Electrical service is one of the most crucial considerations when planning an industrial facility. Whether you’re building a new structure or expanding an existing one, you must ensure it can reliably power any building systems and equipment within it. The more attention you give electrical systems design, the more cost-effective the facility will be.

The best way to approach designing electrical systems is to work with an experienced electrical engineering service. However, these third parties can offer more relevant help if you have a better understanding of your needs and goals. With that in mind, here’s everything you should consider when designing industrial electrical systems.

Determine Equipment’s Electrical Needs

The first step in electrical systems design is determining the facility’s power needs. Review the equipment the system will power, including their required voltages and amperage. Be sure to cover building systems like HVAC, too, as heating is typically the largest energy end use in commercial buildings but may be easier to overlook.

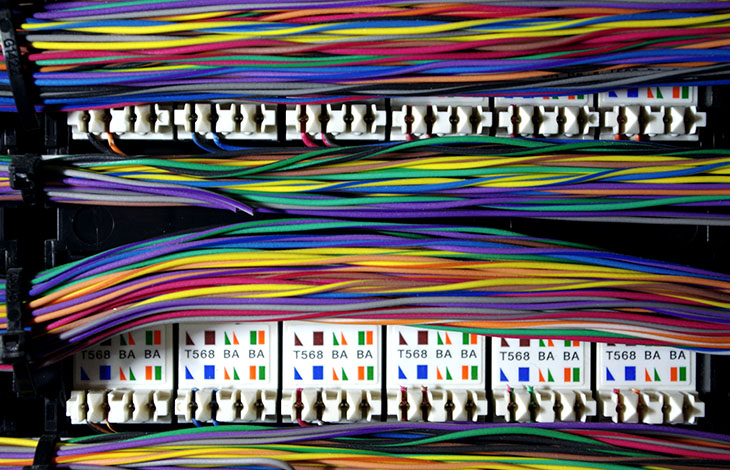

Some specialized equipment requires dedicated circuity. That includes IT racks, refrigerated systems and breakroom appliances. Keep a list of all these systems with unique needs so you can design separate circuits for them.

Choose a Power Source

It’s also important to consider where your electrical system will get its power. Utility-owned transformers and substations are the most common and obvious sources, but they’re not the only options. Many facilities are moving toward in-house renewable energy, which carries different requirements.

Unlike grid power, renewables don’t generate electricity at a consistent rate, and peak usage times often don’t align with peak generation with solar panels. Consequently, if a system uses renewables, it also needs an energy storage solution to account for these discrepancies. You must also ensure you set up enough renewable infrastructure to meet the facility’s voltage and current requirements.

Consider Physical Conditions and Limitations

Electrical systems design must also consider the facility’s physical environment. If it must cover a large area or transfer power across several floors, it may need multiple transformers and branch circuits. It’s also important to consider any size limitations, as you may need smaller equipment in a more cramped area.

The facility’s location and climate impact design best practices, too. Colder climates may require additional insulation, and running underground cables may be more difficult — requiring more time and higher budgets — in some areas.

Emphasize Efficient Distribution

It can be easy to overlook distribution specifics, focusing on mere voltage and amperage, but that’s a critical mistake. An effective electrical system is about more than just providing enough power. It must also distribute this energy efficiently. Consequently, you should review your distribution options to see how much equipment and what kind of circuits you need to ensure even, reliable coverage.

The most efficiently distributed system may incur extra hardware costs from additional transformers and dedicated circuits. That can be discouraging, but remember that electrical expenses are often lower when facilities have the most efficient system for their needs. Spending more upfront on a more efficient distribution system will pay for itself over time.

Design for Scalability

Another important electrical system design best practice is to leave room for growth. The system shouldn’t deliver too much above the facility’s needs, but it shouldn’t provide the bare minimum, either. Providing more voltage, amperage, ohms and distribution systems than you need will make the system more reliable and enable future growth.

Industrial facilities installed 384,000 robots in 2020, and experts predict that figure to rise yearly, reaching over 500 new installations in 2024. Internet of Things (IoT) growth shows similar trends. This rapid expansion means almost every manufacturer will likely have more electrical equipment in the future than they do today, so planning for easier scalability is crucial.

Ensure Backup Power

Industrial electrical systems must also include a backup power supply. Since the primary system involves so many considerations, these safeties can be easy to forget about. However, not installing backup generators and circuitry can be costly in an emergency.

As electrification rises, power outages translate into increasingly significant disruptions to your operations. Without a reliable backup system, you could experience several hours of lost productivity a year from power interruptions. In contrast, creating a backup system ensures you can remain productive and conserve sensitive resources amid a grid failure.

Review Codes and Standards

Finally, you must familiarize yourself with any applicable legal standards. The National Electric Code (NEC) provides a baseline for businesses across the U.S., but electric codes vary by state, including some going above NEC provisions or using an entirely different local system.

Contact state legal authorities to learn more about what standards apply to your facility. When working with an engineering service, ensure they understand these requirements and have the appropriate certifications to work in your area.

Electrical Systems Design Is Crucial to Get Right

As the world moves away from fossil fuels, electrical systems are becoming increasingly central to a business’s operations. Amid that shift, learning electrical systems design best practices becomes all the more important.

When you understand these design considerations, you can work more effectively with engineering firms. You’ll then ensure your facility has the most efficient and reliable electrical system for its unique needs.