«Metallurgical plant «Electrostal» JSC, one of the leading metallurgical enterprises specializing in special-purpose steels and alloys production for industries defining the status of Russia as a great maritime, aerospace and power-generating country, celebrated its 100th Anniversary in 2017.

How it all began

Metallurgical plant «Electrostal» was founded during the First World War, when Russia was in desperate need of high-quality steel in large amounts to produce ammunition and weapons, while there was no such domestic manufacture in Russia. It was Nikolay Alexandrovich Vtorov – an outstanding industrialist, financier, thinker, benefactor and patriot – who came to grips with this challenge of national importance. It took only a year to build a plant, which was one-of-a-kind in Russia. The first melt of high-quality steel by means of an advanced electrical metallurgy technique took place on November 17, 1917. Since then, the enterprise has been proudly named a flagship of national quality metallurgy. The entire history of the company has been strongly associated with the notion “the first”. In 1923 the first stainless steel in the country was melted here; a year later the first magnetic steel melt took place. Since 1926 «Electrostal» produces high strength ball-bearing steel. In 1932 the metallurgists of Electrostal mastered the technology for NiCr alloy production for electronic engineering. Thus, the USSR did not have to buy NiCr wire for electrical furnaces form the USA, which saved about 10 mln. rubles in gold. In autumn 1935, five-point stars made of high-alloyed stainless steel and red copper were installed on the towers of Kremlin. In May 1937 Kremlin decided to replace the steel stars with ruby stars with translucent lighting, which could resist corrosion and storms as the stars’ frame was made of stainless steel manufactured by «Electrostal». Having undergone only two restorations, the frame still remains untouched by time and preserves the steel of «Electrostal». An unprecedented non-stop flight of Chkalov, Baidukov and Belyakov along the route Moscow-Kamchatka-Udd Island made it into the history of Russian aviation in summer 1936. The aviators covered a distance over nine thousand kilometers and stayed in the air for more than 56 hours. The airplane was equipped with an engine M34-P manufactured from steel of «Electrostal». The closed-die forging shop of «Electrostal» produced forgings for all main parts of the engine, including crankshaft, three-lobes rotor head, gear shaft and piston rods. «Electrostal» plant was bravely fighting in the Second World War together with the whole country. The steel of «Electrostal» was used to produce aircraft IL-2, tanks T-34 and multiple launch rocket system «Katyusha».

The post-war years

Post-war years were no less challenging for the plant-laboratory, as the leading specialists in metallurgy called «Electrostal». The company developed technologies for melting heat-resistant and precision alloys, thermostatic bimetals, alloys with specific properties for instrumentation, radio engineering and communication equipment. «Electrostal» was the first to implement in commercial production the refining remelting process, vacuum metallurgy techniques, and advanced technologies of metal conversion which allow to manufacture steel products of exceptional qualitative characteristics. Supplying steel to all key hi-tech industries, «Electrostal» contributes to the economic and defense potential of the country.

Professional equipment,

reliable long - term partners

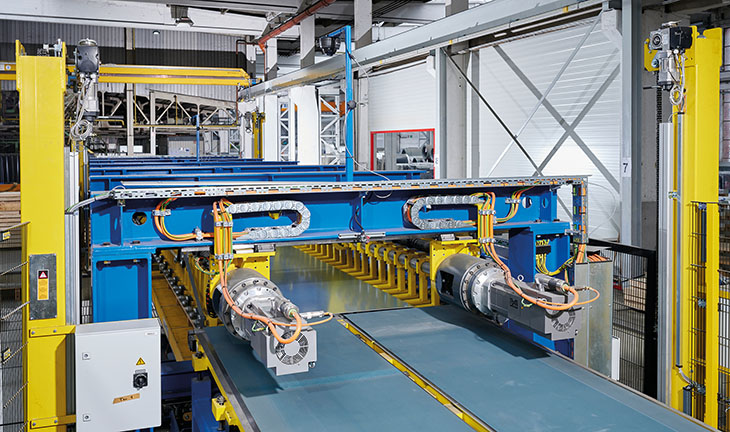

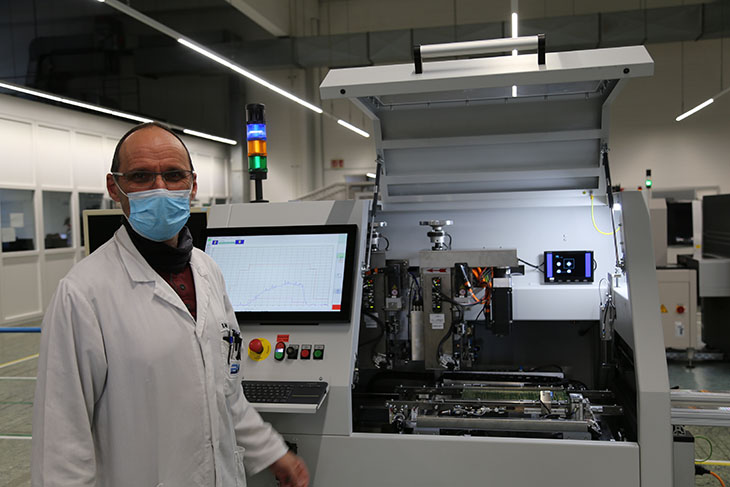

«Metallurgical plant «Electrostal» JSC keeps the lead in Russian special metallurgy with a unique equipment fleet which includes open induction and arc furnaces, ladle treatment unit, VIM and VAR furnaces, ESR, electron-beam and plasma-arc remelting furnaces with combined with a wide range of rolling, forging and machining plants, and forms a full production cycle from steel melting to finished product manufacture in various batch volumes. For the last five years, during the high-scale investment program implementation «Electrostal» has put in operation a range of equipment produced by the top manufacturers of Germany, the USA, Taiwan, and Israel. In steelmelting shops, a vacuum induction and electroslag remelting furnaces supplied by Consarc (USA), a vacuum-arc remelting furnace by ALD (Germany), and an open induction furnace FS-10 made by ABP (Germany) have been installed. A high-speed press 16 MN capacity and a new radial forging machine made by SMS MEER (Germany) have been commissioned and put into operation. A brand-new production line for deep conversion of special steels and alloys, including ring-rolling mills manufactured by SMS MEER and Siempelkamp, closed-die forging press 200 MN capacity (Siempelkamp) equipped with manipulator manufactured by GLAMA (Germany), automated heat treatment line with a fleet of furnaces supplied by Electrotherm (Israel), automated NDT lines for dye penetrant testing (ATG, Czech Republic) and ultrasonic testing (Scanmaster, Isreal) and other state-of-the-art machines have been installed. Also, a tool shop equipped with versatile turning lathes, mill cutters и finishing equipment, vertical and horizontal CNC lathes, as well as CNC EDM units has been created. Total investments amounted to over 150 million euros. Apart from that, we have upgraded our power supply facilities, laboratory facilities, resolved numerous environmental issues, and significantly improved working conditions. Quality Management System of the company is certified compliant with international standards ISO 9001 and AS/EN/JISQ 9100.

New production, new possibilities

Having set up a totally new production of rings, disks, shafts and other articles in the workshop for deep conversion of special steels and alloys, “Electrostal” has completely changed the product manufacture concept. Formerly being a billet supplier, it turned into a manufacturer of finished parts for engine building plants, hydroelectric power plants, nuclear power plants, oil & gas industry etc. Since April 2016, the deep conversion shop has reached the target performance values, and then exceeded them. Today, a quarter of all monthly marketable products of the company is produced in the new complex. We are currently developing new technical and technological possibilities to expand the range of high value-added products and ramp up their production. Electrostal produces special steels and alloys with unique properties. For instance, there is no equivalent to production of such product types as rolled sections with special properties from resistant alloys; nickel containing thin rolled sheet with special properties; wire from resistant alloys; strip and wire from precision alloys. «Metallurgical plant «Electrostal» JSC supplies more than 2750 product types in compliance with normative documentation developed in-house and technical specifications developed by industry research institutes in collaboration with the plant. The range of exclusive products manufactured by «Electrostal» comprises over 400 items. The company’s classification of steel grades ЭИ, ЭП, ЭК is widely-known both at the domestic and international markets. The main consumers of Electrostal’s products are aerospace complex enterprises, military industrial complex, power engineering plants, automotive industry, machine and instrumentation building plants, nuclear and ship-building industries. The reality of contemporary times, when there is certainty in accelerated development of the national aviation and engine-building industry, power engineering, oil & gas, sets new challenges and goals which are impossible to achieve without close cooperation with scientists and design engineers who develop new materials and power plants, and with consumers of «Electrostal»’s products. Adopting the policy of maximum transparency, «Electrostal» informs the customers about the current economic and financial climate in the company, prospects for development, real achievements in technological advancements, production facilities upgrade etc. Since 2014 «Metallurgical plant «Electrostal» JSC being a member of Aircraft Engine Building Union, international organization created in May 1991 and consolidating practically all Russian R&D institutions, design bureaus and factories participating in designing advanced engines, their production and maintenance, often welcomes main specialist and heads of organizations participating in design and development of advanced engines, their production and maintenance.

Within the framework of Aircraft Engine Building Union meetings conducted on site of «Electrostal», it is also possible for the foreign companies – members of the Union, substantially involved in «Electrostal» upgrading program, such as ATG (Czech Republic) and GLAMA (Germany) - to present their new developments. In 2016 «Metallurgical plant «Electrostal» JSC, together with transregional public organization «Association of Steelmakers» and Metallurgy and Metallurgical Science Research Board of Russian Academy of Sciences, for the first time hosted the XIVth International Congress of Steelmakers and Steel Manufacturers. The Congress was held to commemorate the 100th anniversary of first industrial electrical melt in Russia, which started the 100 years’ history of our enterprise. Every year the goals set for the staff become more and more complex. Professional expertise and high responsibility of our team allows accepting new challenges of modern times and deal with the issues of the 21st century technical realia.