Symaga, an international and widely recognized company producing silos, is a perfect example of successful and sustainable business. Its well-balanced approach to investments in new technologies goes hand in hand with its help for local communities and numerous NGO’s worldwide.

More than thirty years after its beginnings in Villarta de San Juan, the company still supports the development of the region and sponsors a variety of local initiatives.

A great evolution

The history of Symaga dates back to 1985, when Alfonso Garrido founded a firm producing silos and livestock equipment in an agricultural village called Villarta de San Juan. The activity of the company had a very positive impact, helping to diversify its economy, and up to today Symaga remains an important motor of economic growth of the region. We could quote a lot data illustrating the immense development of the company, including the process of its modernization and the implementation of the newest technologies on European level, but let’s start with a simple, yet meaningful, comparison. At the beginning, the production of silos in Symaga was manual and it required four people and 38 hours to make a silo, while nowadays the company produces 100 silos a day and there are only 2 people required for this task. Ever since its beginning, Symaga has not ceased its development, both in the field of modernization of the plants and in the field of human capital and neither has it stopped increasing the number of national and international sales. Among the crucial moments in the company’s history we can mention its opening for new national markets and the beginning of its presence on international market in the 80’s. The development brings also new challenges: a standardisation of product and shorter delivery time is required. In order to meet these requirements, Symaga invests in mechanisation and increases the number of employees to 20. In the 90’s the internationalisation of the company continues, as the collaboration with foreign companies and exportation of products to European and South African countries increment. Nowadays, Symaga possesses facilities in more than 140 countries.

Beating new records

In 2017 the company beats its own record in production, reaching the number of 37 million tons and exceeding by 10% the results from 2016 and 2015, which up to this point have been considered the most successful years. The growth of production is related with a growth of employment – the number of employees of Symaga in 2017 reaches a top number as well: 250 workers. Moreover, the company received many prestigious titles and prizes, such as the Escolástico Zaldívar award in 2015, the PYME Innovadora seal in 2016, or the Award of Business Merit in the category of Export Companies in 2017.

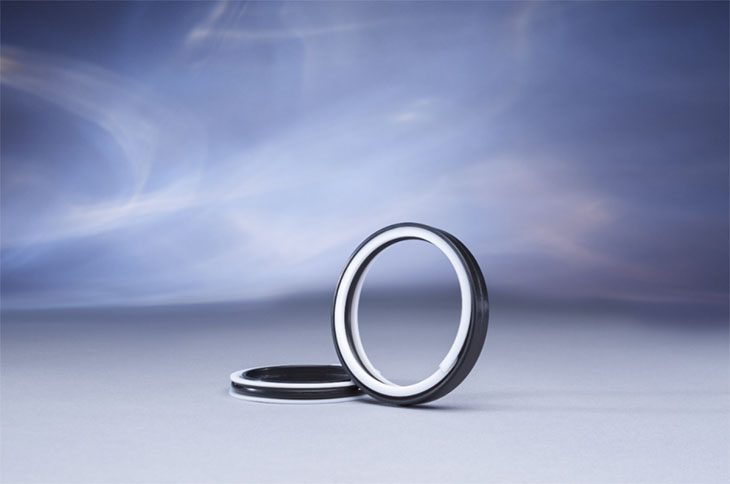

Products

Symaga offers a variety of industrial silos and accessories, which are used in breweries, feed mills, port terminals, grain mills, bioethanol plants and in many other places. The maximum capacity of a silo with a base made of concrete is 25 000 m³, while a hopper silo (with a diameter of 12 m and a hopper of45°, 60° or 66°) can have up to 2,643 m³ of capacity. The silos produced by this company are known for their durability and they are said to be easy to put up. The covering Z600 guarantees that the lifespan of the silos produced by Symaga exceeds the standard lifespan offered by other manufacturers.

Professionalism and openness

Currently Symaga employs 250 workers and it has created a special entity called Project Department, which is formed by Project Managers. This department is dedicated to the coordination of installations of Great Capacity, which required a perfect planning and organisation of technical, commercial and logistic teams, from the project and up to the delivery and installation. Despite that the company can rely on a team of experts, it still remains open for new talents and ideas. Symaga gives students an opportunity to undertake an internship in the company and enables young people without experience to start their professional career. Thanks to collaboration with Technical University of Madrid, Bipree Research Group and Metal Technological Center of Castilla - La Mancha (Itecam), the company supports and inspires new technological projects.

The key to success

The great evolution and success of this company certainly would not have been possible without high standards of production and a great contact with the clients. Symaga implements the newest technologies (for example, robots for folding and welding, or lasers for precise fabrication of steel elements) in order to guarantee the highest quality and precision at every part of the process, from production to distribution. It collaborates only with carefully selected suppliers which are considered the best steel mills in the world. It is also worth noting that the company possesses a totally automatized plant - the first one in the sector which obtained the CEmarking. Among the most important strategies in the present times, Symaga indicates investments in I+D+i (Investigation, Development and Innovation) and the policy of profit reinvestment. Both strategies aim at expansion, both on national and international level, thanks to investments in the newest technologies, as well as in human capital. When it comes to the relations with the clients, Symaga manifests a personalized approach,trying to meet the real needs of the buyers. The Export Area Managers are of various nationalities and origins, thanks to which an objective knowledge of a particular market and a multilinguistic approach is guaranteed. Moreover, the team visits over 100 countries a year, taking part in local festivities and industrial missions.

What really matters

It seems clear that for Symaga it is the values, and not only the economic success, that determine the way. According to its Corporative Social Responsibility Plan, the everyday activity should be developed in an ethical framework, respecting the environment, as well as a personal and corporative development. On the one hand,the company collaborates with numerous foundations and NGOs, such as AFIM, Red Cross, Manos Unidas, Coraje, AECC, Afanion, Supernenas, AELIP and NIPACE, and each year it makes a special donation to an association or collective. In 2017, for example, it supported NIPACE, a foundation which helps children with cerebral palsy.That year, Symaga helped also AELIP (International Association for Families and People Affected by Lipodystrophies) and Supernenas (a group of women affected by cancer who organised a self-help group. On the other hand, Symaga keeps on supporting diverse activities in its region, such as sponsoring a local football team, supporting the organisation of tournaments and races, or helping an athletic club in Villarta de San Juan and football camps in neighbouring villages, for example in Herencia. Apart from its support for sport initiatives, the company contributes to the renovation of buildings, such aschurches.

A glance into the future

During the next year Symaga is planning to continue investing in the newest technologies, in order to guarantee that the silos have a total traceability. The investments are centred on the lines of profiling and punching, in laser and in the automation of welding. The company has already purchased new drills, a new profiler for the accessories and numerous robots, among which we can highlight a new automatized welding cell of the newest generation. Having in mind all the previous Symaga’s achievements, the future seems really bright.