3D printers may be popular with artists and hobbyists, but this technology is also quickly becoming one of the best tools for manufacturing across multiple industries. That utility also extends to low Earth orbit, where astronauts spend their time on the International Space Station. Here are some benefits of 3D printing in space.

Getting Off the Ground

3D printing in space starts with getting off the ground and escaping Earth’s gravity. Traditionally constructed rockets are assembled piece by piece, but new technology allows manufacturers to rely more heavily on additive manufacturing as they work to reach the stars.

Relativity Space, a new space tech startup, is working on a fully 3D-printed rocket. It can’t carry massive payloads, but it may be ideal for small launches under 1,250 kilograms (2,755 pounds). These 3D printed rockets are ready to go, from start to finish, in 60 days and have as many as 100 times fewer parts than traditional rockets. For comparison, a Falcon 9 might be reusable, but it can take up to 18 months to build a new one.

Reducing Launch Weight

A lot of thought goes into getting something ready to head into orbit. Vibration testing is essential to ensure nothing will shake apart during the launch. All the seals need to keep atmospheric pressure and vacuum out, and it takes a significant amount of fuel to break free of Earth’s gravity and lift these massive constructs into orbit. The rocket must generate enough force to exceed the pull of gravity. The heavier the missile, the more difficult that becomes.

3D printing can help reduce launch weight in several ways. 3D-printed rockets are lighter by nature, requiring less fuel and force to escape Earth’s gravity. The cargo weight is also reduced because there’s no need to send individual tools or supplies into orbit. This, in turn, helps reduce the cost of each launch and the amount of fuel burned.

Restocking Supplies

Packing for a trip is always nerve-wracking. You can go over everything twice and still end up forgetting your toothbrush. Imagine how much more challenging that becomes when you can’t just run out to the corner store because you’re in orbit. Even the best-laid plans never survive contact with the vacuum of space. Astronauts might need something that no one thought to pack.

In 2014, ISS astronauts manufactured the first 3D printed object in space — a ratcheting wrench designed for a specific task. NASA engineers developed it on the ground and sent the specs to the space station for printing, eliminating the need for an extra rocket launch to bring them a single tool.

Recycling Waste

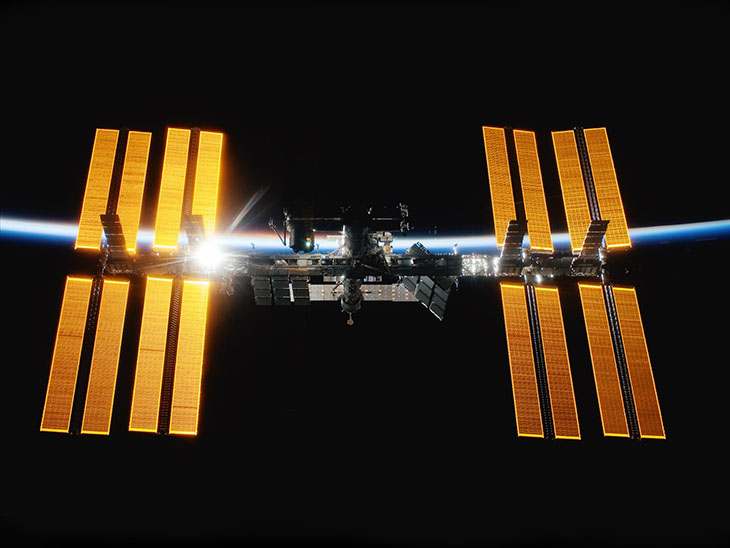

Space junk is a problem. Astronauts aren’t throwing their water bottles and freeze-dried ice cream wrappers out the nearest airlock, but they still use single-use plastics and generate trash while in orbit. Instead of having them bring it home, NASA devised another solution. Today, in addition to the 3D printer, the International Space Station is equipped with a device known as The Refabricator. Think of it as recycling in space. The Refabricator can take various plastic materials and break them down into feedstock or filament for the printer.

This reduces the amount of trash astronauts have to bring home and decreases how much 3D printing filament NASA or SpaceX needs to send to the space station. This, in turn, lowers costs and fuel consumption for resupply missions. 3D printing in space doesn’t need to weigh down a Cargo Dragon capsule.

Assisting Robots and Planetary Colonization

Mars is the only planet completely colonized by robots as of 2022, but it won’t stay that way forever. Unfortunately, it is also incredibly inhospitable to human life. Astronauts will need unique habitats to survive on the Martian surface. Humans can construct them, but sending 3D printing-capable robots to do the work is much easier.

Robots can already 3D print homes and structures here on Earth. Instead of laying down layers of plastic, they apply thin layers of cement, building up the walls one slice at a time. The same technology could be applied to Mars rovers, using naturally occurring materials on the red planet to build habitats for human colonists or explorers.

They would still need some tweaking once the astronauts arrive to ensure the structures are sealed against the harsh atmosphere, but imagine traveling hundreds of thousands of miles, only to find a house built and ready for you with the lights on, welcoming you to an alien planet? Colonizing Mars won’t be easy, but 3D printing could help make the red planet more hospitable.

3D Printing in Space

People have been dreaming of the stars for thousands of years. Technology has finally caught up with imagination, providing the tools necessary to explore the universe, one planet at a time. 3D printing isn’t the perfect solution to all the challenges facing human spaceflight in the coming years, but it will make it a little bit easier to look up at the stars and imagine being out there.