SCM Fonderie is part of SCM Group, a technological world leader in processing a wide variety of materials: wood, plastic, glass, stone, metal and composites. SCM Fonderie specialises in the production of castings in grey iron and ductile iron from 100 to 5000 kg, starting with the single piece right up to the small, medium series. Castings are produced for a vast range of applications, in the following industrial sector at the plant at Villa Verucchio, in the province of Rimini: gear motors, plants and machinery, centrifugal pumps, compressors, earth movement and agriculture, engines, railways and the nautical industry. The company pays special attention to the quality control of its products and environmental protection. The SCM Foundry has over 70 years of experience and the production capacity which can reach 12,000 tons per year. The company constantly invests in research and development and the ability to cooperate with the client from the stage of product concept, through design, prototyping, to production.

Milestones in the company’s development history

SCM Fonderie has a success story that began over 70 years ago. The origins of the SCM Foundry date back to 1937, with the launch of a collaboration between the Lanfranco Aureli foundry and that of Nicola Gemmani and partners. Initially, the foundry specialized in castings of iron and other metals and was mainly targeted at the agricultural machinery sector. Over time its work turned increasingly towards the area of cast iron casting while those of other metals declined. In 1960, shareholders decided to establish a new company under the name SCM Fonderie. The company specializes exclusively in gray cast iron, spheroidal cast iron and compacted graphite cast iron (CGI) castings for the production of woodworking machines. This is a sector of competence of SCM, the other division developed by the two partners which resulted in the current leading Group in the machinery and components sector. With the evolution of the machine tool sector, where structures are increasingly made of steel and less cast iron, SCM Fonderie is definitely targeting the external market, specializing in the sectors of motion transmission, industrial machinery, agricultural and earthmoving vehicles, engines, as well as pumps, compressors and railway sector.

Reason to be proud

In its decades-long history, SCM Fonderie has also based its development and strength on the advantage of belonging to a leading group, in terms of know-how and technological innovation, such as SCM Group. The strong specialization in its own sector of expertise still blends today with the values of solidity, internationality and sustainable innovation that are typical of the Group, world leader in technologies for processing a wide range of materials and industrial components.

Key success factors

The main reasons for the success of SCM Fonderie, in an after all mature sector, lie in the strong orientation, not so much to the pure and simple melting process, as to additional services capable of attracting a selected and diversified clientele, such as:

- Codesign - product development together with the customer.

- Process and product quality integrated with environmental management.

- Continuous improvement of the product and manufacturing processes.

- Time to market adapted to the needs of the market.

- Complete supply with the possibility of processing finished components, surface treated, assembled and fully tested with consequent full control over quality aspects.

In addition to this. In the extremely competitive context of the foundry sector, SCM Fonderie has chosen to specialize in the production of complex and large-sized castings, with small quantities and even unitary lots.

Company production capacity

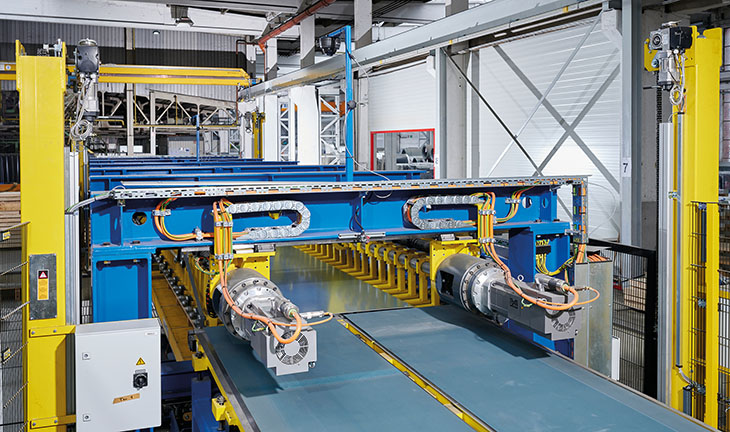

SCM Fonderie uses 80% of the current production capacity, which is 7,000 tons per year and employs 74 people. The company has been ISO 9001 certified since 2003 and ISO 14001 since 2007, and has also been EMAS registered since 2014. The environmental and quality management system has been integrated and managed by a team of both quality and environment specialists. SCM Fonderie is a foundry characterized by productions with a large number of cores and very complex assemblies, and the plants allow great flexibility, which allows the company to meet even the most demanding requirements in terms of reactivity and speed of delivery. With a view to digitizing processes in production departments, an IT system has been introduced containing all production information for each code, in particular each cast and each support containing the cast is identified by a tag with the appropriate barcode, which can be used to retrieve all production information. The main process improvements relate to aspects related to the mechanization of foundry operations such as casting and mold transport, while for products was developed the use of low-cost low-series casting models with unique batches.

Sales markets

After years in which the main clientele was exclusively Italian companies, recently SCM Fonderie won important orders from international clients, mainly located in Northern Europe. The type of delivery has also evolved accordingly, giving more and more space for the delivery of components including machining, assembled and tested, ready for use by end customers. The main customers are leading industrial groups in the sectors of gearboxes, earth-moving and agricultural machinery, industrial machinery, fluid mechanics, railways and, more recently, boats. The company believes that these customers chose SCM Fonderie because of its technical expertise in the development and industrialization of highly complex products and the exceptional flexibility of the manufacturing process. Quality and environment as well as safety are core values that allow the company to face the current and future market in a competitive manner. SCM Fonderie shares these values with its suppliers. The most important partners are companies that have both quality and environmental management systems.

Development strategy and plans for the future

SCM Fonderie continues its path in the search for highly specialized markets, where the focus is not so much on high volumes, but on the size and complexity of castings, which poses a serious barrier to the entry of many competitors and guarantees adequate added value. With this in mind, the investments are aimed at increasing the maximum weights and dimensions that can be achieved through the progressive mechanization of certain stages of the process (please note that this is a manual foundry), which, among other things, guarantees greater operator safety. One of the most important points for SCM Fonderie is the safety of its employees, in this sense the company has invested a lot and in the last year the number of accidents has been reduced to a very low level. Given the results in the coming years, SCM Fonderie will dedicate a large proportion of its investments to improving the working conditions of its employees. SCM Fonderie’s main goals for the next three years are growth and sustainable development. These two closely related aspects, in terms of the growth and diversification of customers and target sectors, should guarantee the company a certain amount of consistency in revenues over time and limit the peaks and valleys that have often characterized current production. What is a priority for the company’s management, this development must take place in an absolutely sustainable way for the environment, the territory, and all the subjects who interact with SCM Fonderie.