Present on the market for only 14 years (since 1996 and 1999 in Europe and Poland respectively), the TCM Group (Tool Consulting & Management) has already gained recognition on four different continents.

A specialist in outsourcing, the company delivers tool management solutions to industry tycoons, including General Motors, Volkswagen or TRW. “We are a brand to rely on,” declares the TCM Poland Vice President, Mr Marek Polarski. It is thanks to Mr Polarski that “Manufacturing Journal” is now able to give you an exclusive close-up look at the TCM Service Centre in Polkowice, Lower Silesia.

Key Facts

Management at the TCM knows how to enter new markets successfully. A handful of key facts will testify to this. It was well before the business set up its Polish branch in February 1999 that the first substantial contract was waiting to be signed by its president. Hence in March 1999 a deal to provide tool management services was struck with a real automotive industry tycoon, Volkswagen Motor Poland, and more precisely with its Polkowice-based engine factory. “It was a real boost for our activity. We’ve been cooperating with Volkswagen for more that 11 years now,” Mr Polarski recalls. Two years later the TCM expanded in scope, taking over the TRW SSP factory in Czechowice-Dziedzice, Upper Silesia. The market growing rapidly facilitated the decision to open a service centre in Poland. Completed in 2003 in Polkowice, the centre has been used ever since as a base for tool management business run in the whole of the country. The expected results came soon, the group thus being able to win subsequent and substantial contracts. The TCM began to service Sanden Manufacturing Poland from Polkowice, a global-scale manufacturer of air-con solutions for automotive industry. Another huge success came in 2006 when the group struck a deal with the Neapco Europe factory (Visteon Polska S.A. at the time) in Praszka, the Opole region.

Multinational Capabilities

The Polkowice-based Service Centre is just one of many branches of the group, which, however present since 1996 only, has already made it to enter four different continents. This vast network is managed from Georgsberg, near Stainz, Austria, and comprises 8 tool management centres that, apart from Austria and Poland, are located in the countries such as Hungary, Germany, the Czech Republic and China. To top it off, the projects and branches in Russia, Slovakia, Brazil and Australia should be mentioned too. Brands that the TCM cooperates with speak for themselves, be it General Motors, VW, TRW, Neapco, ELAN and Flowserve. 21 tool management projects run all over the world call for numerous and highly trained personnel: as of December 2009 the company hires 516 people. Business of such impressive scale is bound to generate a suitably large turnover: last year its turnover topped the figure of 70 million EUR.

Exercise Your Choice

The services delivered by the TCM include: tool management, re-sharpening of machining tools, repair of tool holders and fittings, servicing of quick exchange chuck for thread cutting tools as well as tool trade. „The TCM is not merely a services or tools provider,” specifies Mr Polarski. “Our Customers are offered to participate in the production process. We aim to match our goals to those of the Client. By this I mean improving quality, a reduction in operation time and an increase in machines and production lines capacity, too.” These goals can be easily negotiated because the TCM is paid according to the system known as “cost per unit”, which means that the group is rewarded only for those items that have been turned out by the Clients according to their quality specifications. “From the Customer’s point of view, the main advantage of such a method of funding tool expenses lies in its simplicity. It is enough that you multiply the expected volume of production by the price per manufactured unit; this price is guaranteed by a relevant contract,” explains the TCM Vice President. The advantages of the company’s tool management policy can be presented in detail only if we go back to its inception and first lucrative contract with General Motors. Mr Polarski recalls it thus: “The boss at the GM decided to strike a deal with the TCM because, as he said, General Motors can manufacture cars that are the best in the world but they can’t specialise in everything. Hence the decision to hire experts to deal with specific means of production, machining tools included. Tool management outsourcing soon turned out to be an ideal recipe for our lasting success.”

Knocking Business into Shape

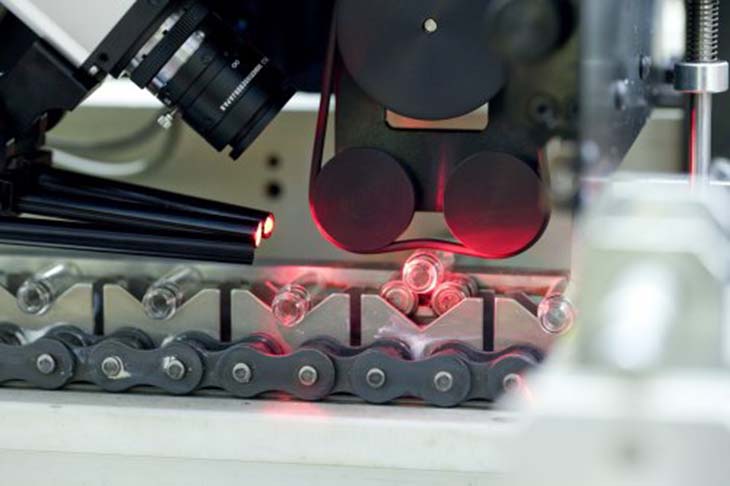

Every industry has its ups and downs. The recent economic crisis has affected outsourcers, too. There’s no denying that the demand for their services has slightly dwindled since 2008. According to Mr Polarski, this segment of the market will have to wait for revival until the producers’ equilibrium is restored and their growth is stimulated again. For this reason, just not to miss the boat, the TCM is already working on how to diversify the offer. Hence the idea to build the company’s standing on a range of activity, not just on tool management, however vital it would be for the company’s profit-making . It is necessary to seek after innovative and yet tested ideas. Resolved to return to its roots, the TCM has already created a plan to develop re-sharpening and servicing of machining tools. It is worth bearing in mind that these particular solutions helped the company to build its reputation among big Clients such as General Motors. Moreover, specialist revolving tools produced from tungsten carbide have been added to the offer. Last but not least, the TCM has introduced mechanisms to accelerate the process of machine grinding and regeneration, thereby reducing its length to 10 hours or so from the delivery. The TCM Centre in Polkowice guarantees that tools regenerated there will be like new again, this being achieved thanks to optimised processing and skilled personnel.

Message to Customers

These innovations has become an inherent part of the company’s long term strategy, which is best summarised by two punchy and convincing slogans. The first one that reads “top of mind” has been in the company since its inception. “Whenever our Clients contemplate the idea of hiring a tool management outsourcer, we want them to think of the TCM,” explains Mr Polarski. “Passion for tools” is the second slogan. “Invented thanks to brainstorming among our employees, it best expresses out attitude to work,” explains Mr Polarski. “We achieved top notch quality of our services due to several factors combined, including top quality means of production and the personnel being conscientious and responsible. They know for a fact that doing your best is worth a try as it directly results in Customer satisfaction. Its importance can hardly be overestimated.”

Polish Branch in Close-up

A word devoted exclusively to the Polkowice branch. Every month the Service Centre located there grinds and sets approx. 11,000 and 15,000 tools respectively for approx. 60 different Customers. 74 people onboard, they are top specialists, who, however trained for the group and by the group, completed their apprenticeship a long time ago. Nowadays they are considered to be the ones who set company standards. For many years the TCM Poland had been the first in the group to generate the highest turnover. And even though the branch lost its pole position in terms of profit-making to its Chinese counterpart (this should come as no surprise, though, considering Chinese market capacity), they are still the first to provide training for the TCM colleagues from abroad. The TCM Poland fails to export products, admittedly, but their services have nonetheless managed to find regular Customers in the Czech Republic, Germany and Luxembourg. “Here in Polkowice, we pay particular attention to partnership and teamwork. We also do our best to cater for our personnel’s needs as well as to create friendly atmosphere,” says Mr Polarski.

Look to Your Laurels

“We prefer not to see our Clients in terms of being more or less important. For that matter, we appreciate every single prize awarded by them,” declares the TCM Vice President. The TCM’s extensive collection of honours includes:

The Supplier of the Year title granted three times by General Motors,

The Supplier of Outsourcing Excellence Award title granted twice by Shanghai Volkswagen Powertrain,

The Supplier of the Year granted by Ford Motor Company, Brazil, in 2003,

First place in the Top of Styria 2006 competition, awarded for innovative solutions.

Moreover, the business takes pride in being in compliance with ISO 9001:2008 and Legalna Firma (Lawful Company) certificates. Awarded by BKK Invest, Microsoft and Autodesk, the latter confirms that there is only genuine software installed on the TCM’s computers.