Automation is essential to success in today’s industry. At the same time, running multiple robots at once means it’s all the more challenging yet important to balance factory energy usage. Consequently, you must determine the ideal type of industrial power supply for your robotic equipment.

Delivering consistent electricity with minimal waste and costs is key to ensuring an effective automation rollout. You can make these choices with greater confidence when you understand how each type of power supply unit (PSU) serves different use cases.

Linear Power Supplies

The most basic solution is a linear power supply, which takes an alternating current, lowers it and converts it into a constant DC voltage. This streamlined design and consistent output mean lower costs and minimal frequency noise, but it also introduces some barriers.

Most notably, linear systems waste a considerable amount of energy as heat. They typically achieve just 60% efficiency, which is far from ideal for most industrial applications. Their bulky components, while simple, also require more space, taking up valuable factory room that could otherwise go to profit-driving machinery.

Given these constraints, linear PSUs are best for small, targeted use cases. Low-voltage robots or those sensitive to frequency shifts, in particular, can benefit from such solutions.

Switching Power Supplies

The opposite of a linear system is a switching or switched-mode power supply (SMPS). Instead of directly transforming voltages, an SMPS maintains consistent output by switching on and off. Not running continuously means it’s far more efficient.

Despite their complex operation, switching industrial PSUs are smaller. That can be a crucial advantage today, considering manufacturing rents have risen by almost 50% per square foot since 2020. It also leaves room for larger automated machinery, and the higher efficiency means they can power complicated equipment without excessive costs.

Of course, an SMPS has downsides of its own. The biggest is it produces more signal noise and has higher upfront costs. In many cases, the resulting savings make up for the expense, but it can still be a barrier for smaller operations.

Variable Power Supplies

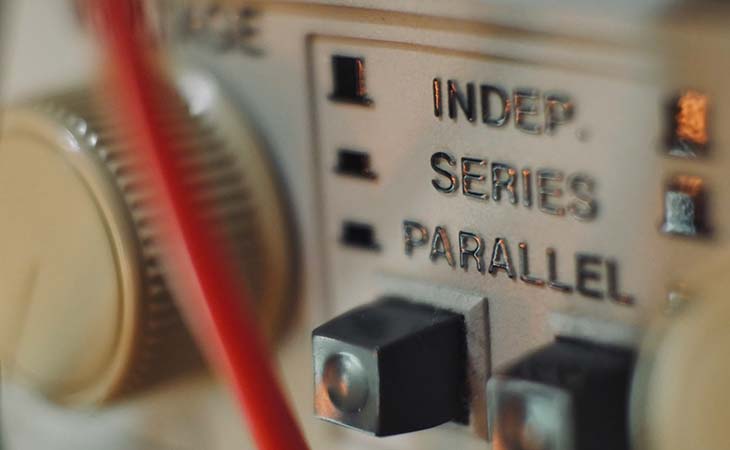

Many industrial power supplies — whether linear or switching — maintain a set voltage. However, you can also use variable systems, which give you the ability to adjust the output to meet a wider range of needs. Some even make these adjustments automatically.

The primary advantage here is you can ensure robots receive optimal electricity levels, regardless of input inconsistencies. That’s particularly important for sensitive machinery, as overvoltage can cause component malfunctions and complete shutdowns in extreme cases. Variable systems also promote scalability, as you can adjust the same PSU for a new machine instead of having to upgrade.

As you may expect from this relatively complicated setup, variable energy supplies are more expensive than some alternatives. Consequently, they’re best suited for a factory’s most sensitive or value-driving equipment.

Dual Power Supplies

Another less common but helpful type of power supply is a dual system. As the name implies, this equipment provides two separate outputs simultaneously. Usually, that means one positive and one negative voltage.

Like variable solutions, dual supplies are additionally complex and, thus, costlier than many alternatives. However, this complexity results in greater versatility. You can use a single PSU to power two robots or provide consistent efficiency to a bot with unusual power spikes.

Dual PSUs are best for machines with peak electrical needs far above their average baseline. Machining arms, drills and similar repetitive motion equipment typically fall into this category. Robots with unique amplification requirements tend to benefit from them, too.

How to Choose an Industrial Power Supply

Because each type of industrial power supply has unique advantages and disadvantages, there’s no single answer to which is the best option. The optimal solution depends on your needs. Consequently, you must determine your specific requirements before selecting a PSU.

Start with the robotic system you need to energize. Review its required voltage, wattage, peak demands and sensitivity to noise. Consider its size and price, too. A simpler, cheaper linear supply may be the most cost-effective if you don’t need much voltage or have high frequency concerns. Conversely, an SMPS will be better for a sophisticated machine or if energy efficiency is your largest concern.

Maintenance and usage considerations deserve attention, too. Almost three in four workers lack basic digital skills, so many manufacturing workplaces may struggle with more complicated equipment. An easier-to-operate system will offset this concern, but if you have enough tech talent, you may benefit from a variable or dual power supply.

You might need different solutions for varying robots. For example, you could use a linear supply for low-volume, high-sensitivity workflows while using a variable switching system for the rest. Hybrid approaches like this typically yield the best results.

Industrial Power Supplies Vary Widely

Choosing an industrial power supply is often a more complex decision than it seems. However, it’s an important process to get right.

Different solutions offer varying benefits, so it’s crucial to understand what you need and what equipment suits those demands. Learning about such differences is the first step to optimizing your robotic workflows.