Nordkalk operates in 30 locations in 8 countries. The headquarters of the corporation is in Finland. In Poland, Nordkalk began operating in 1997, the head office of Nordkalk Sp. z o.o. is located in Krakow. Currently, production takes place in 4 plants: Miedzianka, Wolica, Sławno, Szczecin.

Mr. Piotr Maciak, Chairman of Nordkalk sp.z o.o. / Sales Director Central Europe gave an exclusive interview especially for Manufacturing Journal magazine.

What were the origins of Nordkalk and what were the most important moments in its development history? What achievements are you most proud of?

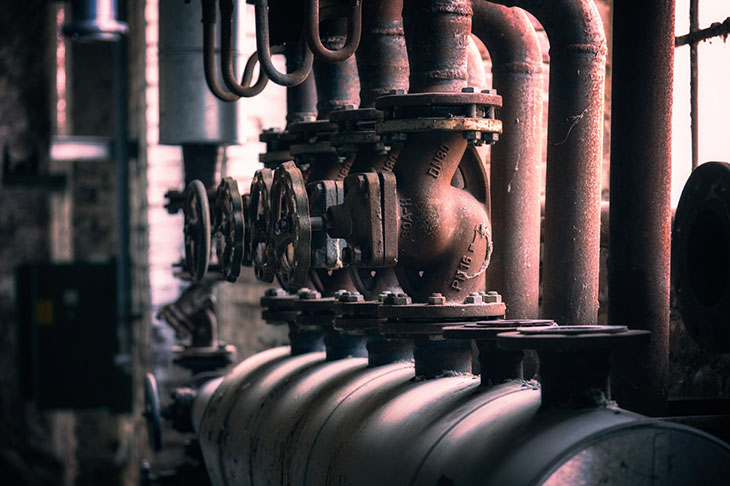

The surge in demand for limestone, which is one of the key raw materials used in industry, is of course related to the industrial revolution that began at the beginning of the 19th century. With the development of railways, factories, steel mills, and the glass industry, it turned out that the demand for limestone was growing. For the burning of limestone, special furnaces, the so-called limestones, some of them were used until the second half of the 20th century. That is why the history of Nordkalk begins at the end of the 19th century in the city of Pargas in the south of Finland. A turning point in the company’s history was the first meeting of the Pargas Kalk Aktiebolag Board of Directors on November 26, 1898, at which local farmer Otto Moberg was appointed managing director of the recently operating quarry. Moberg was a man with a vision who understood the need to increase the existing extraction and processing of limestone in Pargas, as well as to hire specialists and engineers responsible for the production process. The limestone mined in Pargas was processed and sold to paper mills, steel mills and pulp mills, and began to be used for the production of cement. In turn, crushed limestone was used primarily in agriculture. With the dynamic development of the company in the 20th century (operating under the name Partek) and the modernization of production lines in the early 1990s, the company adopted the name “Nordkalk”. The activity was extended to neighbouring countries - Estonia and Sweden, and in 1997 the first Polish Nordkalk office (initially as Partek Nordkalk) opened in Gdańsk. In 1999, a limestone plant and deposit were purchased in Sławno, and a year later a new grinding plant was launched in Szczecin, serving not only Polish but also other Nordkalk plants. The turning point in the company’s history in Poland was the acquisition of shares in Kielce Zakłady Przemysłu Wapienniczego in Miedzianka. In this way, he became the owner of one of the largest limestone deposits in Poland. In 2001, Nordkalk received a mining permit from the deposit in neighbouring Wolica, where a new mill was also built. We are proud that Nordkalk Polska is an essential part of the entire Group. From the beginning, we have invested over PLN 150 million in the country in modernizing our plants, building new production lines and crushing limestone, developing new technologies for obtaining the product, but also reducing the impact of our activities on the environment, and above all on the inhabitants of nearby towns.

Nordkalk is a leading Northern European supplier of limestone products and solutions. Can you tell us in more detail about the products offered, mining technologies and the company’s production facilities?

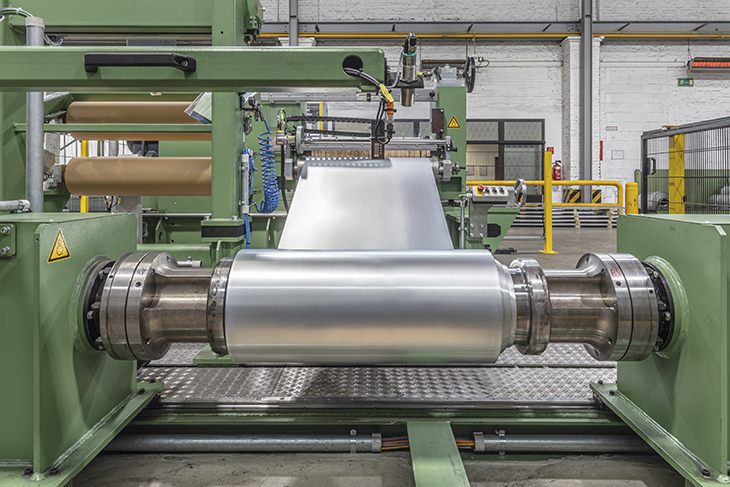

Nordkalk Polska produces limestone mainly for the domestic market - for companies operating in Poland. The aggregates market is quite scattered, with many smaller plants. Nevertheless, as Nordkalk, we are one of the largest producers with access to resources - our mines currently supply around 12% of the supply to the market. The mining technology is based on the performance of blasting works that result in the limestone rock mass breaking off. In this way, terraces characteristic for the exploited deposits are created, on which the output is transported to the plant. The processing works take place in the plant itself - crushing, grinding, division into fractions, then loading and transport to the customer. Limestone is used in many industries important for the Polish economy - from construction, through industry, to agriculture and energy. A large recipient of limestone-based products - aggregate, limestone and dolomite flour - is the construction and infrastructure industry. Nordkalk aggregates are the environmentally friendly and cost-effective choice of a road construction solution. We offer a wide range of different aggregate fractions for many applications, including the production of high-quality concrete, concrete products, prefabricates and paving stones. For buyers of this product, its homogeneous chemical composition is of key importance, which allows creating an additional bond between the cement slurry and the aggregate. The product improves the strength parameters of concrete and contributes to increasing the cost-effectiveness of cement. All aggregates meet the highest requirements of European standards. A separate plot is also for liming products used in agriculture. Liming soil effectively improves retention and protects groundwater and prevents contamination of surface waters.

Products based on limestone are used in road engineering, construction, metallurgy, sugar, glass, as well as agriculture and the energy industry. Who do you specifically address your offer to and what distinguishes it from the competition?

Due to the very high quality of limestone obtained in the White Basin of Poland, i.e. the Świętokrzyskie Voivodeship, we are strongly present in the metallurgical industry and energy production - our products are used in flue gas desulphurization installations in power plants and as a flux in steel production. In the last quarter of a century, a significant number of flue gas desulphurization (FGD) installations were built in the Polish power industry, which allowed the total SO2 emission to be reduced four times to 0.4 million Mg in 2013, and the share of SO2 retained in these installations increased to over 80% in 2013. Therefore, the domestic demand for lime sorbents increased from practically zero in 1990 to about 2.5 million Mg annually in 2016, and the energy sector became one of the most important recipients of the Polish lime industry. High-quality limestone is also used as a flux in the steelmaking process. To produce a tonne of steel requires over 50 kg of quicklime! Additionally, the steel industry uses calcium products to purify water in the same way as the mining and metallurgical industries.

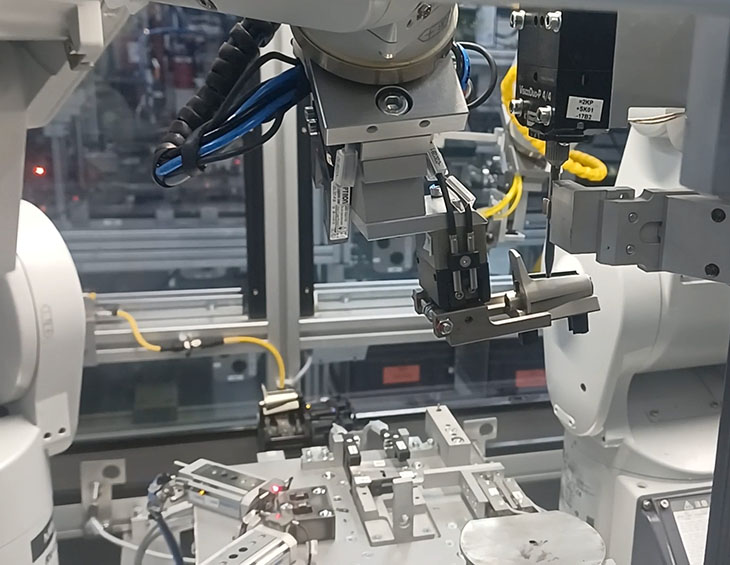

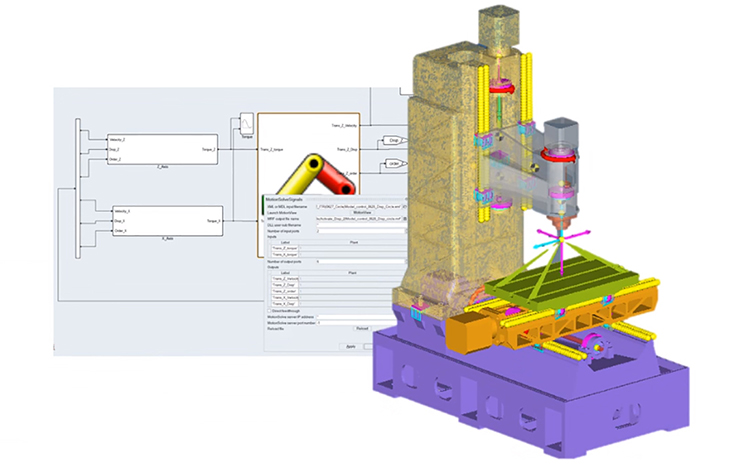

The industry is bolder and bolder in focusing on research and development and the development of new technologies. Is Nordkalk also in line with the Industry 4.0 trend and investing in the latest technologies and solutions?

From the beginning of our operation in Poland, we have been constantly implementing plant modernization programs. The conducted modernizations were aimed at optimizing production, reducing waste according to the “zero waste” principle, introducing new product categories, improving employee safety, as well as reducing emissions and the impact of activities on the environment and residents. As an example, we can give a new production line launched in Wolica in 2017. We have invested in a modern semi-mobile crushing and sorting set, which includes: a crushing station, a screening station, a charging hopper and belt conveyors. The semi-mobility of the set means that it can be moved to different levels of the mine, depending on the availability of the raw material, which allows you to significantly optimize production processes. In total, as I said, Nordkalk in Poland has invested 150 million in the development of its plants.

Please tell me what is the most important in your business? What is the strategic potential of your company and the key to its success?

The company is primarily people, product and the values it represents. We are lucky to be a supplier of a product that is indispensable for industry, energy and infrastructure construction, which makes it crucial for the national economy, and at the same time is natural and ecological. Thanks to limestone, agriculture gains ecological fertilizer, and the soil has a proper pH. As a completely natural product, limestone also helps to protect the environment through water retention and purification. Our values - openness, honesty, modesty, trust and respect - guide us in our daily work.

Achieving success in business is impossible without qualified staff. Can you tell about Nordkalk’s team of specialists?

In the Świętokrzyskie Voivodeship, where the unemployment rate is one of the highest in Poland, we, in turn, are one of the largest employers in the White Basin. We have experienced professionals, engineers and production workers on board. At Nordkalk you can meet employees who have been with us for 20 years! It would not be possible without investments in development, training and mentoring programs, investments in safety and improvement of working conditions.

The quality of the products and services offered is your priority, which is why you cooperate only with proven partners. Would you like to highlight any companies - your most important suppliers, subcontractors or other partners?

We have many subcontractors for whom we are a reliable business partner, at the same time expecting their commitment, the highest quality services and maintaining the highest safety standards. We try to cooperate with local companies, thus stimulating the development of the region. One of such companies is the company Budpol Sp. z o.o. We have been cooperating with for over a decade in the field of high-performance raw material haulage and auxiliary services at the Miedzianka plant. Transporting the right amount of raw material from the mine to the processing plants is undoubtedly a special and sensitive element of ensuring the production process, which directly affects the achieved efficiency parameters. Budpol was one of the first companies in Poland to implement a raw material haulage based on four-axle trucks adapted to work with a mining plant, and the applied solution works and allows to achieve high efficiency and operational availability with low diesel consumption at the same time.

What are the most important investments related to the company’s development over the past few years? Are you planning new investments?

All Nordkalk plants in Poland, starting from Szczecin, through Sławno, Wolica and Miedzianka, have undergone a thorough modernization process. Within ten years of opening the first office in Poland in Wolica, the company launched a mill and started the production of limestone flour. In turn, in Miedzianka, a crushing installation was built and modernized, and then a new limestone crushing line and an extended railway siding were installed. In 2016, a new line for the production of lime granulate was officially opened at the Nordkalk Plant in Sławno commune. It is impossible to really list all the investments we have made to make the company such a modern and safe facility. Our investments will also be related to the sustainable development strategy and ambitious goals that we want to achieve by 2045. We strive for 100% material efficiency and a circular economy. We continue to work systematically to increase material efficiency and utilize all extracted material, as well as increase efforts in circular solutions. For example, the plant in Miedzianka currently has an efficiency of 98%, which is a very good result. In production plants, we launch programs based on the principles of lean management, which are supposed to optimize the entire production process. At the Nordkalk plant in Gotland, where such a program was implemented, the total savings exceeded EUR 1.5 million. A circular economy strives for total material efficiency and maximum use of its own production streams. Our goal is to find new, high-performance solutions produced in a closed-loop process, in which waste from one process is used as raw materials for others, which minimizes the amount of production waste. Nordkalk’s sustainable development strategy places emphasis on reducing emissions and the climate impact of our operations. We have now set long-term goals for climate change mitigation efforts and have started work on a roadmap to fossil fuel-free operations. Our goal is carbon neutrality by 2045. For limestone and inland shipping, the target implementation period is 2035. One of the important elements of our activity is monitoring local environmental impacts, such as dust, noise and vibration, as well as taking care of the development of dialogue with local communities.

Apart from business activity, pro-social activity is equally important. Are you locally involved in non-sectoral activities?

We are strongly involved in activities for the benefit of local communities. We have launched the project of the Social Dialogue Council, i.e. meetings of representatives of local communities with Nordkalk, the purpose of which is to learn about the needs of these communities and jointly implement selected projects. The submitted projects must meet certain requirements in order to be implemented: they are relevant to the community; are long-term; they are not profit-oriented, they relate to at least one of the areas of the company’s activity in the area of social involvement. In 2020 alone, 11 projects were submitted. A two-way dialogue has been established, respecting the points of view of both the residents and Nordkalk. Some of the projects concern infrastructure - repair or construction of a pavement, well, gazebo for meetings, repair of the road surface, co-financing of the construction of a playground or assistance in the renovation of monuments. We are still developing this initiative. At the same time, we provide other forms of support, such as organizing trips or summer camps for children of the inhabitants of nearby towns, financing local sports teams, and planting trees. In 2021, together with the Phacops Society of Earth Sciences Friends and the Polish Academy of Sciences, we are starting a series of lectures on palaeontology for children and youth from the Piekoszów commune, where the Miedzianka Institute is located.

The received certificates and distinctions are the confirmation of the high-quality functioning of the company and the offered products. What are the most important certificates, awards and titles you can be proud of?

These are global certificates confirming the implementation of quality management systems, regional awards such as Business Cheetahs, of which we are laureates, and numerous competitions in which our products win statuettes. An example is the emblem of “Good Brand - Quality, Trust, Reputation 2019” or “Brand of the Decade” awarded to Nordkalk AtriGran lime in 2019. However, we are not resting on our laurels! We want to continue to invest in the development and quality of our products and support regional development and the Polish economy.