Renault is restating its ambition to be present across the entire electric vehicle value chain, from technical architecture to motors and batteries.

Renault is supporting the development of a EV electrics industry in France as part of ongoing negotiations with LG Chem. A final agreement is expected in second-half 2013.

Ongoing negotiations concern:

· a new phase in the research and development of next-generation electrical batteries as part of a three-way draft agreement involving Renault, CEA (French Alternative Energies and Atomic Energy Commission) and LG Chem. This agreement targets the development of next-generation of batteries for production in early 2017.

· the LG Chem-led construction of a European battery factory in France. This factory would produce current-generation batteries from the end of 2015 and, from early 2017, the new-generation batteries resulting from the agreement between Renault, CEA and LG Chem.

Renault is thus restating its commitment to cut CO2 emissions and bring customers a range of electric vehicles at affordable prices.

Renault, LG CHEM and CEA are preparing to sign a three-way agreement in September concerning next-generation battery production.

In 2010, Renault and the CEA initiated a strategic partnership in the areas of clean vehicles and mobility for all. As part of this partnership, they signed several research agreements including a strategic cooperation contract for new battery technologies.

The joint Renault/CEA laboratory “advanced batteries”, set up as part of this agreement, has been tasked with developing new technology for lithium-ion batteries in the medium term. The studies conducted by the laboratory, which has received an annual budget of around €15 million since 2010, have now reached a sufficient stage of maturity to plan life-sized tests with a manufacturer.

In consequence, a three-way agreement between Renault, CEA and LG Chem is currently being finalized and should be signed next September. This agreement complements the studies currently under way between Renault and the CEA, which have a broader reach, and will concern only the development of next-generation batteries. These batteries will deliver higher performance in terms of durability, and fast-charging capacity. LG Chem, which is recognized as a leading global player in electric batteries, will provide its technological expertise in this field, acquired over a period of over 15 years. To date, LG Chem has filed more than 6,000 patents.

Renault supports the founding of a European battery factory in France

In view of today’s economic situation, Renault is keen to build ties with a blue-chip partner able to invest in a battery factory that would meet the needs of European markets. As part of ongoing negotiations, Renault is supporting the idea of a battery factory in France to be managed by LG Chem.

The original location must now be reviewed. This is because the site to be selected jointly by Renault and LG Chem must have the potential to expand in the longer term in order to produce electrodes, and must therefore be able to increase capacity. Electrodes are a key component of electric batteries. Their production involves advanced technologies with strict environmental requirements, particularly in terms of vibrations.

Moreover, wherever the factory is located, it must be able to easily serve all European markets while minimizing logistics costs. The production capacity and jobs offered by this factory should be higher than in the original project.

IN BRIEF: RENAULT AND ELECTRIC VEHICLES

· The Renault-Nissan Alliance plans to invest €4 billion in electric vehicles before 2015 and to sell 1,500,000 electric vehicles overall before 2016.

· Renault is currently European leader in electric vehicle sales.

· Renault is the only manufacturer to offer a full range of four electric vehicles: Kangoo Z.E., Fluence Z.E. (with AESC* batteries), Twizy and ZOE (with LG Chem batteries).

· With the production of ZOE at Flins (France) and Kangoo Z.E. at Maubeuge (France), 80% of the electric vehicles sold worldwide by Renault will be produced in France in 2015.

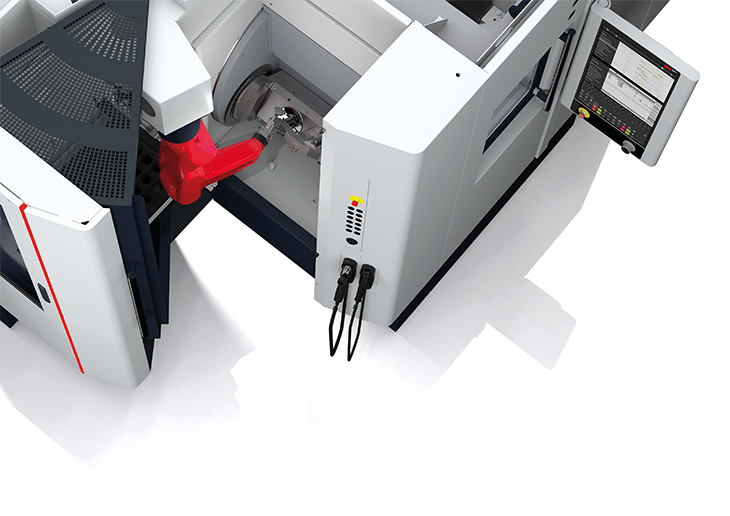

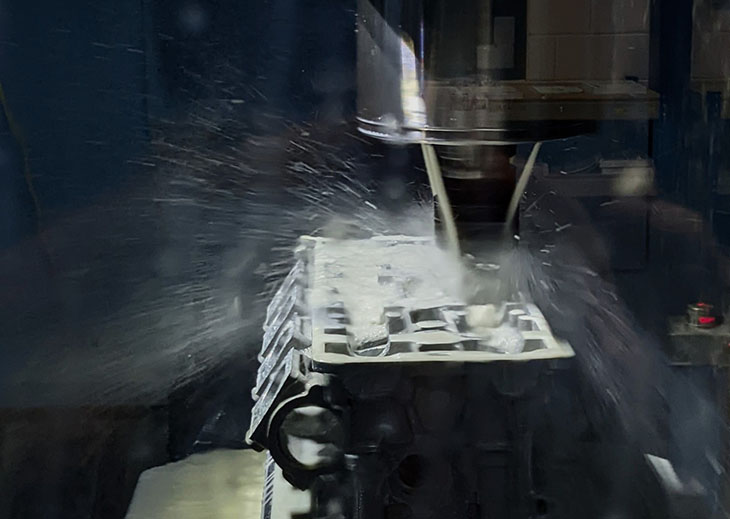

· The third-generation electric motor will be built at Cléon from 2013.

* AESC is the joint-venture set up by Nissan and NEC