Turning is one of the oldest and most important manufacturing processes for the production of components in almost every industrial sector.Since the Middle Ages, this process is being continuously developed and adapted to the changing needs.The cutting technology, however, brings the producers to the limits of the technical transability, particularly with regard to small and very small components. Tool wear, tool life, machining forces and heat affected zone became a limiting factor. But now the laser experts from GFH GmbH raise this manufacturing method to a new level:The conventional turning tool is replaced by a contactless laser that evaporates the material with ultra-short laser pulses.This technology has been integrated from the GFH into a specially designed production machine. The process-related technology disadvantage of the lower removal volume per unit compared to the cutting process is eliminated by the double-spindle concept. The GL.smart equipped with this technology, in conjunction with the integrated CAD / CAM solutions, represents the next milestone in the history of turning.

"Rotosymmetrical components are in the course of miniaturization even smaller and more sophisticated," reports Florian Lendner, CEO of GFH GmbH. “This is where conventional manufacturing technologies reach their limits, because the cutting forces, that act on the component and the tool size, make machining more difficult and even make it impossible with particularly sensitive geometries. This is especially true when materials are needed that are considered difficult to machine.” Several years ago, GFH GmbH therefore demonstrated the possibility of turning and grinding with lasers on its universal laser micromachining systems and delivered the first productive solutions. However, the full potential of the new manufacturing technology could be only partially exploited because the machines were not designed for these applications. There were limitations, for example, in terms of the speed of rotation of the components, the efficient use of laser radiation and generally the complete workflow. These limitations has been eliminated with the new machine: "After several years of intensive development work together with reference customers and supported by European research funding as part of the Horizon 2020 project, we can proudly present our new turning and grinding solution," reported Lendner. “It is available as a double spindle in short and / or long turning design, optionally with a rotating swivel unit as a counter spindle. This means there are no limits to the complexity of the components, and even end machining is possible.”

All-round talent for rotationally symmetrical precision components

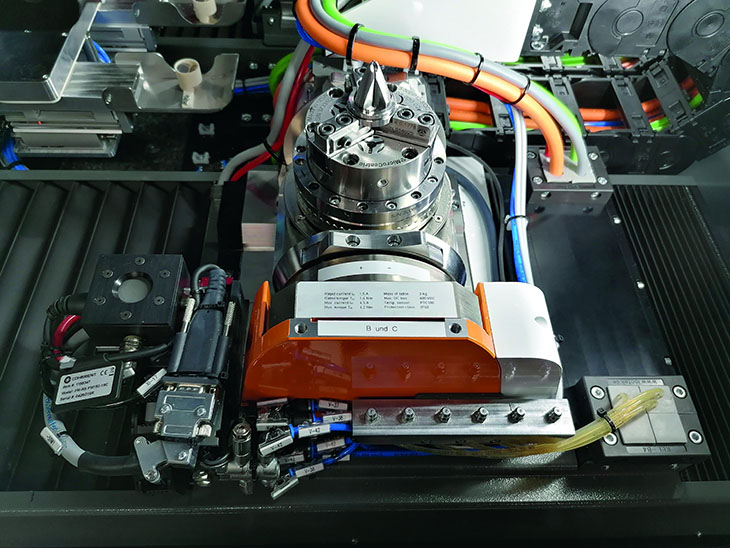

In addition to pure turning and grinding processes, the machine is also able to perform drilling, cutting and engraving operations - without any remodeling work. This makes the GL.smart an all-round talent for rotationally symmetrical precision components. A key factor is the combination of high process speed with absolute precision. For this purpose, the air-bearing main spindle is accelerated a torque drive in a position-controlled manner up to 3500 rpm within 0.4 seconds. Radial and axial concentricity in the nanometer range enables production with grinding tolerances. A force-controlled tension collet system with wobble correction and automatic bar feed represents the interface to the component.

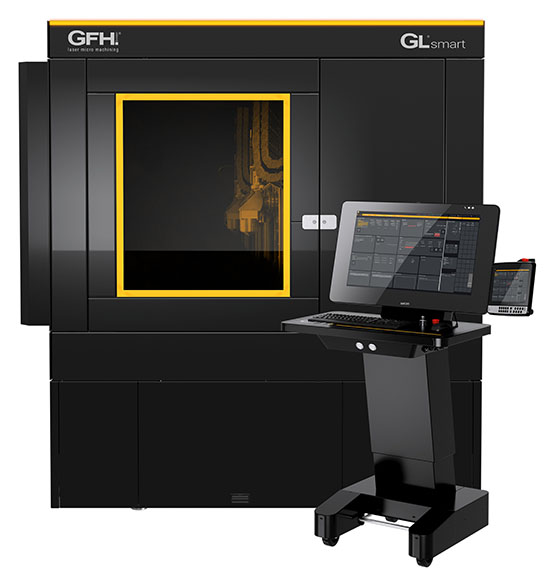

As the newest machine in the GL series, the GL.smart with dimensions of 2,212 mm x 1,026 mm x 2,320 mm (L x W x H) offers productivity in the smallest of space. In addition to its compact design, the system impresses with an innovative, black glass housing. This granted in addition to full protection against laser radiation, a safe shielding from X-rays that have been proven by test methods. By using high-power lasers in combination with beam splitting, simultaneous processing on two stations is possible, which means double output. "On request, the machine can also be equipped with a bar feeder as a loading unit. In combination with integrated component handling by means of robots we offer a fully automated solution for the 24/7 production of parts without restriction," explains Lendner. In addition, SPC and N.O.K. parts are kept separate and can be taken via robot without interruption of production.

Application fields of medical applications to watch industry

The applications of the new GL.smart are diverse and range from medical technology for the production of micro tools such as tweezers, micro blades or implants to the watch industry for the manufacture of so-called pivots, which are installed in the clockwork. The advantages of laser processing are, on the one hand, the attractive production times, which can be achieved thanks to the roughing and finishing process using ultra-short pulse lasers. In a first step, as much material as possible is removed by roughing with a high energy input. For the finishing, the final quality is achieved in the finishing process with less energy. On the other hand, almost any material can be used for non-contact, wear-free machining of even the smallest components.

Laser turning enables unusually high accuracy, particularly in the manufacture and processing of precision parts, so that other, more complex processes such as conventional grinding or roller burnishing can be saved, explains Lendner. “Thanks to the non-contact removal, the workpiece remains free of force and deformation during the entire machining time. This means that there is no loss of accuracy even with very thin and delicate components.” In this way, also parts with a large length can be easily machined.

Control software based on more than twenty years of process experience

The systems can also be freely programmed and controlled using the GL.control software, also developed by GFH, based on software process know-how from more than twenty years. "Thanks to our own software development and daily use in-house, GL.control is in a constant process of improvement and further development," says Lendner. "The intuitive and simple operating concept, the integration of the CAD-CAM functions as well as the complete integration of all subsystems, such as the laser, scanner or drilling optics make it easier for the user to operate the machine true to the motto 'only one software to control everything'. "

The PLC of GL.smart, is the fastest CNC control on the market and has been specially designed for laser processing in a development process for more than ten years. This control offers real-time access for the laser control, so that the laser can be switched on with an accuracy of 40 nm at full dynamic of the axes. "Thus, the GL.smart not only convinces with its very compact and innovative design, it also combines precision, flexibility and productivity in an attractively priced laser system that leaves nothing to be desired."

Further information at: www.gfh-gmbh.de

Contact partner: Florian Lendner (CEO)