High grade purity despite impurities: Innovative complete plant with three operating modes safely filters recycled aluminium from difficult input material.

Circumspect, temperature-reduced processing prevents ignition and explosion

According to statistics from the German industrial credit bank AG (IKB), global production of primary aluminium increased by 3.1 per cent to 65.3 million tonnes in 2020. In addition, around 11.8 million tonnes of the light metal were recycled. Especially in the case aluminium scrap, grade purity plays a major role for subsequent processability. In order to be able to sell the purest material possible on to aluminium processing companies, and thus most profitably, an Austrian company needed new equipment for crushing and separating different input materials. The challenge: The aluminium dust and aluminium alloys with magnesium admixtures produced during the crushing process are highly flammable, so there is an acute risk of fire and explosion in the plant. To ensure the safety of the machines and the employees at all times, the company cooperated with Erdwich Zerkleinerungs-Systeme GmbH. The experienced company from Igling in Bavaria implements a special plant concept that not only enables an almost sort-pure separation of the materials, but also allows three different operating modes for the most flexible processing possible.

Metals are currently among the most sought-after raw materials worldwide: the price of aluminium alone has risen from around USD 1,620/t to more than USD 2,550/t within the year from the beginning of July 2020. The advantage of aluminium is that the metal can be melted down almost as often as desired and processed into various products. Moreover, only 5 per cent of the energy required for the production of primary aluminium must be used for the recycling of aluminium scrap. But in order for processing companies such as car manufacturers or producers of electronic goods and packaging materials to buy the raw material at the required prices, the recycling companies have to supply material that is as pure as possible so that it can be melted down and processed further without delay.

High grade purity demands require a new type of plant concept

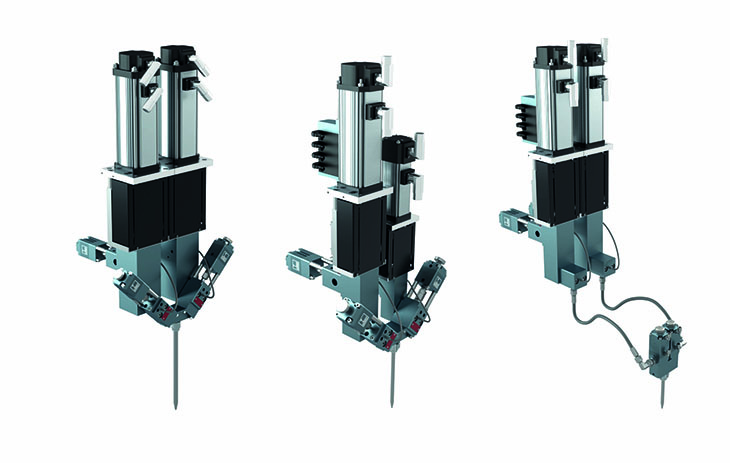

Until a few years ago, an Austrian company used an ordinary twin-shaft shredder for shredding. However, machine breakages and blockages occurred at regular intervals, causing a considerably negative impact on the operating process. In 2017, therefore, a first step was made in looking for a replacement for the shredding plant. After extensive consultation with Erdwich, those responsible decided to install the RM1350 ripper. The main advantage of this twin-shaft ripper developed by Erdwich, compared to the shredder used previously, is that the blades do not simply shred the input material, but literally tear it apart due to their special shape. This allows the plant to grip the aluminium scrap far better and there are fewer blockages or damage to the machine.

However, as the metal processing companies increasingly demanded pure, unmixed recycling materials, the management decided in 2019 to optimise the entire plant concept with regard to the processing of aluminium scrap. For the implementation, the company again commissioned the experts for shredding systems from Erdwich due to their good experience with the twin-shaft shredder. This time, however, a single machine was not enough: In order to be able to react as flexibly as possible to the variety of input materials, the Igling based company planned and implemented a complete plant concept into which the existing twin-shaft shredder was integrated. The shredding plant was supplemented by a hammer mill also developed by Erdwich. Several challenges had to be resolved simultaneously. "For one thing, the space available for the plant was limited to a very narrow, half-open hall, which required planning with centimetre precision and foresight," explained Harald Erdwich, Managing Director of Erdwich Zerkleinerungs-Systeme GmbH. "On the other hand, the input material consists in part of undefinable components such as non-metallic impurities or even solid iron parts, which made sorting difficult. Therefore, it was necessary to implement several processes and the corresponding equipment to separate different materials and alloys."

Three different operating modes for different input materials

While ultra-fine materials such as sand or dirt particles are sorted out by a vibrating screen, a magnetic drum separator ensures that FE parts are removed from the shredded aluminium scrap using magnetic technology. A zigzag air separator also separates foil or wood particles from the metallic components; an eddy current separator is responsible for filtering out plastic parts. For impure alloys, a fourfold sorting device is also provided, which works, among other methods, by means of X-ray detection. This makes it possible to achieve a particularly fine separation of the material and thus a high degree of grade purity.

But the input fractions are not always composed in the same way. In order to be able to react more flexibly, Erdwich therefore implemented a hitherto unique concept: three different modes can be set for the efficient processing of the material. "In mode A, the aluminium scrap is fed directly into the RM1350 pre-shredder by means of a gripper or stacker and then re-shredded by means of our HA800 hammer mill," Erdwich reports. "The mixed fractions are separated using various sorting techniques and then discharged into containers provided by the customer." Mode B enables the faster processing of pure aluminium scrap. After shredding in the twin-shaft shredder, a separation of FE and V2A material is carried out by means of a double magnetic stage; the discharge takes place by means of a swivelling conveyer belt into the containers provided.

Double feeding enables parallel processing of different input fractions

Mode C provides a special feature: In order to be able to process input materials made up of different compositions simultaneously, this mode allows double feeding. This makes it possible to process both pure aluminium scrap, as in mode B, and aluminium/copper cast material in parallel. The latter is fed via the mobile conveyor belt into the vibrating feeder, crushed by a hammer mill and then separated by means of X-ray sorting and transported into containers. The different modes can be selected on the operator panel by means of a softkey before the system is started. Depending on the composition of the material and the mode, a throughput of up to 2,500 kg/h can be achieved.

Circumspect shredding technology and sensors prevent ignitable dust concentrations

"However, the shredding process for aluminium scrap in particular must be constantly monitored," said Erdwich. "Because as soon as aluminium is shredded to less than 4 mm or the input material contains aluminium alloys with magnesium components, it can ignite and trigger an explosion." In the case of aluminium dust, for example, even a concentration of 50 g/m3 is sufficient to create an ignitable air concentration. If there are magnesium admixtures, the material reacts even more sensitively: here, the mere frictional energy can trigger spontaneous combustion. "Thus, to avoid accidents, the cutting mechanism geometry of the ripper is designed in such a way that the material is shredded as gently as possible under temperature-reduced conditions," Erdwich explained. "Sensors also ensure that no excessive dust concentration can occur inside the hammer mill if, for example, there is a filter defect or other failure of the extraction/filter system."

After crushing with the hammer mill, the output fractions are only about 70 mm in size, so that the material can be easily transported and subsequently melted down again. Any changes in the composition of the input material are no problem, because the three different operating modes and the innovative sorting techniques also allow other types of scrap to be processed carefully. There is no need to worry about clogging or machine breakage. With the system completely planned and realised by Erdwich, the company is optimally equipped for the future and can easily and quickly adapt to new developments in scrap processing without having to put up with lengthy repairs and downtimes.

Further information is available on the Internet at: www.erdwich.com