Outotec has agreed with OJSC Svyatogor, a subsidiary of Ural Mining and Metallurgical Company, to provide Outotec® Ausmelt technology to the Svyatogor smelter modernization in the Ural region, Russia. The contract value is approximately EUR 10 million which has been booked in Outotec's fourth quarter 2014 order intake.

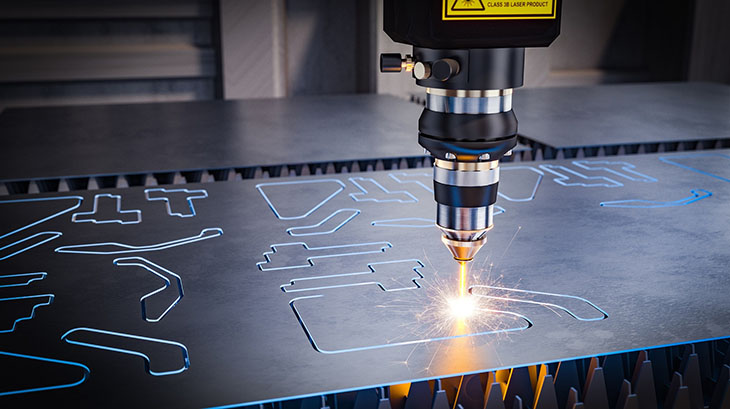

Ural Mining and Metallurgical Company is the second largest copper producer in Russia. The Svyatogor primary copper smelter is currently roasting concentrate in multi-hearth furnaces and smelting it in reverberatory furnaces. Adopting Outotec® Ausmelt technology to replace the current roasting and smelting phases will improve efficiency and environmental performance of the Svyatogor operations as well as reduce production costs.

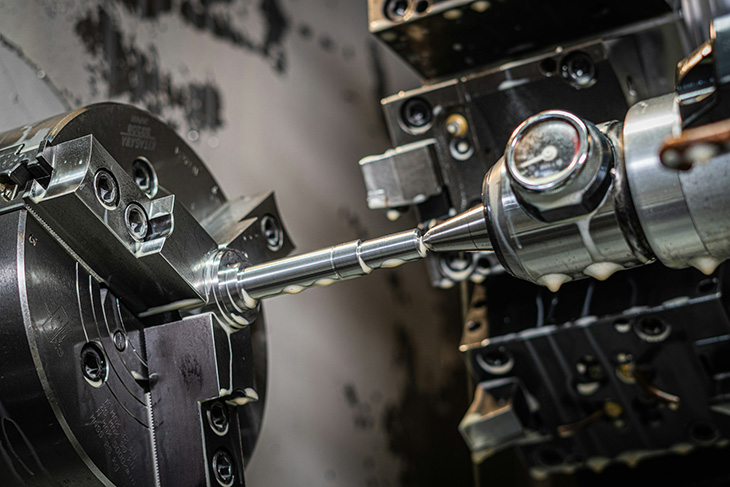

Outotec will provide detail engineering, proprietary equipment and advisory services for a new copper smelting furnace capable of processing more than 500,000 tonnes of copper concentrates per annum. In 2013, Outotec provided a technology license and basic engineering for the same project. The smelter is expected to be operational in 2018.

"We are very pleased that OJSC Svyatogor has chosen Outotec's sustainable smelting technology for its modernization project. It demonstrates their commitment to operating environmentally sustainable metals business", says Robin Lindahl, head of Outotec's Metals, Energy & Water business area.

Outotec acquired the Ausmelt technology in 2010 to complement its technology portfolio in environmentally sound smelting technologies for copper and nickel smelters as well as solutions for ferrous metals, zinc, lead and tin concentrates, zinc bearing residues, recycling and various secondary and waste materials.