Innovation and progress make the Italian group stand out at Fakuma 2021 (hall B2, stand 2207)

Friedrichshafen, 12-16 October 2021 - Technology, sustainability, progress. Sirmax Group showcases a series of innovative, high-tech products at Fakuma 2021. The Italian company, based in Cittadella (near Padua), specializes in the production of polypropylene compounds, post-consumer compounds, and bio-compounds for a variety of applications. It has now developed extremely high-performance green product families. Alongside its traditional "core" production, the Italian group has been able to produce enhanced plastic deriving from the mechanical recycling of post-consumer waste, making it usable as a durable good. This has been possible thanks to decades of experience and to the work of five Research Centers. The Group also offers molding solutions that reduce the use of virgin plastic, and produces 100% biodegradable and compostable bio-compounds.

“We did not stop during the year of the pandemic," explains Massimo Pavin, president & CEO of Sirmax Group, "we did not stop investing, innovating or delivering quality products. We put a lot of focus on sustainability, in compliance with all ESG criteria, by bringing innovative products to the market. We continued to invest cautiously, favoring financial stability and working on consolidating our skills. Our speed and reliability allowed us to acquire new market shares. Our regionalized and certified supply chains, together with our technology and organization – an approach we call 'Proximity Compounding' – meant we were always close to our clients."

GREEN ISO®: A new lease of life for post-consumer plastic

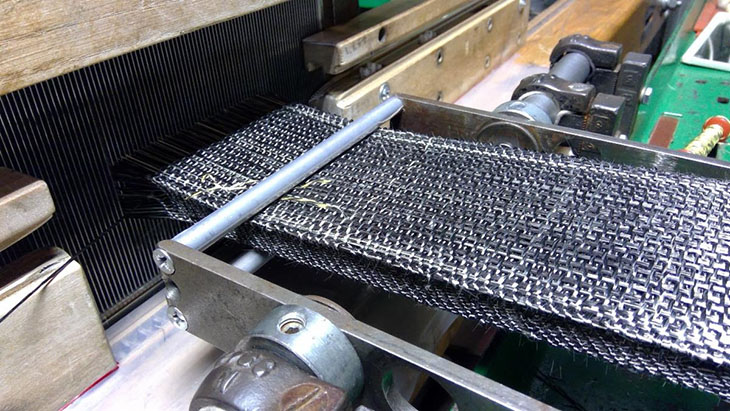

Sirmax Group elevates post-consumer plastic to create products that can be used to create durable goods and high-performance automotive components, despite coming from waste. Sirmax's added value lies in the plastic enhancement process. The company's recycled compounds are enriched with mechanical and technical capabilities: Granules are combined with glass fiber, talc or other components, making the material just as resistant, performing and reliable as virgin plastic. This little “miracle” happens thanks to the Green ISO family. This family includes Green ISOFIL, Sirmax's polypropylene compound that can be made of up to 100% post-consumer resin depending on its final application. This excellent compound stands out for its ability to adapt to aesthetic and design applications.

Other compounds in this family include Green ISOGLASS, which is produced in the same way as Green ISOFIL but has different mechanical characteristics that lend themselves to structural automotive components; Green ISOTER, an ABS technopolymer made from pre-consumer recycled material used for technical and aesthetic applications – mainly in the electrical/electronic industry (e.g., electric wall plates) – which can be finished with a marble effect that recalls its recycled content; Green ISOCLEAR, a polycarbonate technopolymer with pre-consumer material content, which can be produced in white, among other colors, and is used for technical applications in the electrical/electronic industry.

Smart Mold, innovative molding solutions

Smart Mold, Sirmax Group's flagship brand, is an engineering company started by the University of Padua. Sirmax acquired 50% of the shares following a capital increase in 2020. Smart Mold has two business activities. Its first, most innovative activity is to facilitate the processing of recycled plastics. The company has patented a surface treatment for the molds used for plastic injection, which makes filling molds easier by decreasing injection pressure. By their very nature, recycled materials have a higher and more variable viscosity than virgin materials, which limits their use. The Smart Mold patent, however, opens up new possibilities for post-consumer plastics, with a lower environmental impact.

Smart Mold's second business activity focuses on reducing plastic consumption within a product by using raw materials with a higher added value. Smart Mold supports companies from the engineering design stage of the product, studying its applications (for example, the internal structure of a car dashboard) and the mechanical characteristics it requires (e.g. withstanding loads and shocks). It then uses advanced software to simulate the product's mechanical behavior and recommends design solutions to reduce its weight and the amount of plastic used. Thanks to its expertise, Sirmax is able to provide optimized materials for each application, accurately profiled for the required engineering process. By combining Sirmax's most performing materials and Smart Mold's surface treatments, the thickness of many structural components can be significantly reduced, leading to a reduction in weight and in the consumption of virgin plastic.

Sirmax's 100% biodegradable and compostable bio-compound

Sirmax Group has developed BIOCOMP®, an innovative family of bioplastics obtained from both renewable and fossil raw materials. It is produced as granules using known technologies for the transformation of plastic materials, which have been specifically adapted to treat biodegradable and compostable polymers. These granules can be used to make products with similar or even improved characteristics compared to traditional plastics. Unlike traditional plastics, however, they are completely biodegradable and compostable as required by the EN 13432 standard.

BIOCOMP finds many applications in the flexible and rigid packaging sector, from large-scale distribution to the agri-food sector, catering, and disposable packaging for varied uses. Its use is therefore not limited to takeaway bags, but also includes compostable packaging for mozzarella and ice cream, general packaging for solid and liquid foods, refrigerator bags, laminated paper packaging for the sausage industry, packaging and accessories for clothing and fashion items. It also extends to the production of plates, glasses, trays and cutlery for the hospitality sector, freezer and ice cubes bags, and photo-selective mulching sheets.

Sirmax's products contribute to CO2 reduction

Sirmax Group produces compounds that contribute to the reduction of CO2 emissions, as shown by a Life Cycle Assessment (LCA) study carried out by Spinlife, a company of the University of Padua. The study focused on two polypropylene compounds intended for the automotive and household appliance sectors: Isofil®, produced from virgin polypropylene, and Green Isofil®, containing 33.8% Serplene®, a post-consumer recycled plastic material produced by SER, a Sirmax Group company. Both products are mixed with mineral fillers, coloring masterbatches and other additives in different percentages. Different impact categories were examined: The protection of human health and ecosystems in relation to the extraction of minerals and fossil fuels, the potential impact of acidifying substances on air and soil, the depletion of stratospheric ozone, the climate change linked to greenhouse gas emissions, the impact on the environment from the emission of nutrients into the air (nitrification), photo-oxidant formation, and quantification of the potential for deprivation of water resources.

The main findings that emerged from the data show that the production of raw materials has the most significant impact on all environmental categories. This impact is, to a lesser but still significant extent, determined by energy consumption. It is essential to note that post-consumer recycled polypropylene reduces the impact on almost all the categories considered. The analysis of some Green Isofil families shows that replacing virgin polypropylene with post-consumer recycled material can, in many cases, halve carbon dioxide emissions. Furthermore, waste transport does not have a significant impact, confirming the validity of the chosen model.

Sirmax's values: Sustainability, Proximity, and a focus on people

Sirmax Group has a sustainable approach to business. Sustainability informs our production processes, our relationships along the supply chain, the development of codes of conduct, and our adoption of management practices that focus on responsibility. Of course, it is also the basis for our products: High-performance circular compounds and bio-compounds.

Our excellence is rooted in the idea of Proximity, and we are able to offer solutions that put customization at the center of each project. Proximity means total closeness to our clients, empathy, and a shared purpose. It also means being in tune with the market by predicting trends and creating increasingly performing compounds. It means being in tune with the environment, safeguarding it through our products and services. It means being close to the end consumer, with local supply chains that ensure fewer costs and higher time savings.

Sirmax Group loves teamwork, believes in young people, invests in training, builds relationships with universities, and consolidates skills by promoting internal mobility. We believe in a “horizontal”, open, and creative business model. This is our true strength. The people who make Sirmax Group have shown great strength and resilience during the months of the pandemic. This is the result of a company policy that puts people first.