The Vitillo Group was established in 1991. Thanks to the enterprise and passion of the Vitillo family, the Vitillo company is now a leader in the hydraulics market.

Especially for Manufacturing Journal, an exclusive interview about Vitillo Group was given by Mr. Antonio Vitillo - CEO.

Could you briefly describe the history of the Vitillo Group and most important moments of its development?

Our company was born by the dream of the family’s progenitor, Mr. Vitillo Giuseppe. We really started from zero, with a couple of machineries placed in a garage. Ambitions weren’t lacking, but difficulties were a lot too. Luckily, with a lot of work and thanks to the ability of seizing the chances that arose over the years, we have expanded our business more and more, up to reach what we are today. In the first decade of working we concentrated ourselves on the production of fittings and adaptors, increasing over and over the range of offered products. Year 2003 represented a turning point in our history because we decided to start the production for braided and spiral hydraulic hoses too. Since this choice has been made, since the idea of offering to customers even more products, but above all of taking care directly of each production phase, our success was born. Clearly, we cannot allow ourselves the luxury of stopping. As our motto goes: „We feel better under pressure”.

Please tell us what made your company so successful and gained the trust of its customers?

I think what is mainly appreciated by our customers is that we focus on the aim of simplifying their life. What we propose to the market is an „integrated project”; this means a full package of products related to hydraulic circuits. Many are the companies that offer products similar to ours, but few are those that have such a complete range. Our customer finds in Vitillo everything he needs, not only in terms of products, but in the sense of a continuous technical end engineering support also.

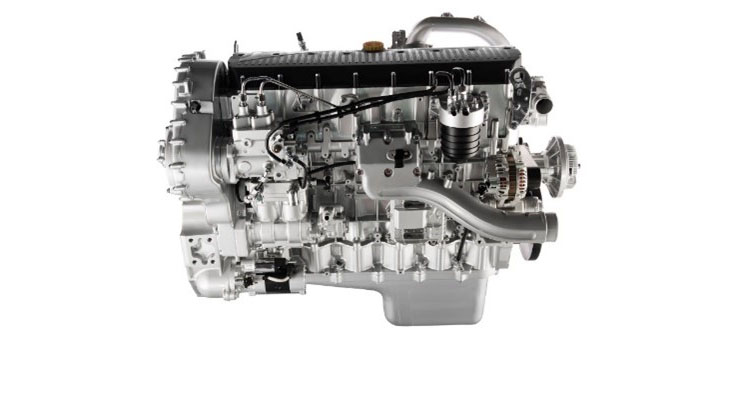

Your ability to accommodate your customers’ unique requests enables Vitillo to offer a complete solution to each of your customers. Solutions include production and distribution of fittings, adapters, rigid or flexible hose for high and medium pressure fluids. Can you tell us more about your products, services, used technologies and production facilities?

As previously mentioned, one of our strength points is flexibility in responding to different market requests and coping with both peak demand and requests for customized or small batches productions. In order to do this, we have equipped ourselves with a wide diversified machineries fleet that includes CNC; multi spindles machineries and transfer machineries for big production batches. Furthermore, we have specific plants dedicated to galvanic treatments (Chrome III and zinc-nickel), two production plants for hoses and one entire factory intended for the production of rubber compounds for hydraulic hoses.

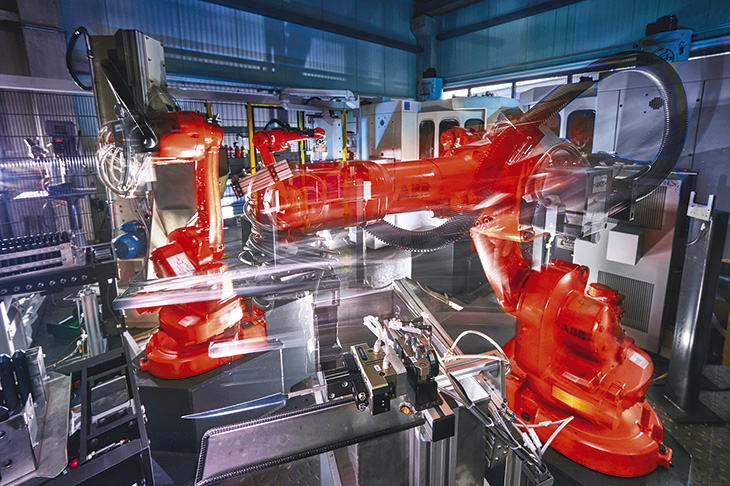

Worldwide industry boldly focuses on robotics and automation of production processes. Does the Vitillo S.p.A. is also part of a trend of 4.0 Industry and invests in the latest technology?

Yes, of course, ours is a company that each year invests a significant part of its turnover. We are constantly evolving and this “revolution” of the industry 4.0 has affected all of our factories, thanks to smart fiscal incentive policies implemented by Italian Government also.

Which strategies have proven to be the most useful over time?

For what our experience is, the vertical integration of production activities! This strategy allowed us to be competitive, extremely flexible in production and above all, to have the full control of products’ quality at every stage of the value chain.

Please tell us about your company’s quality control system.

The company is ISO 9001:2015 certified for Quality Management Systems. This means that a series of processes that guarantee a continuous screening for all activities of value chain is effectively implemented (from supplying up to finished products). Furthermore, we have the certifications ISO 14001 for Environmental Management Systems and ISO 45001 for Occupational Safety. All of this reflects in efficient business processes, respectful both of environment and workers and, ultimately, in products of the highest quality.

What certificates your company owns?

Impartial third-party accreditation institutions test and verify that Vitillo’s hoses and fittings are compatible with specific requirements of the various application fields, those institutions certify the high quality of our products. In particular, the main certifications that we own are:

- MARINE TYPE APPROVALS (GL, DNV, RINA)

- MINING TYPE APPROVALS (MSHA, JSH)

- RAIL TYPE APPROVALS (LAPI)

- SPECIAL TYPE APPROVALS (GOST-R)

Please tell us about the size of your production and the number of people you employ in your company.

Currently the Group counts approximately 400 employees, 8 production plants, 4 distribution Centers all over the world (USA, Germany, Poland, Italy) and 1 research and development cutting-edge laboratory.

Have any significant investments been made recently? Are you planning any investments in the nearest future? How the new investments can change your company’s growth trajectory?

Only in two-year period 2019-2020, we have planned and implemented investments for about 17 millions of euro. As already mentioned before, we are a company that invests a lot and tries to seize upon the opportunities offered by the market: this could mean keeping on investing in machineries to grow up internally, but also looking at possible takeovers of other interesting companies for us.

Are you planning to launch any new products in the nearest future?

Our range of products is in constant growing. Throughout 2021, we will launch on the market a very high performances new spiral hose, a new range of “push lock” fittings and many other innovations that we will gradually reveal.

Vitillo’s products are supplied in four continents and in more than 50 countries in the world, both directly through your logistic and distribution centres and through your business partners. Thanks to your direct presence in the most important strategic areas you can guarantee the best market coverage and manage peaks demand all over the world. Where are your main markets?

Mainly Europe, but we are also looking with great interest to US, North African and Asian markets too.

Who are your most important customers right now?

Some of the leading manufacturers of agricultural machineries, industrial compressors, and lifting platforms use Vitillo’s products. Just to name a few: ATLAS COPCO, Palfinger, Manitowoc, Manitou, Dalby, and ALO.

What are your plans for gaining new foreign markets?

Currently Vitillo brand is well renowned and appreciated in Europe, less known in emerging markets, which for us are interesting. In the nearest future, we will focus our efforts on making our brand and our quality known in these markets (South America, South-East Asia, and Australia). We will do this as always by letting our products speak for us, aiming on quality, trying to detect the specific needs of each target market.

World currently struggling with the consequences of a pandemic coronavirus. How do you evaluate the future of the industry in which the company operates, what are the company’s plans in connection with this?

Covid was an impossible-to-foresee tsunami. Luckily the company is well-structured and had its shoulders large enough to endure lockdown period, but the fact remains that there have been and there are still difficulties. Not only in terms of drop of turnover , that thankfully was limited , but above all due to the unavoidable slowdown that many of the projects we are carrying out have undergone. However, we trust that world can overcome in short time this phase and keep on running as usual. From our standpoint, Covid has made nothing but confirming the goodness of our growing strategy that aims to enlarge our horizons, in terms of market and of production. This strategy allows more flexibility and greater diversification of risk and, for us, it’s the winning path.