Pioneering a path towards sustainable packaging solutions

How it all started: desperation leads to innovation

Like visionaries who have gone before him, the impulse for conTeyor founder Jos van Bree to invent a returnable packaging solution out of his garage 25 years ago was born out of necessity. While working at an automotive factory, he noticed a huge amount of packaging material was disposed of after a single use. Realizing that there was simply too much waste in the world, his mission was to change that.

The company has come a long way from its beginnings in 1995. Today, conTeyor provides bespoke packaging solutions for the automotive industry and is the supplier of choice for Europe’s leading automotive manufacturers. Its solutions, which include technical textiles, thermoformed products, plastic boxes and steel racks, ensure that bulky car parts like bumpers and door panels are transported from suppliers to OEMs and their Tiers safely, efficiently and with the highest cube (m³) optimization in the market. Custom-made for every new car model and reusable during its entire production cycle, it provides an attractive alternative to disposable packaging and offer automotive companies environmentally friendly, cost-effective and lean packaging solutions.

Gearing up for a greener future

Sustainability is high on the agenda in the automotive sector, and industry players are proactively reducing emissions and greening their operations which applies to everything from production to packaging needs. Innovation and sustainability have been embedded in conTeyor’s DNA since day one and has driven the organization to develop truly unique and sustainable packaging products and services--all in a closed transport loop. Just to mention a few of its novel approaches: its reusable modular rack and its nesting software ‘Nestimator’ which increases cubic meters by a quarter and embracing a circular economy.

Modular racks: re-usable and returnable packaging systems

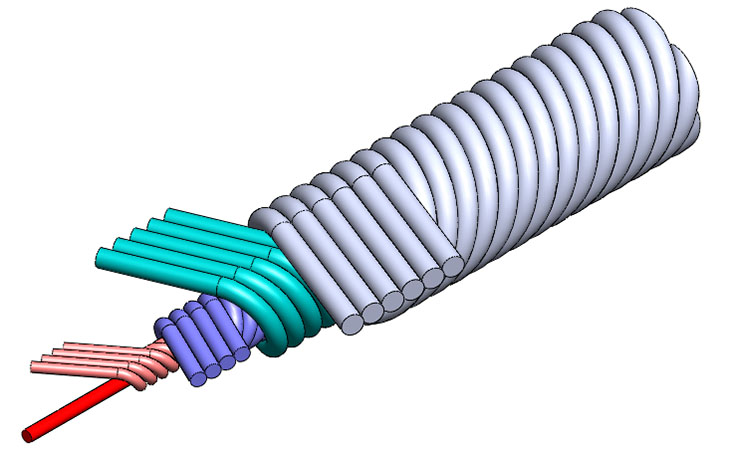

For most packaging solutions, end of life usually means that it cannot be re-used. Not so with conTeyor’s modular racks. This solution consists of a soft interior which is a set of textile pockets and the dunnage is mounted in an exterior plastic or steel rack which always stays the same. Irrespective of the products or their size, the customer has the same core rack which can be tailored to fit variable products using the internal textile pockets and dunnage. So, instead of buying 100 racks of a certain size for each specific component, customers buy 10,000 standard racks of one size. This extends the lifetime of the rack two to three times!

Nesting packs a punch

To achieve maximum packing density, conTeyor will nest the parts to fit closer into each other: not only side by side, but also top to bottom. Ingeniously, it optimizes cubic meter use to the maximum.

House of Competences

Aside from innovative products which include steel racks, plastic boxes and textile solutions, conTeyor offer three services: Delegated engineering refers to the project responsibility of a Customer Solution Manager (CSM) from early design to final delivery of a packaging solution. “Packaging as a service” provides a financial solution (rental or leasing) for companies that want to invest in innovation or the ‘track & trace’ solution which allows a company to optimize its supply chain by gaining visibility of the fleet location of its conTeyor boxes. And ‘Program Management’ offers OEM or Tier One partners an entire package of solutions around a particular portfolio.

conTeyor’s solutions tick all the ‘efficiency’ boxes

With a focus on sustainable development and green economics, efficiency underpins all of its different solutions. Whether it is textile dividers or Ecoboxes, rather than packaging parts separately, they are placed in pouches and the entire rack is transported to the factory, put on an assembly line then placed on a transport truck. This continuous back and forth of its returnable racks to the OEM to the supplier is referred to as a ‘closed loop’.

Ecopack KIT: thinking inside the box

The latest product, the Ecopack KIT, encompasses twin-sheet technology (a lower pallet and upper lid with a sleeve in the middle). This is an extremely light, strong and durable product. A few years ago, steel-only racks were mainstream, but they are gradually being replaced with plastic due to improved ergonomics, weight and recyclability. Such a solution typically lasts 10 to 15 years, even longer if the sleeve is replaced.

Coming full circle: recycling waste back into production

This brings us back to conTeyor’s founder’s primary mission to design out waste, keep products and materials in use, and regenerate and repair at the end of life to develop a truly circular economy.

CONTEYOR AT A GLANCE

Mission: Like no packaging

conTeyor’s tagline is like no packaging. Depending on how it is interpreted, one can take it as ‘we like no packaging’ or by implementing returnable packaging systems, its solutions are ‘like no packaging’. How? By achieving packing density. More parts per cubic meter equals less transport. Optimizing the entire supply chain leads to more value, lower costs and a reduced carbon footprint.

The big picture: Facts & Figures

Headquartered in Belgium, conTeyor is an international player in the development and supply of reusable packaging solutions for delicate manufacturing parts. Since 1995, conTeyor has been developing and producing patented sustainable solutions in textiles, plastic and steel for the automotive sector. In the past few years it has been developing its business in other sectors, such as the white goods, medical, electronic and aeronautic sector.

Present in 34 countries across Europe, the United States and South America, conTeyor co-locates manufacturing and offices on the same continents to keep the ecological footprint as small as possible. With 700 employees worldwide, 90 engineers design approximately 4,000 concepts a year and release about 200 projects a month.

What sets conTeyor apart?

One Global Footprint - same people, structure, ERP system and quality worldwide.

One House of Competences – Flexible services customized to each customer.

One Standard – all of its solutions can be standardized.