Italy has a leading role in the project, thanks to the coordination of University of Parma and to the contribution of Ecor Research, a company from Vicenza province.

A European team of researchers led by the University of Parma, together with a network of partner companies, including the company of Vicenza Ecor Research, is developing the first fluid-repellent, antibacterial, metal surface in the world, bringing us one step closer to production of appliances and machinery for the food industry self-cleaning.

The innovation aroused within the TresClean project (High throughput laser texturing of self-cleaning and antibacterial surfaces) promoted in the framework of the community program Horizon 2020. The team was inspired by the mechanisms with which some plants, such as Lotus, make their leaves fluid-repellent.

Leaves surfaces suggested the idea that it is possible to create, also in metals, structures that, by reducing wettability, can detect new functions such as the preventions of bacterial adhesion.

The application of this concept to metal elements creates a wide perspective of implementation for all those components sensitive to bacterial contamination, ranging from food industry to domestic and biomedical application.

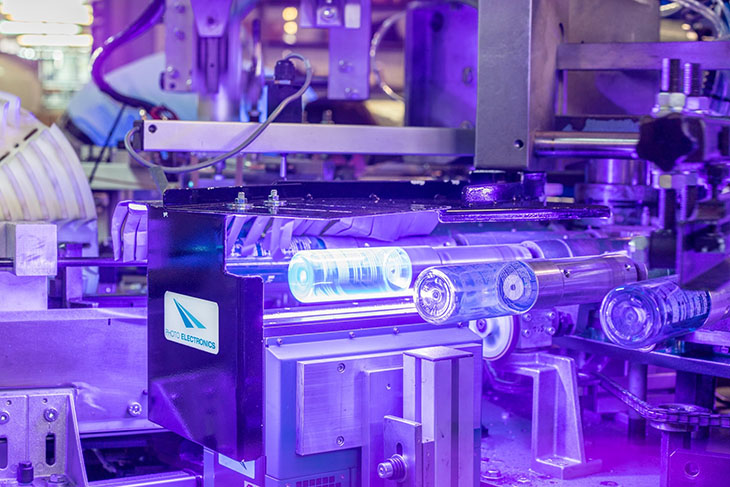

TresClean team uses high-average power ultrashort-pulsed lasers to create on metal sheets a surface topography conceived to duplicate the Lotus leaf surface and to prevent liquid adhesion. This topography is able to capture miniature pockets of air that minimize the contact area between the surface and liquids.

Professor Luca Romoli, Project Coordinator of TresClean explains: “Lotus leaves keep themselves clean thanks to particular surface texture enabling water to stay as spherical droplets by preventing ‘spreading’. Under these conditions, bacteria do not get a chance to stick because the contact with the metal surface and the liquid is reduced significantly. In this way, with laser it is possible to create on metal surfaces an antibacterial topography without adding chemicals.”

Metal surfaces undergo a specific laser marking process, using innovative optical devices for common industrial use: ultrashort-pulsed lasers, but with high-average power are used in combination with high-performance scanning heads by utilizing an innovative beam delivery method enabling movements of up to 200 m/s.

In this way, technology developed by TresClean is able to perform stainless steel surface marking of 500 square cm in less than 30 minutes. If compared with the technology existing in early 2015 in which production methods were able to obtain these specific structures at a rate of 0,6 square mm, TresClean in the same period of time, can produce 1000 square cm, making this technology 156 times quicker than before.

Professor Romoli estimates that TresClean could have its products ready within 2 years.

Initially aiming its product at machine parts for the food industry, TresClean hopes to make a significant impact on productivity: “Vats in milk factories need to be cleaned every 6-8 hours to avoid the exponential growth of bacteria. This hinders usage and therefore affects output” Romoli said.

“By saving hours per day in cleaning, it will yield an efficiency improvement stemming from fewer sterilization cycles and less cleaning time within production as a whole. This will also reduce energy consumption as a result of fewer cleaning phases making food production quicker, safer and more profitable”.

Professor Romoli sees long-term possibilities and implications for other sectors besides food farming industry.

The project received funds amounting to 3.3 million euro in the framework of the calls for H2020 Industrial Leadership program with the support of Photonics Public Private Partnership Support. The consortium is composed by the University of Parma as coordinator, the Italian company of Schio (Vicenza) Ecor Research, Universitaet Stuttgart (Germany), Centre Technologique Alphanov (France), RAYLASE AG (Germany), BSH Electrodomesticos Espana SA ( Spain) and Kite Innovation Limited (United Kingdom).

Within the research group, Ecor Research has contributed with its expertise in the field of characterization and functionalization of surfaces and in the design of a functional testing system that made it possible to analyse, in an environment similar to the industrial one, the properties of the treated surfaces with respect to the stated functions.

About Ecor Research

Ecor Research, founded in 1976 in Schio, near Vicenza, and still led by its founder, Sergio Lucietto, operates in the Food Packaging, Aerospace and Defense and Advanced Mechanics industry, it has a staff of 170 employees and a total turnover of 38 million euro.

The company deals with design, prototyping and production of components critical from health and safety point of view, assembly of electromechanical subsystems, construction and operation of test benches for the integrated simulation, co-design and engineering services.

Over the years, Ecor Research has obtained several certifications, both for system and process, highlighting the utmost attention to every quality aspect.

The system certifications are: ISO 9001, on quality management; ISO 14001 on environmental management; OHSAS 18001, on workers’ health and safety; AS / EN 9100, on aerospace industry quality.

Certification of special processes are: Nadcap Welding, on welding processes; Nadcap Heat Treatment on heat treatment processes; Nadcap Non-Destructive Testing, on non-destructive testing.

It has recently been accredited by ASTER (a consortium between the Emilia-Romagna Region, Universities, National public research institutes CNR, ENEA, INFN and the regional system of Chambers of Commerce, that, in partnership with business associations, promotes innovation of the regional production system) Ecor Campus, industrial research center of advanced type, based in Castelvetro di Modena.

It is an R&D Division who studies Reliability Engineering, with the creation of test benches for functional testing, and Surface Engineering, with the study of material properties.

Since December 2014, Ecor Research has become part of Poema network, located in Avellino. The industrial district of 12 companies, operating in the Aerospace and Defense sector, aims to improve the efficiency and quality of aircraft engines. European Microfusioni Aerospaziali S.p.A, a company 100% owned by Rolls-Royce plc. is leading this industrial agreement.