High-speed machining (HSM) is a pivotal advancement in the manufacturing industry, revolutionizing how materials, especially stainless steel, are processed. By significantly increasing cutting speeds and feed rates, HSM boosts productivity and enhances the precision of the final products.

This technique is particularly beneficial when working with stainless steel. The ability to efficiently and accurately machine this alloy opens up new manufacturing possibilities. It allows companies to meet the growing demand for high-quality components in aerospace, automotive and medical devices. Mastering high-speed machining techniques for stainless steel equips manufacturers with the tools to stay competitive in a rapidly evolving industry.

Understanding Stainless Steel and Its Challenges

Stainless steel is renowned in the manufacturing world for its exceptional strength, durability and resistance to corrosion. Specific grades are even suitable for food processing, thanks to their ability to maintain purity and resist bacteria accumulation.

However, machining stainless steel presents distinct challenges, particularly at high speed. Work hardening can occur, where the material becomes more rigid and resistant to further machining, leading to accelerated tool wear.

Moreover, the intense heat generated during high-speed machining can further exacerbate tool wear and negatively impact precision. Practical strategies for managing these challenges are crucial for maintaining efficiency and product quality.

Key Strategies for High-Speed Machining of Stainless Steel

Mastering high-speed machining for stainless steel requires a strategic approach to overcome common challenges. Here are strategies that empower professionals to achieve improved productivity and precision.

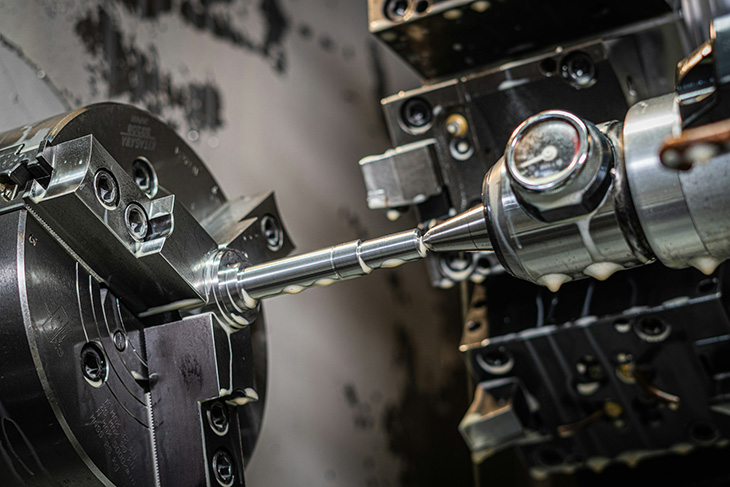

1. Tool Selection and Optimization

Selecting the optimal cutting tools is crucial for efficient high-speed stainless steel machining, as the right choices can withstand the rigors of high temperatures and abrasion. Materials — such as carbide, ceramics and coatings like titanium aluminum nitride — are highly advisable for their durability and heat resistance.

The tool’s geometry is pivotal in minimizing heat and enhancing chip evacuation, with a positive rake angle being particularly effective. This reduces cutting forces and heat generation, facilitating smoother cuts and extending the tool's life.

2. Machine Tool Considerations

A machine that combines adequate rigidity with a high-power spindle is essential for effective high-speed machining. This combination ensures it can handle the intense forces and temperatures, preventing deflection and inaccuracies. Milling spindles that reach speeds of up to 4,500 RPM are particularly suited for compact solutions. They offer a blend of speed and precision for smaller components.

Additionally, machines with high-speed tool changers reduce downtime between operations and enhance overall productivity. Integrating advanced software for precise control further optimizes the machining process. It allows tighter tolerances and superior surface finishes, critical in high-quality manufacturing environments.

3. Optimizing Cutting Parameters

Adjusting cutting speed, feed rate and depth of cut is vital for achieving optimal performance in high-speed machining, especially when working with materials like stainless steel. Starting with the manufacturer’s recommendations provides a solid foundation, as these guidelines are based on extensive testing and expertise.

From there, fine-tuning these parameters for specific applications allows manufacturers to tailor the machining process to the unique characteristics of each workpiece and operation. This customization is crucial for finding the perfect balance between cutting speed and tool life.

Pushing the tool too hard can lead to premature wear, while being too conservative may result in inefficient machining. The goal is to achieve the highest possible efficiency without sacrificing the machined part's quality or the cutting tools' longevity.

4. Effective Cooling and Lubrication

Utilizing coolants and lubricants prevents overheating and reduces tool wear during high-speed stainless steel machining. These fluids dissipate heat and minimize friction between the cutting tool and the workpiece, significantly increasing tool life and allowing high cutting speeds and feed rates.

This improvement in performance leads to more efficient production runs and higher-quality finishes on parts. Options like high-pressure coolant systems and mist lubrication are particularly effective for high-speed stainless steel machining.

High-pressure coolants forcefully remove heat and chips from the cutting zone. At the same time, mist lubrication provides efficient cooling and lubrication with minimal fluid usage. These factors make them suitable for maintaining optimal cutting conditions and enhancing machining efficiency.

Implementing a Holistic Approach

Mastery in high-speed stainless steel machining demands a holistic approach that synergizes tool selection, cutting parameters, cooling techniques and the machine's capabilities. This comprehensive strategy ensures each element works harmoniously to maximize efficiency, precision and tool life.

Manufacturers must embrace continuous learning and remain open to adopting new technologies and techniques as high-speed machining evolves. By staying at the forefront of innovation, professionals can enhance operational efficiency and maintain a competitive edge in the rapidly advancing manufacturing landscape.