With two live sessions from 27 to 28 April 2021, the press manufacturer presents its latest solutions for the digitization of forming technology

Göppingen, April 14, 2021 – For the international sheet metal working industry, the trade fair EuroBLECH has launched a Digital Innovation Series. Schuler will take part in the first event from 27 to 28 April with two live sessions. Here, the press manufacturer is going to present its latest solutions for the digitization of forming technology. Those interested can register free of charge for the online presentations and ask questions afterwards. Schuler's experts will also be available for discussions at a virtual booth.

In the first live presentation, Dr. Robert Vollmer from Schuler and Dr. Timo Böhm from Porsche, project manager at the Smart Press Shop GmbH & Co. KG, will show how to increase efficiency due to continuous material and part tracking. In their joint venture Smart Press Shop, Porsche and Schuler are integrating a continuous track & trace system for seamless body part tracking. Parallel to the development of machine, tool and material technology, the quality requirements for car body parts are steadily increasing. Due to forming limits of lightweight materials and sophisticated component designs, the process windows for producing good parts are often very small. Frequently, startup effects until continuous production, fluctuations in material quality or tolerances in the die cause problems and the production of scrap parts.

Complete transparency in production thanks to Track & Trace

Thanks to continuous part tracking in the press shop using Schuler Track & Trace, the gap to complete transparency in production is closed. Each individual part is labeled with a unique identifier and tracked during the production process. All data and information are linked and put into context. Data on the processed primary material (coil), measurement and process values in the blanking machine and the press line as well as quality characteristics through automatic or manual control devices are recorded.

The resulting closed quality control loop facilitates production optimization. Defects can be identified more quickly and eliminated in a target-oriented manner. Through open interfaces to MES systems or cloud platforms, the use of artificial intelligence tools in the field of machine learning is possible to monitor and control production in a supportive manner. Even if the developments here are at the beginning, approaches are already being pursued to optimize the re-oiling of blanks and adaptive control of the drawing cushion, in order to reduce classic component failures such as cracks.

Fully digitalized servo press supplied in only one year

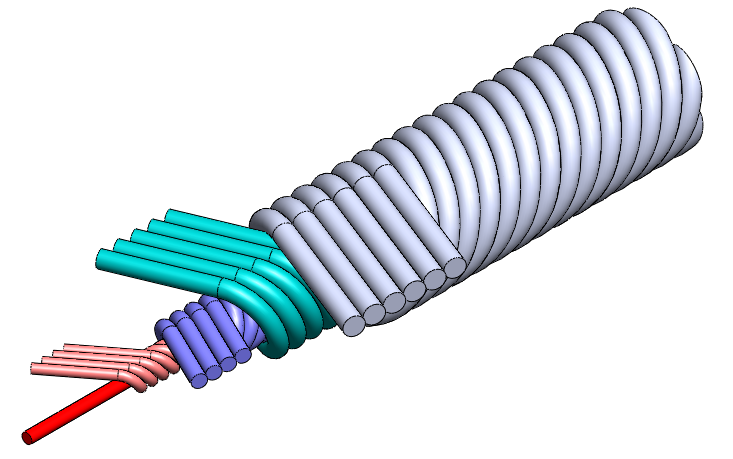

In the second live session, Schuler’s Ralf Schweitzer will talk about a fully digitalized 2000 ton servo transfer press which has been supplied and handed over for production in the record time of only about a year. It also features several of the latest solutions from the manufacturer’s Digital Suite. They will not only allow a safe operation of the press and a high Overall Equipment Efficiency (OEE) thanks to production monitoring or cooling analytics, but also enable real time access to process and machine data anytime, anywhere.

Additionally, Schuler’s Visual Die Protection system is used to prevent costly die damage and expensive follow-up costs by detecting causes of trouble and stopping the press before damage occurs. The offline programming and simulation software DigiSim® can be used to optimize the movement of press and transfer before the dies are set up. This allows a very quick, collision free and easy adaption of all existing dies to secure production.