Most modern touchscreens are multi-touch. Using two fingers to zoom in or out on a smartphone or rotate an image on a tablet – these are gestures that are so normal that most people hardly notice performing them. Interfacing through multiple simultaneous points of input is just how people think and interact with technology.

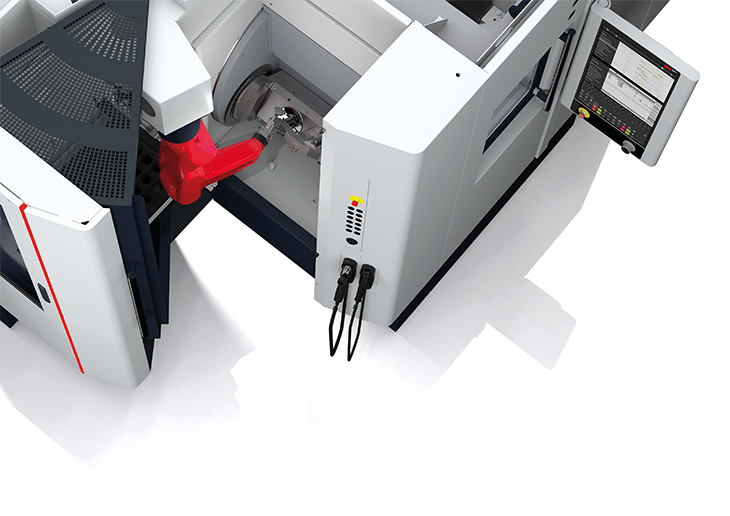

Schwäbische Werkzeugmaschinen GmbH (SW) is a leading machine, automation and system solutions supplier, known internationally for the usability of its sophisticated multi-spindle machines. The company has incorporated multi-touch capabilities into their recently released CNC HMI, the C|one Control Panel. Additional improvements include simplifying program management and troubleshooting to streamline the overall user-experience.

Modernized HMI

The main display of the C|one, in addition to its multi-touch capabilities, is 24-inches and features increased haptic feedback. This feedback imitates the feel of real hardware buttons to prevent incorrect operation, while also enabling blind operation of functions. An intelligent touch-sensor additionally prevents accidental input due to water and dirt. A multi-functional rotary dial will provide precise for feed and spindle override, which can also serve as a handwheel.

Simplified Troubleshooting

When a fuse blows (a problem with a simple enough solution) it can quickly be buried in a traditional NC by the subsequent alarms it triggers. Instead of spending a lot of time with the machine down digging for the root cause, the C|one makes the problem clear, ultimately cutting downtime. It will indicate initial alarms, even when they cause a domino effect.

Program Management

Among the tasks improved by the C|one is managing programs. Program history and the programs saved in the NC are viewable. The most recently selected programs are saved as history and up to five programs can be saved as favorites per table. Timestamps for file changes are tracked. Subprogram files and main program files are easily switched on the display as well as the workpiece folders depending on the needs of the operator. Table dependent programs can be selected and deselected and these actions are tracked for straightforward review.

Optional features

Secondary control panels will eventually be replaced with 10.1” screen tablets. They will feature the secure Windows 10 IoT Enterprise operating system, which is the same OS used by many point-of-sale devices and ATMs. The tablet will have a battery life of up to 8 hours. The secondary screen eliminates the need from running back and forth from the control panel every time a tool needs to be loaded or seeking help from another shop floor employee to assist.

Further innovations to come

Additional features are being explored for implementation in the C|one in the near future, for example, advanced tool management. Everything a user will need to know about their tools will be in one place on the C|one. Tool status will be indicated through straightforward icons. This type of monitoring, known as ‘condition monitoring,’ allows users to stay on top of what’s going on, so they know what to address before it has the chance to become a problem. Furthermore, users will have the ability to customize the tools visible at any given moment through a clean, modern tool management UI, which dynamically presents the relevant information such as hiding and unhiding the cutting edges of tools. Tools will be able to be edited, loaded, deleted and created and tool properties are grouped and can be dynamically hidden and unhidden. Import and export functionalities for tool data are currently being tested on the secondary tablet so that users can take that information with them from one machine to another. Modernization is the key to continuing success in manufacturing and the new C|one Control Panel has been designed to enable IoT and Industry 4.0 adaptation.