment recommendations to find the preferred maintenance schedule. Equipment that’s operational 24/7 may need to be cared for more frequently.

This is an area where predictive maintenance solutions provide excellent support. IoT, smart data sensors, and other information-driven technologies will feed the necessary stats into a core system, relying on machine learning or AI to extract relevant insights and automate the entire process. Those insights, usually delivered through digital reports, inform future action.

Maintenance teams can see if a particular piece of equipment is experiencing deteriorated performance. They can also find other conditional problems, like operating temperatures beyond the norm or even fluid leaks.

Hydraulic swivels are commonly used when a constant transmission of fluid power is needed, without cross-contamination or leakage. Monitoring the performance of such components — even when they are designed to withstand a wide range of temperatures and pressure ratings — can provide insight.

What Preventive Maintenance Looks Like

An extensive preventive care plan is often called for and can look more complex than traditional strategies, but it’s well worth the investment and effort. Here’s how a general preventive maintenance system might work:

- Develop a strict upkeep schedule for each industrial robot or piece of equipment.

- Implement the plan and ensure the entire maintenance team understands their responsibilities.

- Deploy predictive technologies or solutions to monitor the equipment in between daily, monthly and annual checkups.

- Regularly assess the plan and equipment inventory, replacing failing systems or components long before a problem occurs.

- Use the ingested data and insights to create an effective reporting system that either alerts on-site maintenance teams or sends a call out to experts, vendors and third parties.

- As the maintenance program is leveraged, continue to make adjustments to improve accuracy and efficiency.

Beef up Employee and Worker Training

Alongside a proper preventive care plan is the need to educate the maintenance team and all workers and operators that will be in direct contact with the industrial robots and machinery. Establishing a proper training regimen, for maintenance technicians especially, should always be a priority. It will need to be rolled out alongside, or in advance of, preventive programs.

Online and digital course tools are available to help educate and build awareness, or you can enlist the help of equipment vendors and experienced professionals. All workers should be informed, not just the maintenance personnel, because everyone can help move the care plan along by pointing out potential issues, defects, and other signs that point to the need for repairs or replacement. The more eyes you have on the equipment, the better off your team will be at spotting incoming events.

It might also call for a proper ticketing or timeline system so crews can request repairs, service checks and maintenance tasks.

Don’t Forget the Basics

Preventive care isn’t just about avoiding problems that are coming down the line. It’s also about keeping equipment in tip-top shape, with high performance ratings. That means basic care is just as important.

Brakes, components, rails and other moving parts should be inspected and assessed. Fluids should be topped up, seals replaced and external bolts tightened. All robotics and machinery must be visually inspected for grease, oil or fluid leaks, and they should also be cleaned consistently. Controller cables, cable connections, power suppliers and other electrical systems should be checked, inspected and measured.

Vents and cooling systems should be cleaned, with dust effectively removed and filters swapped out. Batteries should be replaced regularly.

All these tasks can be added and implemented as part of the preventive care plan, with maintenance teams ready to administer support. With the proper program in place, industrial robots can continue operating to their full potential for a long time.

Author: Emily Newton