The quattroClean snow-jet technology has established itself as an economical and reliable process for the partial and full-surface cleaning of a wide range of parts. A newly developed two-component ring nozzle for a pulsating jet now enables further cost savings and technical advantages to be realized in CO2 cleaning operations.

In today’s quality-oriented production processes in all branches of industry, parts cleaning is an indispensable step. The cleanliness specifications to be fulfilled vary according to the product, the manufacturing phase, and the next process in the production chain, such as coating, joining, assembly or packaging. Whatever the case, the trend is increasingly towards dry cleaning processes, such as acp systems AG's quattroClean snow-jet technology. These ensure reliable cleaning results in line with requirements and are easy to integrate into production lines and connected manufacturing environments. The environmentally friendly alternative to wet chemical processes also offers advantages if only specific areas of a part require a defined level of particulate and/or filmic cleanliness, such as bonding, welding or sealing surfaces, or when it comes to cleaning ready-assembled components. Furthermore, the technology can be used to clean and deburr hard and brittle plastics like PEEK and PPS simultaneously.

Four effects for consistently clean surfaces

The cleaning medium used is liquid, non-corrosive carbon dioxide, which has an unlimited shelf life. A by-product of chemical manufacturing processes and biogas energy generation, this cleaning medium is environmentally neutral.

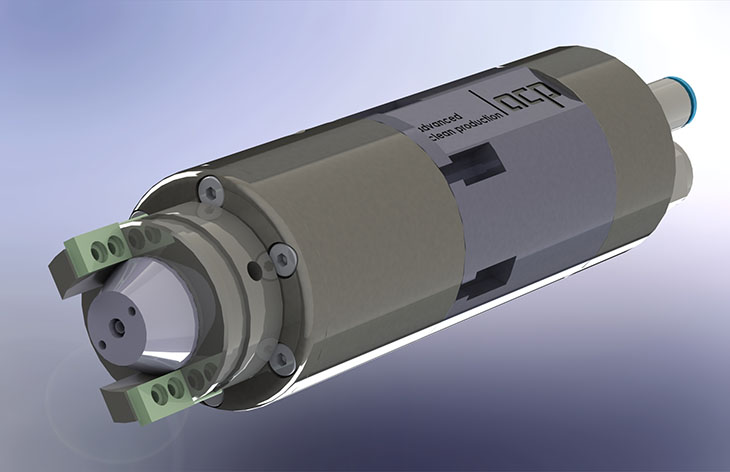

The core of the cleaning system is a wear-free, two-component ring nozzle through which the non-flammable and non-toxic carbon dioxide is fed. On exiting the nozzle, the carbon dioxide expands to form fine CO2 snow, which is then bundled by a separate jacketed jet of compressed air and accelerated to supersonic speed.

When the easily focused jet of snow and compressed air impacts on the surface to be cleaned, a combination of thermal, mechanical, sublimation and solvent effects occur. The interaction of these four mechanisms of action reliably removes particulate and filmic contamination. The aerodynamic force of the compressed air carries away the detached contamination, which is then removed by an integrated extraction system. Since CO2 sublimates instantly under atmospheric pressure, the parts are dry at the end of the cleaning step and immediately ready for further processing or packaging.

Higher cleaning efficiency thanks to new nozzle technology

With the aim of increasing cleaning efficiency even more and broadening the range of application, acp has further developed its nozzle technology. The result is a nozzle technology that generates a pulsating jet with a frequency of 25 to 30 Hertz. The pulsating jet of snow and compressed air has a higher kinetic energy than a continuous jet, hence the optimized cleaning effect. For one, the effect of the micro jets (mechanical method of action) is multiplied. This is due to the impulse transmitted when the fine snow crystals impact at high speed on the surface to be cleaned or deburred. Secondly, each time the pulsating jet strikes the material, an approximately 600-fold increase in volume takes place during the transition from the solid to the gaseous phase (sublimation effect). This causes repeated micro-explosions that enable contaminants to be removed more effectively.

Shorter processing times and lower costs

Thanks to the increased effectiveness of the jet, in many applications the already short cleaning times can be reduced even further. The enhanced impulse transmission also improves the efficiency of deburring tasks, so that processing cycles can be shortened here as well.

This opens up new perspectives, especially if the quattroClean system is integrated into automated production steps with very short cycle times. Corresponding trials are carried out by the company in its own technical center. The pulsating jet can also reduce the consumption of carbon dioxide and compressed air, thus cutting cleaning costs per part and contributing to higher economic efficiency. Furthermore, the snow-jet cleaning system with pulsating nozzle is both lightweight and compact.

Highly flexible systems tailored to requirements

The company develops customized system concepts based on standard modules that are adapted to the respective cleaning and cycle time requirements. The systems can be designed as stand-alone solutions or can be integrated into automated or connected manufacturing environments. The scalable quattroClean process can be adapted to different component geometries for partial or full-surface processing in an efficient and space- saving manner. Through tests in the technical center, all process parameters such as the volume flows for compressed air and carbon dioxide, as well as the duration and area of application of the jet, are precisely tailored to the case in question, taking the properties of materials and the contamination to be removed into account. These parameters can later be filed as part-specific cleaning programs in the system controls. Standardized interfaces allow easy integration into higher-level host computer systems for subsequent control. To ensure full documentation and traceability, all process parameters are automatically recorded and transferred to the host computer.

Contact:

acp systems AG, Karl-Heinz Menauer, 71254 Ditzingen, Germany, Phone +49 7156 480140, www.acp-systems.com