Göppingen/March 10, 2021 – Leading press and line manufacturer Schuler is accelerating the digitalization of its product portfolio as a customer productivity driver. With the “Digital Suite”, the Göppingen-based technology group presents the first virtual product platform that allows users to test, configure, and order the entire spectrum of existing and new digital Schuler solutions for forming technology.

Through the Digital Suite, existing and potential customers also have direct access to product experts from Schuler, who are the go-to contacts for discussing specific application cases and requesting additional detailed information. Rohitashwa Pant, Chief Digital Officer (CDO) at Schuler, explains: “Our goal is for each product in the Digital Suite to be able to help reduce unit costs and increase the efficiency of machines and systems at the customer end. The use of open interfaces and standard technology makes our products easy to integrate into customer IT networks. The fact that we’re now making our networked solutions available on a virtual platform in a bundled format shows that digitalization in forming technology is becoming increasingly important, and that Schuler is playing a leading role in this process.”

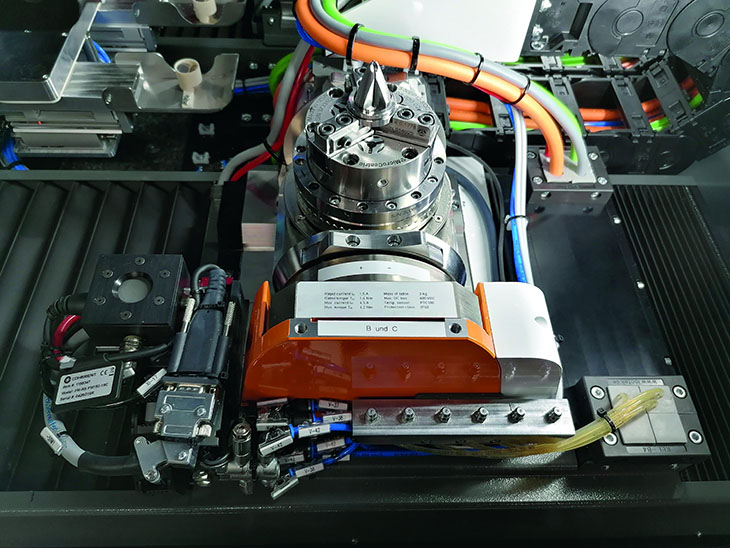

Products in the Digital Suite include Schuler Connect as a virtual service system for troubleshooting without on-site technicians, improved Track and Trace solutions for end-to-end performance monitoring of components in a press as well as Visual Die Protection, which uses artificial intelligence for the advance identification and elimination of imminent sources of damage where dies are used.