Productivity from a single provider: Modular automation concepts in combination with machining centers and digital services of SW.

Waldmössingen, 08/10/2021: From electric cars to medical implants: Catch-up effects after the pandemic have left many companies facing the challenge of quickly ramping up their production capacities. Schwäbische Werkzeugmaschinen GmbH (SW) will be presenting solutions designed for highly productive manufacturing solutions, for rapid scaling of quantities with low space and energy requirements at EMO 2021 in Milan in Hall 4, stand D01.

Many standard medical procedures were postponed during the pandemic and they must now be made up. This has given rise to an enormous need for implants made of titanium alloys and other alloys. Manufacturers can quickly increase their quantities with the BA W02-22i two-spindle machining center with linear and torque motors and integrated automation. On just four square meters of installation area they can manufacture complex workpieces with maximum precision. The direct drives in the feed axes ensure positioning accuracy even at the highest possible machining speeds with a guaranteed deviation of less than 0.006 mm.

SW will present a fully automated independent manufacturing cell live at EMO

BA W02-22i. The loading module with integrated 6-axis robot and pallet storage is already mounted on the machine when delivered. "With the independent cell, manufacturers can shorten startup times and increase their quantities by a factor of two immediately," underscores Andreas Kienzle, Key Account Manager for Medical Technology. Together with the MobileRob (MR), SW also offers an Automated Guided Vehicle (AGV) that changes the pallet storage cassettes without any manual intervention. It fills up storage with new raw parts and moves the machined, finished workpieces automatically to the station in manufacturing designated for them. "This allows manufacturers to increase their capacity several times over with minimal use of personnel or even unsupervised shifts, without any additional engineering expenses for automation," emphasizes Kienzle.

New components for e-mobility

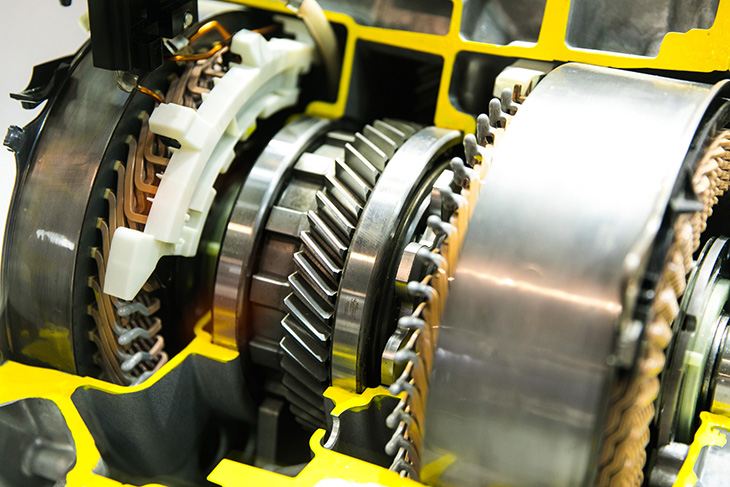

Demand for electric and hybrid cars in the automotive industry has risen dramatically. Suppliers have to boost their capacities for manufacturing new components. With independent manufacturing cells based on the BA W06-22 with integrated automation, SW is demonstrating a highly productive solution at EMO 2021. It allows users to machine workpieces made of non-magnetic materials such as aluminum or titanium alloys in a working area of 600x630x510 mm for single-spindle and two-spindle machining. SW offers manufacturers a feed rate of up to 120m/min and therefore the shortest possible cycle times.

The SW TopRob loads and unloads the BA W06-22 from above. The loading unit is modularly expandable. The AGV MobileRob automatically fills up the storage tower with raw parts without the use of personnel and moves the machined, finished parts to freely definable locations in the plant. An important advantage for users is the significantly better energy efficiency of multi-spindle machines in comparison to single-spindle machines. "In this way suppliers can meet the requirements of OEMs for a lighter CO2 rucksack of their vehicles," emphasizes Jörg Schmauder, Managing Director of Sales and Marketing.

Metal cutting of large structural parts such as battery cases represents a special challenge for suppliers. Until now, manufacturers have produced these components made of non-magnetic materials on existing machines, which are not optimally suited for this purpose. With the new BA W08 series single-station machine, SW now offers an expanded range for machining large workpieces for 4- and 5-axis machining. Direct drives in all axes shorten cycle times and boost productivity. Structurally, a monoblock and box-in-box design ensure maximum precision. SW offers custom-made and modularly expandable automation solutions for quickly increasing capacity for this series as well.

life services – productivity for the life of the machine

The term "life services" for SW incorporates all service related to the life cycle of manufacturing solutions. Customers benefit from the tailor-made advantages for practical applications: from employee training and startup to analysis of machine data, the hotline and field service including delivery of spare parts, and on to retrofitting of older machines.

An important part of the services is "Life Data": Using software solutions developed internally by SW, the status of the machine, manufacturing systems and components are made transparent and can be analyzed. The core element of Life Data is the switch cabinet installed in the IoT gateway, which is used to send relevant data.

Using the SW CloudPlatform (SWCP), the customer is able to analyze the status of systems in terms of condition monitoring. This also supports SW Services for rapid and optimum response speed if a service call is needed. The SW ScadaPlatform (SWSP) integrated into the customer network helps the customer trace components and monitor lines for general purposes. Connections to already existing customer systems such as ERP or MES systems are also no problem for SW with product type SWMP API.