Pharmstandard is one of the leaders in the pharmaceutical industry in Russia. The Group is developing and producing modern, high-quality and affordable medical products.

Today, the most well-known medicines manufactured by Pharmstandard Group are Arbidol®, Complivit®, Pentalgin®, Flucostat®, Phosphogliv®, Amiksin®, Afobazol®, Kombilipen®, Octolipen®. In total, Pharmstandard Group produces more than 300 types of medicines, including products for the treatment of cardiovascular diseases, diabetes, growth hormone deficiency, gastroenterological, neurological, infectious diseases, metabolic disorders, cancer and other diseases. Collective production facilities of the Pharmstandard Group allow to produce more than 1 billion packages per year. Production facilities are provided by modern plants that meet all the requirements of Russian standards: Pharmstandard-Leksredstva, Pharmstandard-UfaVITA, Pharmstandard-Tomskkhimpharm, “Biomed” I.I. Mechnikova, “Lekko” and “TZMOI” Medical Equipment Factory. According to the results of 2017, the Group produced 0.625 billion packages of medicines and 832 units of medical equipment. Pharmstandard’s consolidated revenue for 2017 amounted to 70 billion rubles. EBITDA amounted to 15.3 billion rubles in 2017. Net profit amounted to 11.3 billion rubles. The total number of employees is more than 6.5 thousand.

Pharmstandard-UfaVITA (Ufa)

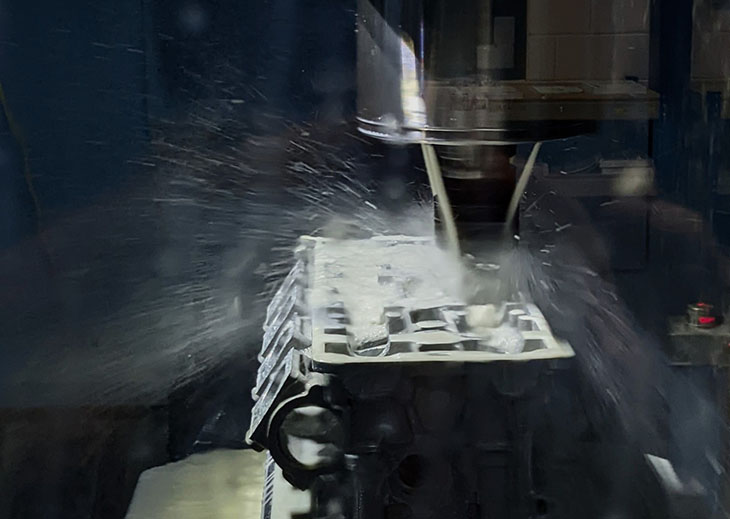

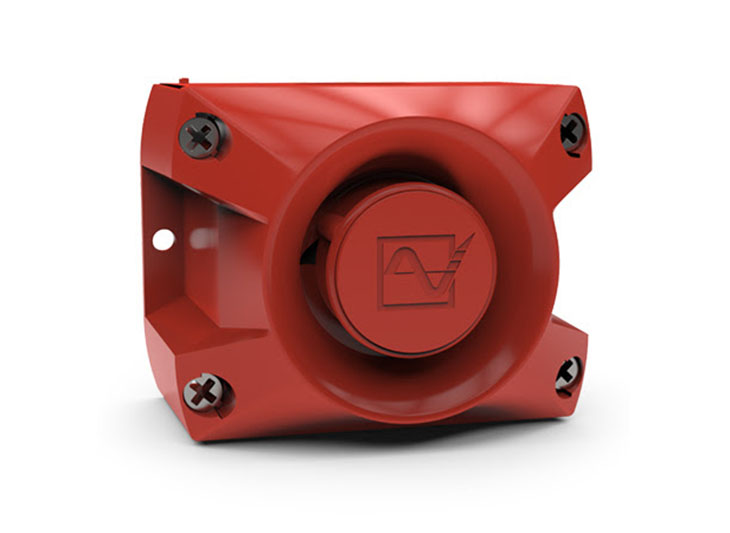

Pharmstandard-UfaVITA accounts for almost 15% of the total production of the Group (or over 90 million packages of medical products). This company employs more than 1,700 people and produces more than 100 different products. The company has 19 production lines, the total production capacity of which exceeds 170 million packages per year. Pharmstandard-UfaVITA has all the capacity necessary to ensure production: operating production workshops, storage facilities necessary for storing raw materials, materials and finished products, laboratories of the quality control department performing quality control of raw materials, packaging materials, intermediate products purchased and finished products. To provide energy resources, the company is equipped with: a gasified boiler house, two independent power inputs, oxygen and nitrogen generators, and a compressor room for producing compressed air. Production sites are equipped with systems for obtaining purified water and water for injection.

The company organized the following production: solid non-sterile dosage forms: tablets and coated tablets (including film-coated), pills, capsules; liquid and lyophilized sterile dosage forms: injection preparations in ampoules, vials, cartridges, prefilled syringes. All production lines of capsules, tablets, injectables are created in accordance with the requirements of GMP and are full cycle production, which includes all stages, ranging from the preparation of raw materials to the storage of products.

Pharmstandard-UfaVITA is one of the largest Russian pharmaceutical manufacturers. The company is a leader in the production of mono- and multivitamin preparations; also, the plant produces antiallergic, cough and cold, anti-inflammatory, antiviral (HIV), antituberculosis, antitumor, hepaprotective, immunomodulatory, immunosuppressive, nootropic, metabolic, analeptic, hypoglycemic and other products. The plant joined the Pharmstandard Group of companies in 2003. Over the past 12 years, there has been a continuous process of modernizing the plant and launching new lines. More than 15 projects for the reconstruction of existing industries were implemented, 12 new modern sites were put into operation that fully comply with the EU and Russian GMP requirements:

- Workshop No.4 for injectables — manufacturing of injactables in ampoules with terminal sterilisation;

- Workshop No.4 for insulin products – aseptic manufacturing of products in vials and cartridges;

- Workshop No.1 for multivitamins — manufacturing of film-coated tablets;

- Workshop No.4 for lyophilized products — manufacturing of lyophilisates for injection solutions;

- Workshop No.5 for injectables — expanded manufacturing area for injectables in ampoules.

- Put in commission liquid dosage form packaging area (Workshop No.5).

Launched contract manufacturing of F.Hoffman—La Roche cold-chain products. In 2017, the construction of a new building for the production of FPP with a total area of 10,030.9 m2 (6 floors) for the location of production and laboratories was completed. Pharmstandard-UfaVITA complies with GMP requirements on all production lines of the enterprise. The quality management system is certified for compliance with the requirements of GOST R ISO 9001-2015, and this compliance is annually confirmed.

For nearly 20 years, the company has been headed by Vladimir AdolfovichKreiman. He graduated from the Novosibirsk Electrotechnical Institute and obtained the qualification “Mechanical Engineer”. Vladimir Adolfovich went through a significant professional career from a junior researcher at the Institute of Mining, Siberian Branch of the USSR Academy of Sciences to the head of one of the country’s largest pharmaceutical plants. He has 11 copyright certificates and patents.

Further stages of development

Pharmstandard-UfaVITA develops in accordance with the approved strategic development plan, according to which new capacities are introduced to expand the company’s range of products. Modernization and optimization of existing capacities is carried out, which will improve the quality of products, introduce modern automation systems to increase the efficiency of the production process.

In 2018, it is planned to expand the range of the manufactured products:

- to develop 5 original formulations;

- to localize (technology transfer) 38 items, including: full cycle — 33 items; secondary packaging — 5 items;

- to reformulate, repackage — 22 items;

- to commission stage by stage the manufacturing facilities and laboratories in the new building (during 2018-2022);

- to build the treatment facilities (to be commissioned in the 3rd quarter of 2020).

Until 2021, the phased launching of production and laboratories in the new building is planned: Stage 1 - domestic premises and the Central Factory Laboratory (implemented in Q2, 2018), 2nd stage - organization of the production of solid dosage forms, including those coated with various types of shells. 3rd stage - the production of liquid dosage forms. As a result of the work done, the production capacity of the plant for the production of tablets will increase by at least 30%, and the level of manufacturability of the enterprise will be even higher.

Development strategy

In 2014, the Government of Russia announced its intention to restructure the country’s economic development model and switch to import substitution of technologies in strategically important sectors, including the pharmaceutical industry. Following this policy, since 2014, Pharmstandard-UfaVITA has localized the production of 60 products (technology transfer), while the depth of localization of production has increased annually. So, if until 2014, not a single medicine was produced for the full cycle, by 2018 almost half of the localized medicines are the products of the full cycle. The share of domestic medicines in the production structure is also growing and is already at least 37%. Company expects that the import substitution policy will continue to have a positive effect on the industry as a whole in the medium term. In the short term, there is still an incentive to localize production by foreign companies. In 2017, the main increase in revenues of its own high-margin medical products in the pharmaceutical portfolio of the Pharmstandard Group was provided by medicines produced at Pharmstandard-UfaVITA: Combilipen and Phosphogliv. The share of these products increased from 24% to 29% of the revenues of all products of the Group. Pharmstandard’s development strategy is aimed to have greater revenues primarily due to increased production of medicines with a high rate of return, affiliate programs, which means production of medicines from outside organizations, increased participation in government programs, production of new medicines, expansion of the range of dosage forms and dosages. This strategy should be implemented in terms of optimization and expansion of production capacity of Pharmstandard-UfaVITA.

Partners of Pharmstandard-UfaVITA

Pharmstandard-UfaVITA cooperates with many of the world’s leading manufacturers, such as AbbVie, Celgene, Sanofi, GEHelthCare, Johnson & Johnson, Eisai, Ferring, Merck, Novartis, Roсhe, Amgen, trying to localize medicines which are needed for treatment in Russia, trying to make them more accessible for patients.