More consistent results, higher efficiency and cleaner work pieces for the automatic de-powdering and cleaning of 3D printed components

With its numerous technical features, the latest generation of the S1 post processing system from AM Solutions – 3D post processing technology is setting new standards for de-powdering and cleaning of 3D printed components. These include the swivel-mounted rotary basket for ergonomic loading/unloading and prevention of contaminating the machine environment, swivel-mounted blast nozzles preventing re-contamination of treated parts and a design that is in complete compliance with ATEX standards. Of course, the gentle and, at the same time, intensive processing, the easy and safe change of blast media and the easy switch from automatic to manual operation ensure efficient and consistent high-quality processing results.

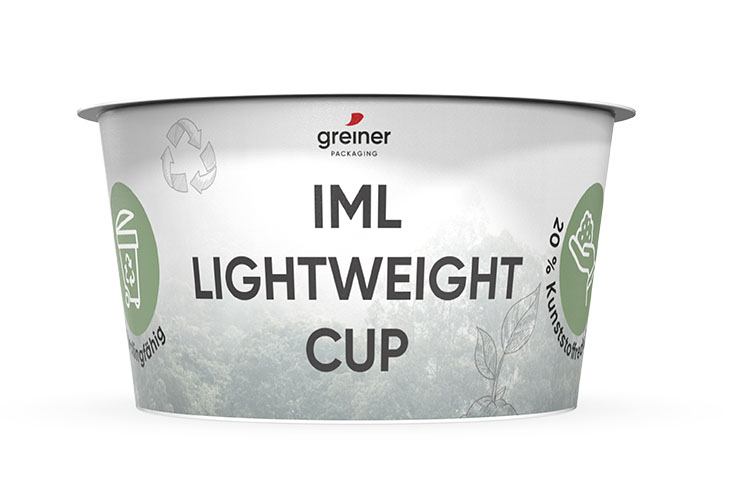

Plastic components printed with powder-based 3D printing systems require complete removal of residual powder and an excellent surface preparation. This is essential for the success of subsequent manufacturing operations like painting or coating. AM Solutions – 3D post processing technology, a division of the Rösler group and specialized in post processing, has completely re-designed its S1 surface treatment system. This cost-efficient plug-and-play unit is ideal for the automatic de-powdering and cleaning of small to mid-size work piece volumes.

The new machine design allows the easy switch from automatic to manual operation without time consuming re-tooling. This can be highly advantageous for processing of somewhat larger single components. All the operator has to do is to unlock the rotary basket and move it to the rear of the blast cabinet. This provides work space for the manual handling and blasting of somewhat larger components. The clever design ensures that the operator is not exposed to any moving parts so that no additional safety features are necessary.

Automated de-powdering – fast, reliable and consistent

The integrated rotary basket allows the fully automatic processing of batches up to 25 liters and a maximum batch weight of 50 kg. The special basket design ensures optimal distribution and mixing of the components during the blast operation. This, in combination with the pivoting blast nozzles, guarantees the effective and gentle blast treatment of the components in short cycle times. Depending on the finishing task, the shot blast operation can be run with either glass beads or a suitable plastic media. Once the blast cycle is complete, contrary to conventional cabinets, where the blast nozzles are tilted upwards, in the S1 the blast nozzles are automatically swiveled out of the basket. This prevents any powder accumulated on the blast nozzle holder to fall back into the basket and re-contaminate the cleaned components during the subsequent shakeout.

For loading and unloading the basket swivels to the large opening in the cabin front but remains completely within the blast chamber. This allows the ergonomic loading and unloading of work pieces without the risk of contaminating the immediate machine environment with powder.

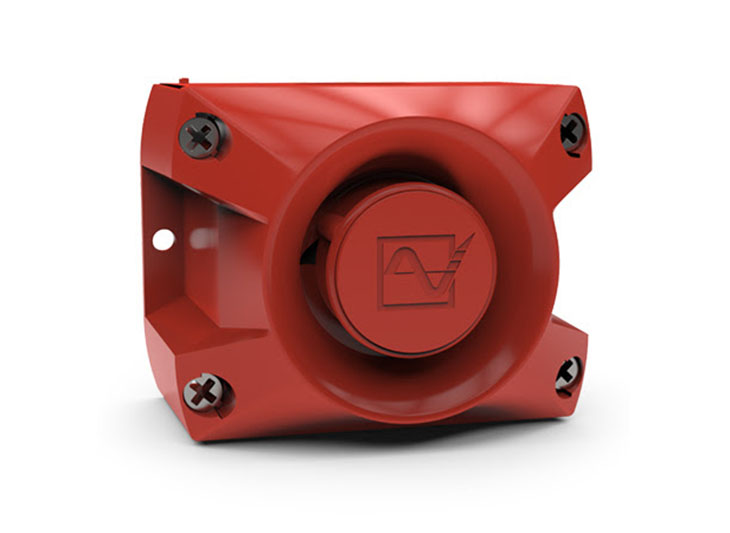

The PLC of the S1 allows the storing of multiple blast programs with work piece specific parameters like blast pressure and basket RPM. These parameters are continuously monitored during the complete process. They can be stored in the machine controls or transmitted to a higher level computer system. In case of deviations from the specified parameters the PLC provides an acoustic or visual warning.

Integrated health, work and component protection

Another significant feature of the S1 is that the inside of the cabinet and the rotary basket are lined with an antistatic polyurethane coating. The precisely defined shore hardness of the basket lining prevents any color contamination of the work pieces. The powder swirling around during the blast process is explosive. Equipment suppliers are frequently passing this potential problem on to the equipment operators by demanding that the amount of powder carried into the machine cannot exceed a certain limit. AM Solutions – 3D post processing technology has an resolved this issue by utilizing components like motors and valves that are in compliance with ATEX standards.

Because of the relatively low noise emission of <=80 dB(A) - when blasting with 3 bar - and the air-tight machine doors the S1 can be operated without safety glasses and noise protection.

Effective media classification for consistently good process results

Besides control panel, PLC, dust collector and easily exchangeable media bin the compact S 1 post processing system has also an integrated media classification system. This consists of a cyclone and a screen vibrator for discharging dust and broken down media. Only a consistently high media quality ensures high quality shot blast results.

Finally, the machine is equipped with two viewing windows (for automatic and manual blasting). An “air curtain” prevents the blast media from hitting the window panes.

With its well thought out technical design the new S1 meets not only the highest standards for process safety and efficiency but also for protection of the work place and the health of the employees.

www.solutions-for-am.com

For over 80 years the privately owned Rösler Oberflächentechnik GmbH has been actively engaged in the field of surface preparation and surface finishing. As global market leader we offer a comprehensive portfolio of equipment, consumables and services around the mass finishing and shot blasting technologies for a wide spectrum of different industries. Our range of about 15,000 consumables, developed in test centers located all over the world, specifically serves our customers for resolving their individual finishing needs. Under the brand name AM Solutions we offer numerous equipment solutions and services in the area of additive manufacturing/3D printing. Last-but-not-least, as our central training center the Rösler Academy offers practical, hands-on seminars to the subjects mass finishing and shot blasting, lean management and additive manufacturing. Besides the German manufacturing locations in Untermerzbach/Memmelsdorf and Bad Staffelstein/Hausen the Rösler group has a global network of 15 manufacturing/sales branches and 150 sales agents.

For more information please visit: www.rosler.com