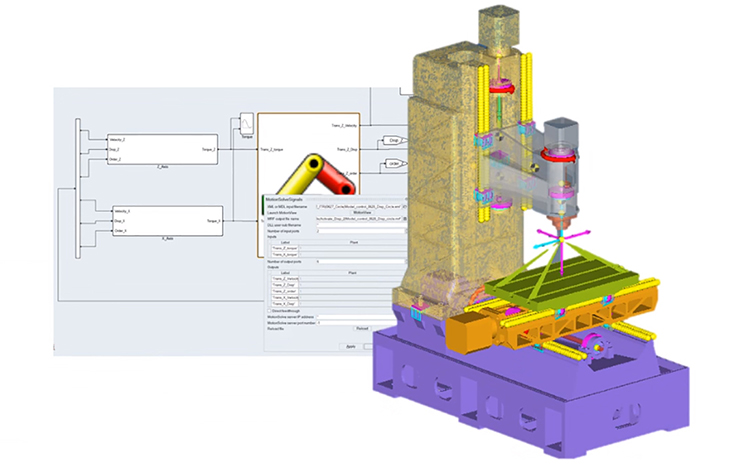

Thanks to its rigid press body, the Smartline is capable of producing high-precision drive components for the e-Golf and e-Up!

Göppingen/Kassel-Baunatal, July 11, 2016 – Schuler presses are no strangers to Volkswagen in the Kassel facility: they stamp out body and structural parts for the Group’s various vehicles every second of the day. For two particular models – the e-Golf and e-Up! – a Schuler line is now also being used to produce drive components. The Smartline blanks and punch-bundles laminations which are then assembled to make motors for these electric vehicles.

The machine has been in operation since August 2014 in the Kassel Manufacturing division. These can be directly processed without any subsequent time-consuming work.

Volkswagen uses the Smartline to process sheet metal with thicknesses of just 0.3 millimeters – and even 0.2 millimeters are possible. The processing of thinner laminations enables the production of electric motors with lower eddy current losses and, as a consequence, increased efficiency and reduced power consumption.

With Smartline technology, die lives are significantly extended. Thus, while output is increased, part costs are reduced at the same time. Good die lives are a result of the extreme precision of the press with its play-free slide guiding system and high rigidity. The oil-tempered cast-iron body also significantly increases the thermal stability of the press. Despite having a press bed measuring 3.30 meters and weighing several metric tons, the high-precision machine works within tolerances of hundredths of a millimeter.

This is due in part to the dynamic depth penetration control developed by Schuler, which checks the depth of die penetration on every stroke and adjusts it where necessary. The whole process from measurement to adjustment takes just hundredths of a second. The Smartline is thus capable of using very long dies or reliably blanking extremely thin sheets which permit only minimal die clearance.